Lignin/butadiene styrene rubber composite solid particle and synthesis method thereof

A technology of styrene-butadiene rubber and solid particles, which is applied in the field of rubber composite materials, can solve the problems of small particle size of lignin/styrene-butadiene rubber composite materials, equipment failure, and lack of cross-linking characteristics, so as to improve the thermal oxidation resistance. Effects of aging properties, reduced equipment failure and rubber loss, good physical and mechanical properties and resistance to thermal oxidative aging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

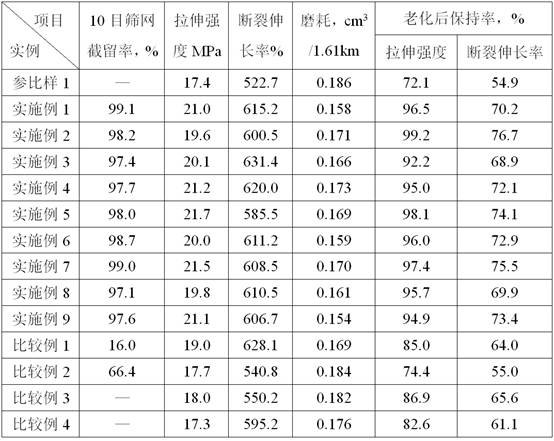

Examples

Embodiment 1

[0041] (1) Dissolve 10g of alkali lignin in 100g of 2wt% sodium hydroxide solution, then add 1.9g of phenol and 3g of 37wt% formaldehyde solution, and stir for 2 hours at 80°C and 500rpm; 10% of styrene-butadiene rubber latex with a solid content of 24wt% was added, and the stirring reaction was continued for 5 minutes to obtain a mixed solution.

[0042] (2) Configure a sodium chloride solution with a concentration of 0.2wt%. According to the mass ratio of the electrolyte solution to the mixed solution in step (1) of 2:1, under the conditions of 60°C and 150r / min, mix the mixed solution at 10mL / s The speed is added to the sodium chloride solution, and the sulfuric acid solution with a concentration of 10wt% is added at the same time to keep the pH value of the whole system between 3-5. After the reaction, use 10-mesh and 200-mesh stainless steel screens to filter and separate the lignin / styrene-butadiene rubber composite solid particles in an overlapping manner, wash with wat...

Embodiment 2

[0044] (1) Dissolve 10g of alkali lignin in 100g of 1wt% potassium hydroxide solution, then add 1.3g of phenol and 2.1g of 37wt% formaldehyde solution, and stir for 2 hours at 60°C and 100rpm; 5% of the rubber mass was added to styrene-butadiene rubber latex with a solid content of 20wt%, and the stirring reaction was continued for 5 minutes to obtain a mixed solution.

[0045] (2) Configure a potassium chloride solution with a concentration of 0.1wt%, according to the mass ratio of the electrolyte solution and the mixed solution at 1:1, add the mixed solution at a rate of 5mL / s at 30°C and 50r / min In potassium chloride solution, add the sulfuric acid solution of concentration 1wt% simultaneously, keep whole system pH value between 3-5. After the reaction, use 10-mesh and 200-mesh stainless steel screens to filter and separate the lignin / styrene-butadiene rubber composite solid particles in an overlapping manner, wash with water to neutrality, and recover the composite particl...

Embodiment 3

[0047] (1) Dissolve 10g of alkali lignin in 20g of 10wt% sodium hydroxide solution, then add 3.2g of phenol and 4.7g of 37wt% formaldehyde solution, stir and react at 90°C and 1000rpm for 3h; Add styrene-butadiene rubber latex with a solid content of 30wt% to 30% of the mass of styrene-butadiene rubber, and continue to stir and react for 10 minutes to obtain a mixed solution.

[0048] (2) Configure a sodium sulfate solution with a concentration of 1.0wt%. According to the mass ratio of the electrolyte solution to the mixed solution in step (1) of 3:1, under the conditions of 80°C and 300r / min, mix the mixed solution at a rate of 30mL / s Add the sodium sulfate solution at a high speed, and add the sulfuric acid solution with a concentration of 20wt% at the same time to keep the pH value of the whole system between 3-5. Filter and separate phenolic resin modified lignin / styrene-butadiene rubber composite solid particles, wash with water until neutral, and dry lignin / styrene-butad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com