A template-free preparation of ceo 2 mesoporous materials method and ceo 2 Mesoporous materials

A mesoporous material, template-free technology, applied in the direction of cerium oxide/cerium hydroxide, lanthanide oxides/hydroxides, rare earth metal oxides/hydroxides, etc., can solve the complex preparation process of mesoporous materials, High cost, high energy consumption and other problems, to achieve the effect of saving the roasting process, low cost and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] The template-free preparation of CeO in this embodiment 2 Methods for mesoporous materials, including:

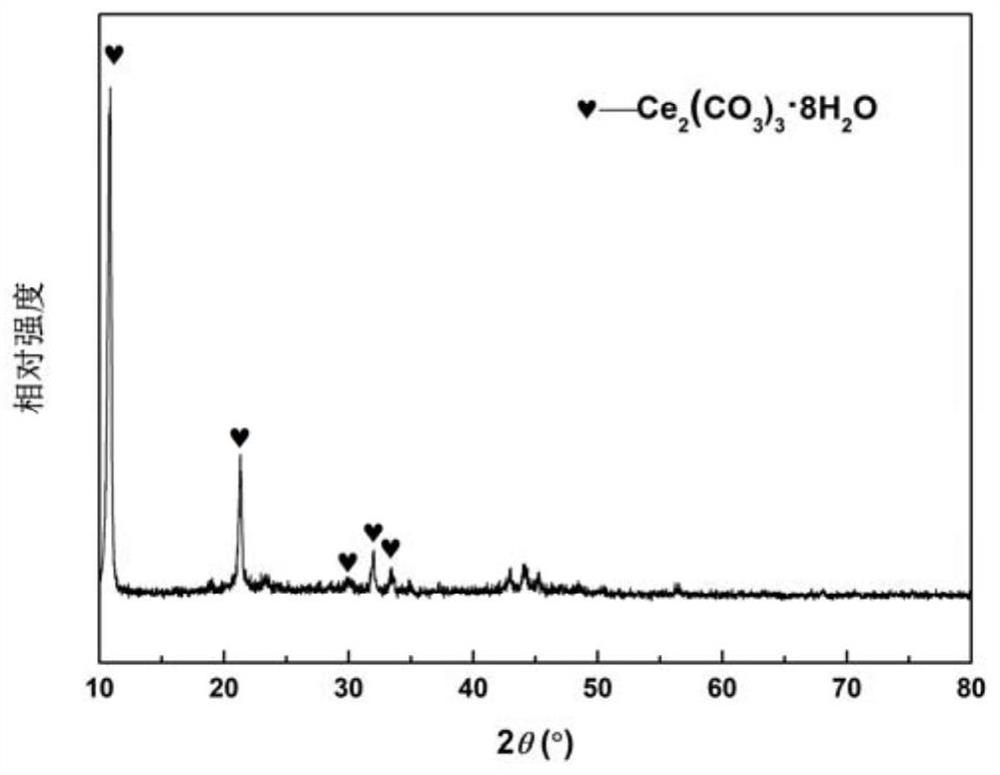

[0031] At room temperature, the Ce(NO 3 ) 3 ·6H 2 O dissolves in distilled water to form Ce 3+ aqueous solution, followed by NH 4 HCO 3 Added to continuously stirring Ce 3+ In aqueous solution, a white precipitate is formed immediately: the first precursor. Take H 2 o 2 Add it into the solution, continue to stir for 30 minutes, and age for 3 hours to obtain the second precursor. Ce(NO 3 ) 3 ·6H 2 O, NH 4 HCO 3 and H 2 o 2The mass ratio is 1:0.64:0.35.

