Anchor rod construction process for ensuring safety and quality

An anchor construction and quality technology, which is applied in the installation of anchors, shaft equipment, shaft lining, etc., can solve the problems of vault cavity, continuous collapse cavity, hidden quality problems, etc., and achieve the effect of solving hidden safety hazards and ensuring construction quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] see Figure 1-3 , a bolt construction process that ensures safety and quality, the steps are as follows:

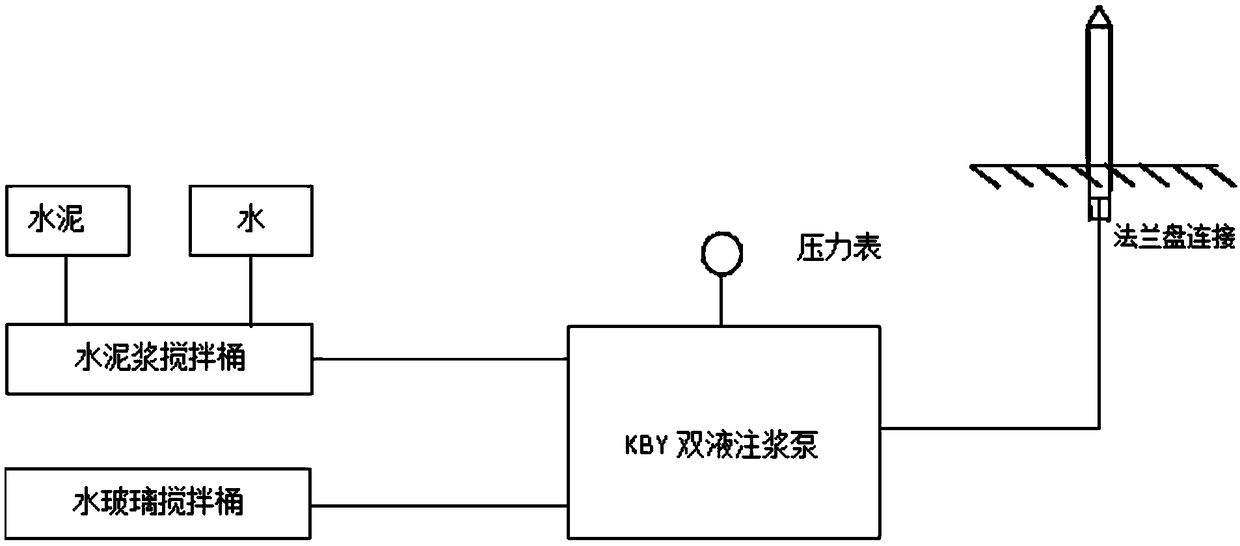

[0039] S1. Pre-construction preparations, including construction measurement and grout configuration. The surveyors must accurately determine and record the drilling hole position; the grout configuration is 10min solidification, 15min solidification, and 20min solidification double-fluid slurry ratio, according to the actual grouting situation, carry out slurry selection;

