Anhydrous Dyeing Method for Dyeing and Fixing Cotton Fabrics Step by Step

A technology for anhydrous dyeing, cotton fabrics, applied in the field of printing and dyeing, can solve problems such as emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

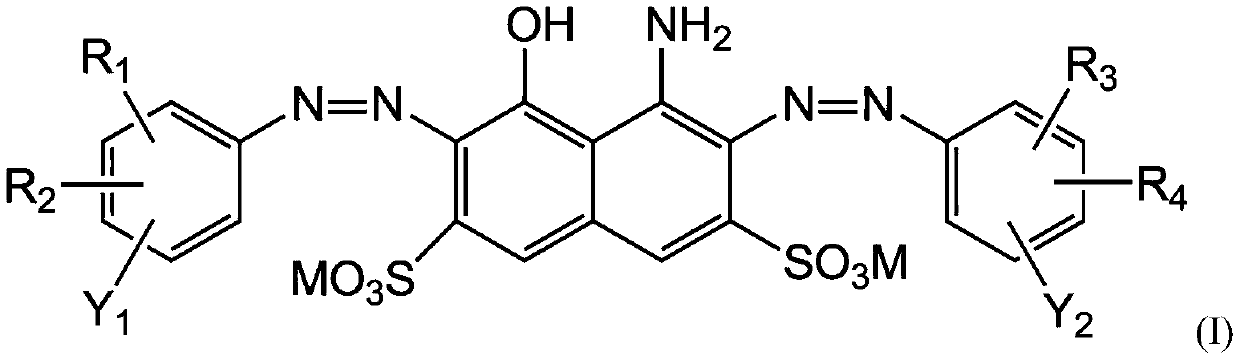

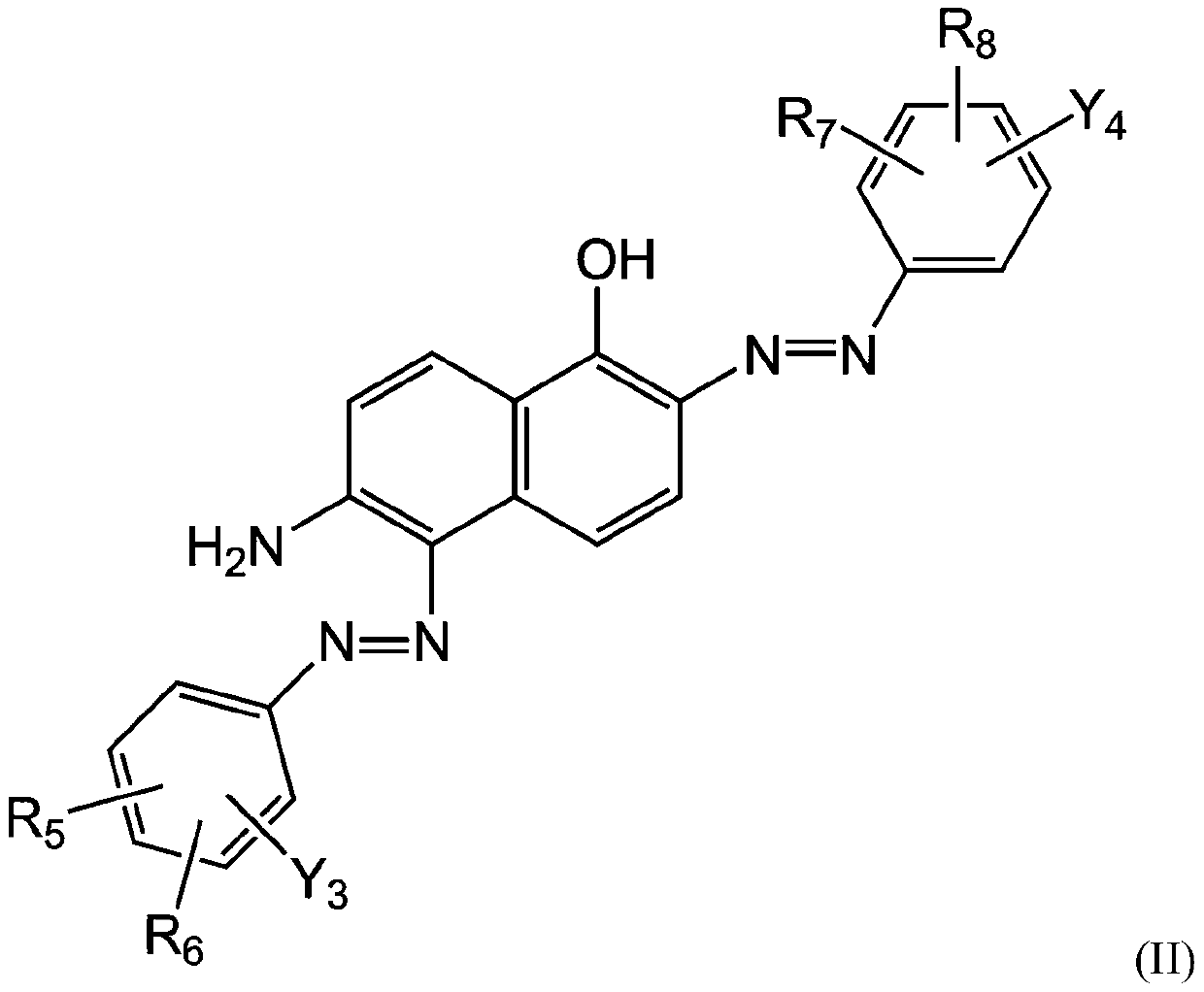

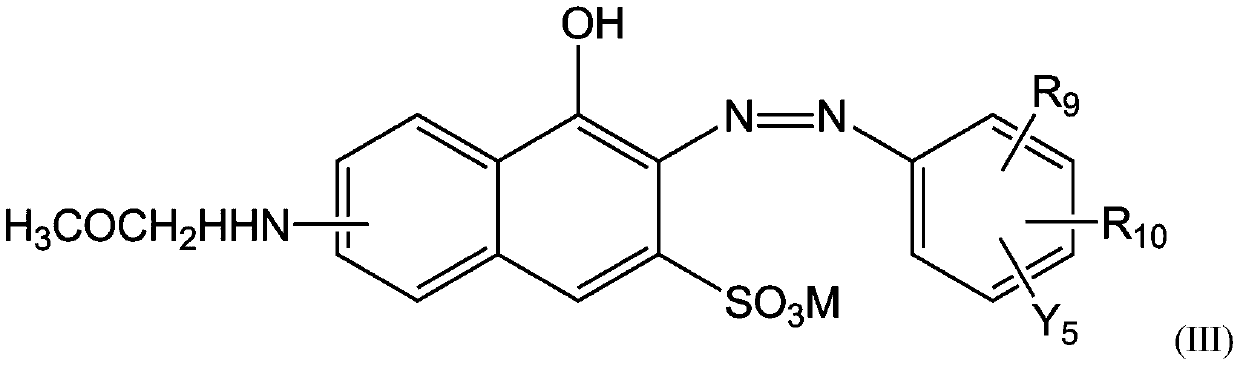

[0186] Reactive black dye composition is formed by mixing 65% of the dye compound represented by the formula (I-1), 25% of the dye compound represented by the formula (II-1), and 10% of the dye compound represented by the formula (III-1) . The reactive black dye composition was dissolved in an anhydrous solvent of ethylene glycol monomethyl ether acetate and dimethyl sulfoxide at a volume ratio of 70:30 to obtain a dyeing bath. Then add the mixture of triethylenediamine and tetramethylguanidine to the anhydrous dye bath, the weight ratio of the two is 1.6:1; the amount of organic base added is 6g / L. Sonication yields a homogeneous anhydrous dye bath. A cotton fabric previously swollen with dimethyl sulfoxide with a swelling degree of 22% was placed in an anhydrous dyeing bath. The bath ratio of cotton fabric to anhydrous dyeing bath is 1:16g / mL. The dye dosage is 4o.w.f%. Heat up at a rate of 3°C / min, keep warm after reaching the target temperature of 85°C, and dye for 5 h...

Embodiment 2

[0188] Reactive black dye composition is formed by mixing the dye compound shown in 70% formula (I-1), 22% dye compound shown in formula (II-1), and 8% dye compound shown in formula (III-1) . The reactive black dye composition was dissolved in an anhydrous solvent of ethylene glycol monomethyl ether acetate and dimethyl sulfoxide at