Composite test specimen for all-dimensional direct observation of metal material penetration fusion welding micropores

A technology for deep penetration welding and metal test piece, which is applied in the field of composite test pieces for direct observation of metal material deep penetration welding small holes in all directions, and can solve the problem of no metal material deep penetration welding small hole composite test piece and no plasma distribution device. and methods to achieve high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

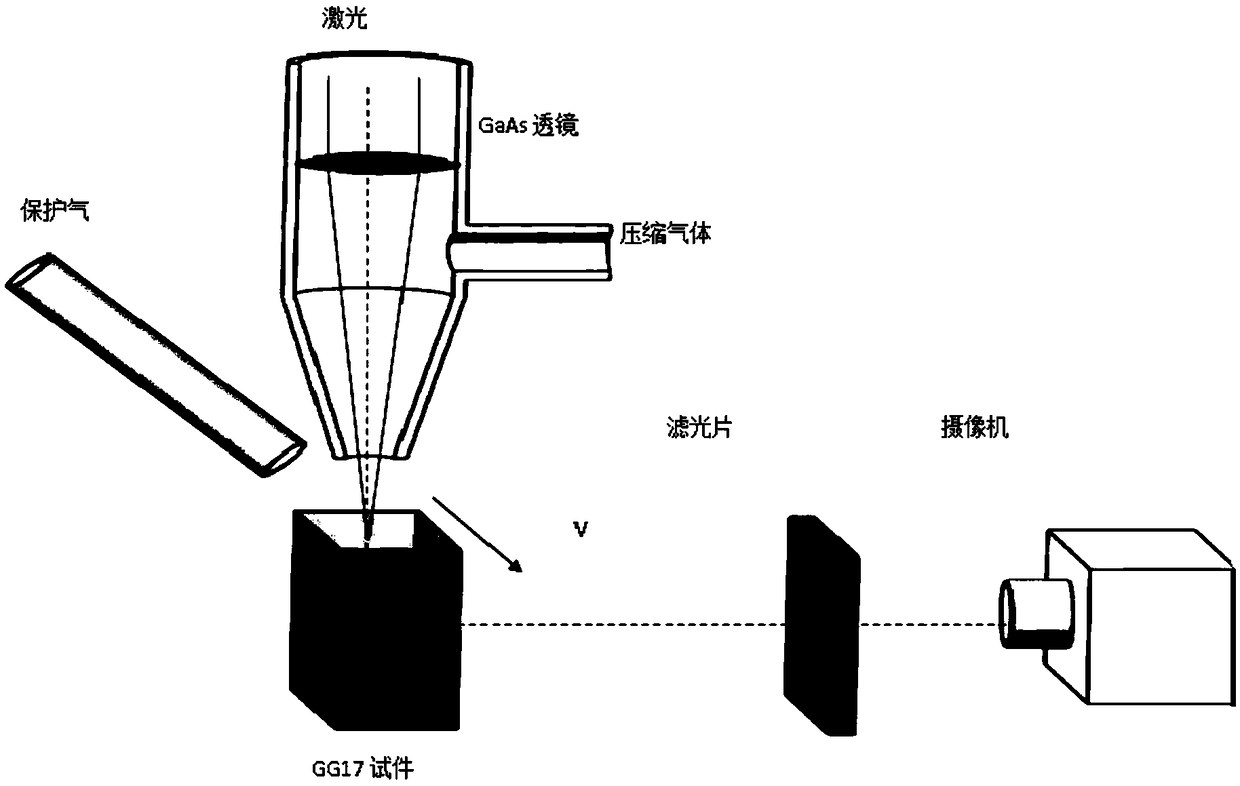

[0053] use as Image 6 The device shown is a technical solution for directly observing the cross-sectional contour shape of small holes at different depths in layers.

[0054] Such as Image 6 As shown, a new device for direct observation of small hole morphology in deep penetration welding (laser, electron beam, etc.) of metal materials, including mainly laser beam 1, compressed air inlet 2, laser welding nozzle 3, argon gas nozzle 11 , a laser welding head composed of GaAs focusing lens 12, a composite specimen composed of metal specimen 4 and GG17 specimen 5, and an image capturing component composed of optical filter 6, camera 7 and mirror 8.