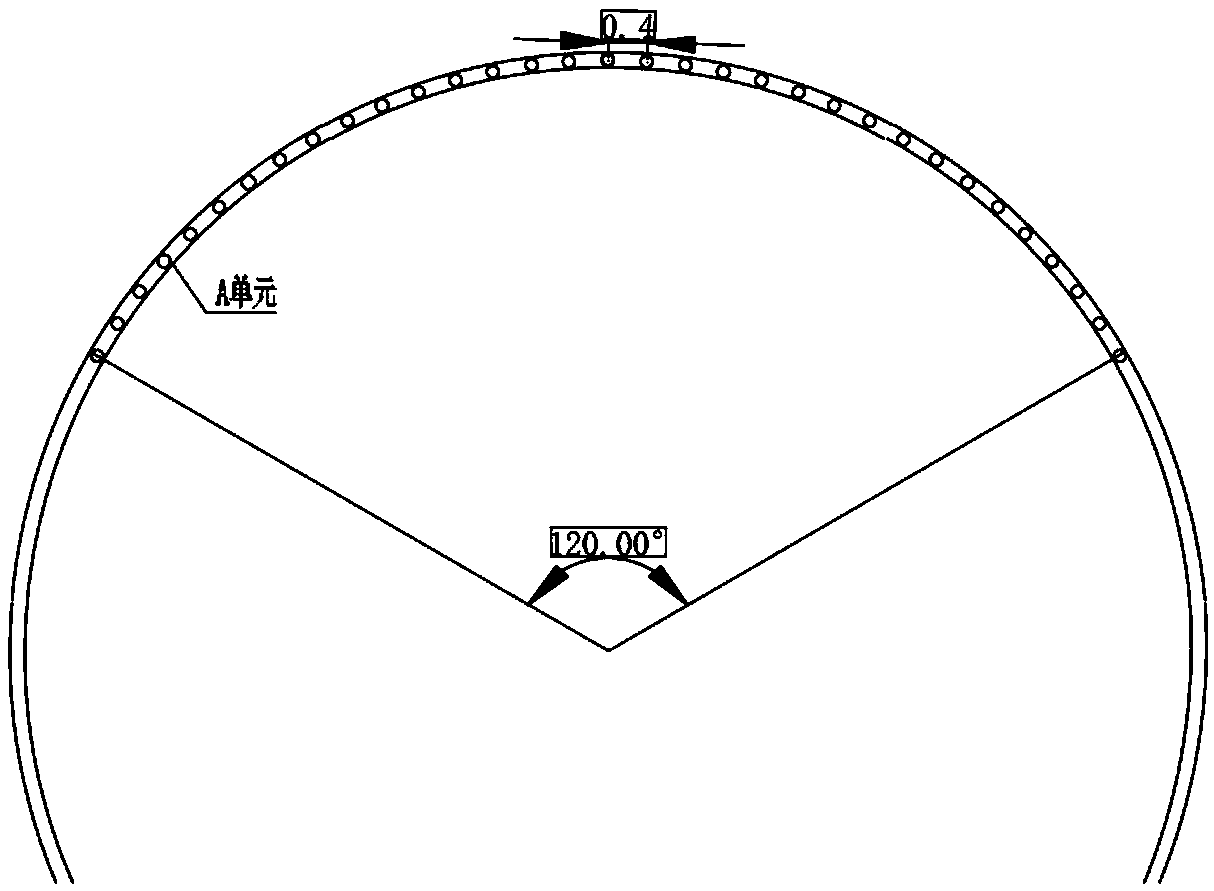

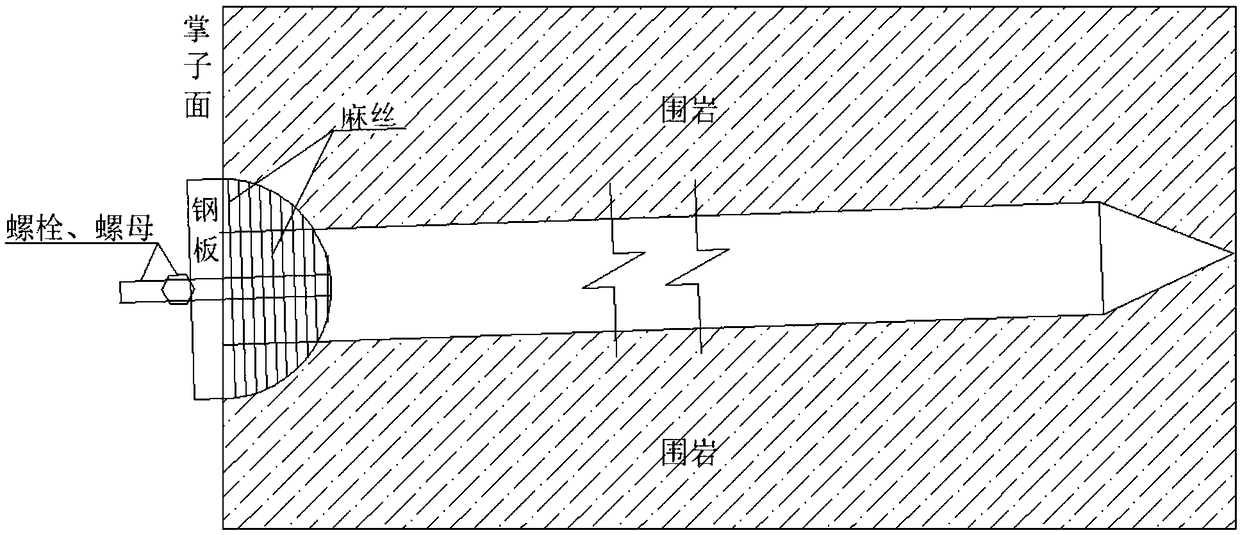

[0040] S2. The construction of the small conduit in advance, the length of the small conduit in advance is 4m, the circumferential direction is 35cm, the drilling angle is controlled at 6-10°, and the drilling range is within 120° of the center line of the tunnel. The air surface provides space for the three-arm rock drilling rig to set self-propelled bolts;

[0041] S3. The face of the face is closed; the face of the face is closed in two steps: the first step is to spray a layer of cement s...

Embodiment 2

[0064] see Figure 1-3 , in the embodiment of the present invention, a kind of bolt construction technology that guarantees safety, quality comprises the following steps:

[0065] S1. Pre-construction preparations, including construction measurement and grout configuration, in which the surveyors must accurately determine and record the drilling hole position; the grout configuration is 10min solidification, 15min solidification, and 20min solidification double-fluid slurry ratio, according to the actual grouting situation , for slurry selection;

[0066] S2. The construction of the small conduit in advance. The length of the small conduit in advance is 5m, and the circumferential direction is 40cm. Provide space for the three-arm rock drilling rig to set self-propelled bolts;

[0067] S3. The face of the face is closed; the face of the face is closed in two steps: the first step is to spray a layer of cement slurry within the vertical 50cm range of the anchor bolt, and then...

Embodiment 3

[0090] see Figure 1-3 , a bolt construction process that ensures safety and quality, S1, pre-construction preparations, including construction measurement, grout configuration, wherein surveyors must accurately determine the drilling hole position and record; grout configurations are 10min solidification, 15min solidification, 20min solidified double liquid slurry ratio, according to the actual grouting situation, the slurry selection;

[0091] S2. The construction of the small conduit in advance. The length of the small conduit in advance is 6m, and the circumferential direction is 45cm. , to provide space for the three-arm rock drilling rig to set self-propelled bolts;

[0092] S3. The face of the face is closed; the face of the face is closed in two steps: the first step is to spray a layer of cement slurry within the vertical range of 53cm of the anchor rod, and then spray 12cm of C25 spray coagulant on the entire face of the face , form a 1:0.2 slope after plain sprayi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com