Solar cell encapsulation adhesive film

A technology for solar cells and encapsulation films, used in adhesives, film/sheet adhesives, films/sheets without carriers, etc., which can solve the problem of poor light stability and low spectral utilization of organic fluorescent agents , affecting the light transmittance of the film, etc., to improve the connection stability, improve the safety of use, and improve the overall stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

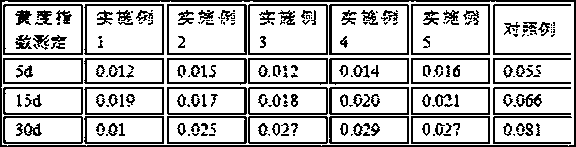

Examples

Embodiment 1

[0019] A solar cell encapsulation adhesive film, made by the following method: 100 parts by weight of matrix resin, 0.2 parts by weight of light conversion agent, 0.02 parts by weight of peroxide initiator, 0.8 parts by weight of crosslinking agent, 0.05 parts by weight Parts by weight of auxiliary crosslinking agent, 0.5 parts by weight of tackifier, 0.05 parts by weight of light stabilizer containing reactive groups, 0.05 parts by weight of antioxidant, 0.05 parts by weight of hydrophobic agent, 0.02 parts by weight of anti-oxidant After the acid agent is mixed evenly, it is granulated with a twin-screw extruder, and the finished single-screw extruder is extruded and cast to form a film.

[0020] Wherein, the crosslinking agent is tert-butylperoxycarbonate-2-ethylhexyl, and the auxiliary crosslinking agent is trimethylolpropane tri(methacrylate).

[0021] Among them, 4-acryloyloxy-2,2,6,6-tetramethylpiperidinol ester is selected as the light stabilizer containing reactive gr...

Embodiment 2

[0027] A solar cell encapsulation adhesive film, obtained by the following method: the matrix resin of 100 parts by weight, the light conversion agent of 0.4 parts by weight, the peroxide initiator of 0.05 parts by weight, the crosslinking agent of 1.2 parts by weight, 0.08 parts by weight Parts by weight of auxiliary crosslinking agent, 0.8 parts by weight of tackifier, 0.08 parts by weight of light stabilizer containing reactive groups, 0.12 parts by weight of antioxidant, 0.12 parts by weight of hydrophobic agent, 0.05 parts by weight of anti-oxidant After the acid agent is mixed evenly, it is granulated with a twin-screw extruder, and the finished single-screw extruder is extruded and cast to form a film.

[0028] Wherein, the crosslinking agent is tert-butylperoxycarbonate-2-ethylhexyl, and the auxiliary crosslinking agent is trimethylolpropane tri(methacrylate).

[0029] Among them, 4-methacryloyloxy-2,2,6,6-tetramethylpiperidinol ester is selected as the light stabilize...

Embodiment 3

[0036] A solar cell encapsulation adhesive film, obtained by the following method: the matrix resin of 100 parts by weight, the light conversion agent of 1 part by weight, the peroxide initiator of 0.8 parts by weight, the crosslinking agent of 4 parts by weight, 2.5 parts by weight Parts by weight of auxiliary crosslinking agent, 2.5 parts by weight of tackifier, 2.5 parts by weight of light stabilizer containing reactive groups, 2 parts by weight of antioxidant, 1 part by weight of hydrophobic agent, 0.5 parts by weight of anti-oxidant After the acid agent is mixed evenly, it is granulated with a twin-screw extruder, and the finished single-screw extruder is extruded and cast to form a film.

[0037] Wherein, the crosslinking agent is tert-butylperoxycarbonate-2-ethylhexyl, and the auxiliary crosslinking agent is trimethylolpropane tri(methacrylate).

[0038] Among them, 4-methacryloyloxy-1,2,2,6,6-pentamethylpiperidinol ester is selected as the light stabilizer containing r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com