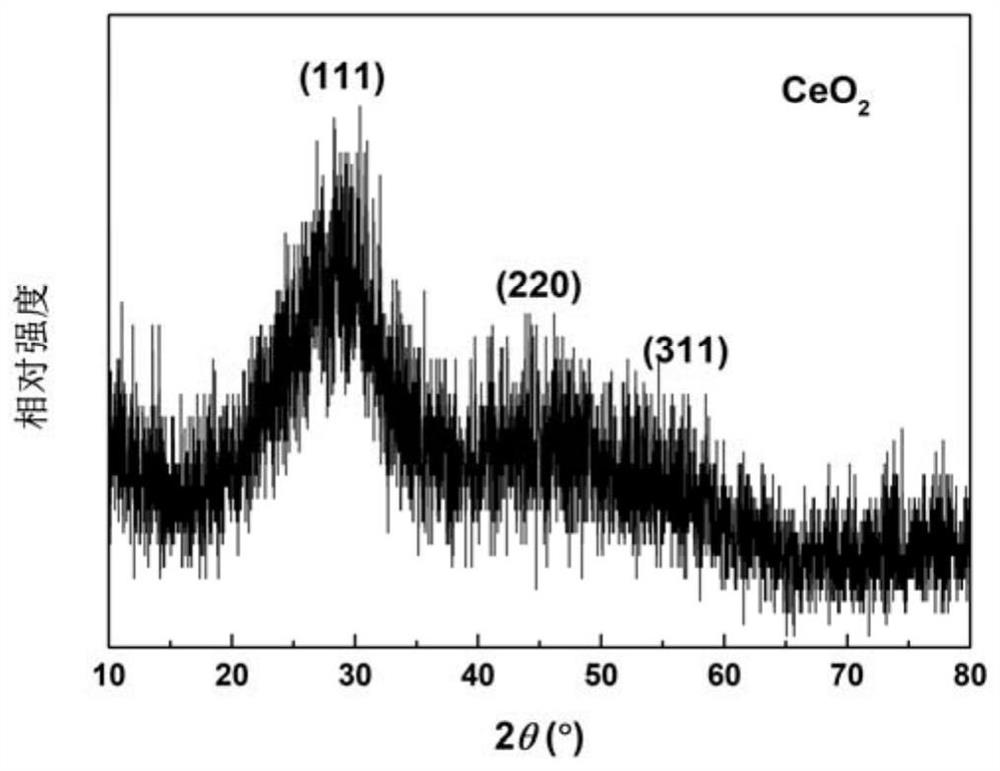

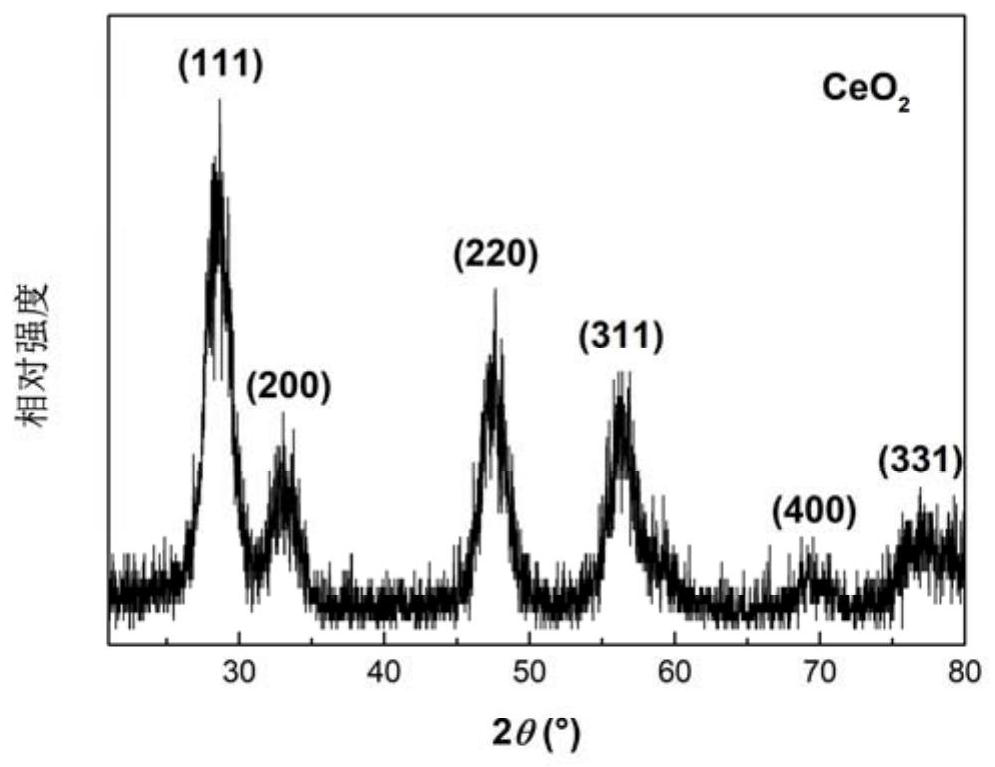

[0032] The second precursor was separated by centrifugation and washed 3 times with distilled water, after which the solid was dispersed in distilled water. The mass ratio of the second precursor to the distilled water is 1:36.3. The obtained solution was transferred to a hydrothermal kettle with a capacity of 50 mL and kept at 180 °C for 28 h. After the hydrothermal kettle was cooled, the collecte...

Embodiment 2

[0035] The template-free preparation of CeO in this embodiment 2 Methods for mesoporous materials, including:

[0036] At room temperature, the Ce(NO 3 ) 3 ·6H 2 O dissolves in distilled water to form Ce 3+ aqueous solution, followed by NH 4 HCO 3 Added to continuously stirring Ce 3+ In aqueous solution, a white precipitate is formed immediately: the first precursor. Take H 2 o 2 Add it into the solution, continue to stir for 30 minutes, and age for 3 hours to obtain the second precursor. Ce(NO 3 ) 3 ·6H 2 O, NH 4 HCO 3 and H 2 o 2 The mass ratio is 1:0.91:1.73.

[0037] The second precursor was separated by centrifugation and washed 3 times with distilled water, after which the solid was dispersed in distilled water. The mass ratio of the second precursor to the distilled water is 1:50.8. The obtained solution was transferred to a hydrothermal kettle with a capacity of 50 mL and kept at 220 °C for 20 h. After the hydrothermal kettle is cooled, collect the ...

Embodiment 3

[0040] The template-free preparation of CeO in this embodiment 2 Methods for mesoporous materials, including:

[0041] At room temperature, the Ce(NO 3 ) 3 ·6H 2 O dissolves in distilled water to form Ce 3+ aqueous solution, followed by NH 4 HCO 3 Added to continuously stirring Ce 3+ In aqueous solution, a white precipitate is formed immediately: the first precursor. Take H 2 o 2 Add it into the solution, continue to stir for 30 minutes, and age for 3 hours to obtain the second precursor. Ce(NO 3 ) 3 ·6H 2 O, NH 4 HCO 3 and H 2 o 2 The mass ratio is 1:0.73:1.21.

[0042] The second precursor was separated by centrifugation and washed 3 times with distilled water, after which the solid was dispersed in distilled water. The mass ratio of the second precursor to the distilled water is 1:43.6. The obtained solution was transferred to a hydrothermal kettle with a capacity of 50 mL and kept at 200 °C for 24 h. After the hydrothermal kettle was cooled, the collect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com