a volume ratio of 65:35 to obtain a dyeing bath. Then add the mixture of triethylenediamine and tetramethylguanidine to the anhydrous dye bath, the weight ratio of the two is 1.8:1; the amount of organic base added is 8g / L. Sonication yields a homogeneous anhydrous dye bath. A cotton fabric previously swollen with dimethyl sulfoxide with a swelling degree of 22% was placed in an anhydrous dyeing bath. The bath ratio of cotton fabric to anhydrous dyeing bath is 1:18g / mL. The dye dosage is 4o.w.f%. Heat up at a rate of 3°C / min, keep warm after reaching the target temperature of 90°C, and dye for 4 hours; cool to room temperature after dyeing, use...

Embodiment 3

[0190] Reactive black dye composition is formed by mixing the dye compound shown in 60% formula (I-1), 28% dye compound shown in formula (II-1), and 12% dye compound shown in formula (III-1) . The reactive black dye composition was dissolved in an anhydrous solvent of ethylene glycol monomethyl ether acetate and dimethyl sulfoxide at a volume ratio of 75:25 to obtain a dyeing bath. Then add the mixture of triethylenediamine and tetramethylguanidine to the anhydrous dye bath, the weight ratio of the two is 1.5:1; the amount of organic base added is 5g / L. Sonication yields a homogeneous anhydrous dye bath. A cotton fabric previously swollen with dimethyl sulfoxide with a swelling degree of 22% was placed in an anhydrous dyeing bath. The bath ratio of cotton fabric to anhydrous dyeing bath is 1:14g / mL. The dye dosage is 4o.w.f%. Heat up at a rate of 3°C / min, keep warm after reaching the target temperature of 80°C, and dye for 6 hours; cool to room temperature after dyeing, us...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com