[0055] Image 6The experimental principle of middle observation: the present invention adopts double-layer composite workpiece, that is, the upper metal test piece 4 is a metal widely used in engineering practice, and the lower part GG17 test piece 5 is transparent, special glass GG17 with good thermal shock resistance, The combi...

Embodiment 2

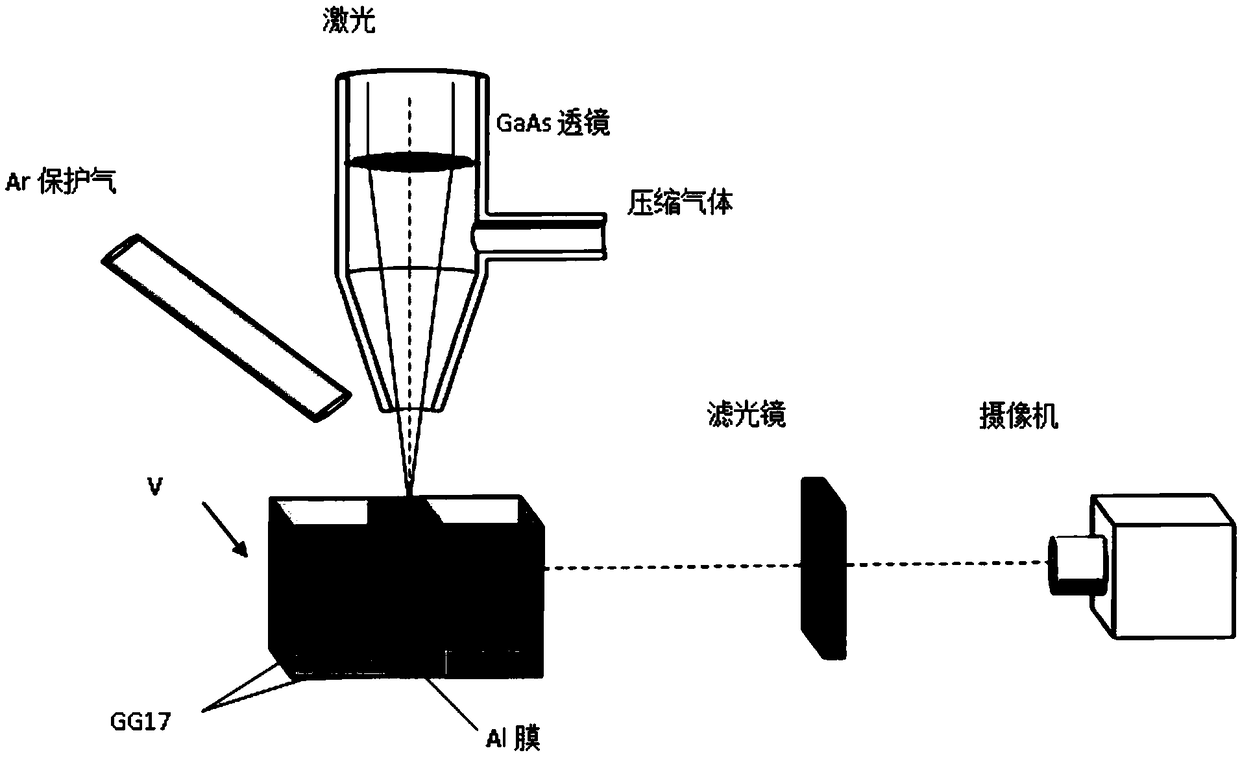

[0060] use as Figure 7 The device shown is a technical scheme for directly observing plasma information in the cross-section of small holes at different depths in layers.

[0061] Such as Figure 7 As shown, a new device for direct observation of plasma in small holes for deep penetration welding (laser, electron beam, etc.) of metal materials, including laser beam 1, compressed air inlet 2, laser welding nozzle 3, argon gas nozzle 11. The laser welding head composed of GaAs focusing lens 12, the composite specimen composed of metal specimen 4 and GG17 specimen 5, and the plasma spectrum signal composed of reflector 8, optical fiber fixing plate 13, optical fiber 14 and spectrometer 15 Detect parts.

[0062] Figure 7 Experimental principle of middle observation: the present invention adopts double-layer composite workpiece, that is, the metal test piece 4 of the upper part is a metal widely used in engineering practice, and the GG17 test piece 5 of the lower part is trans...

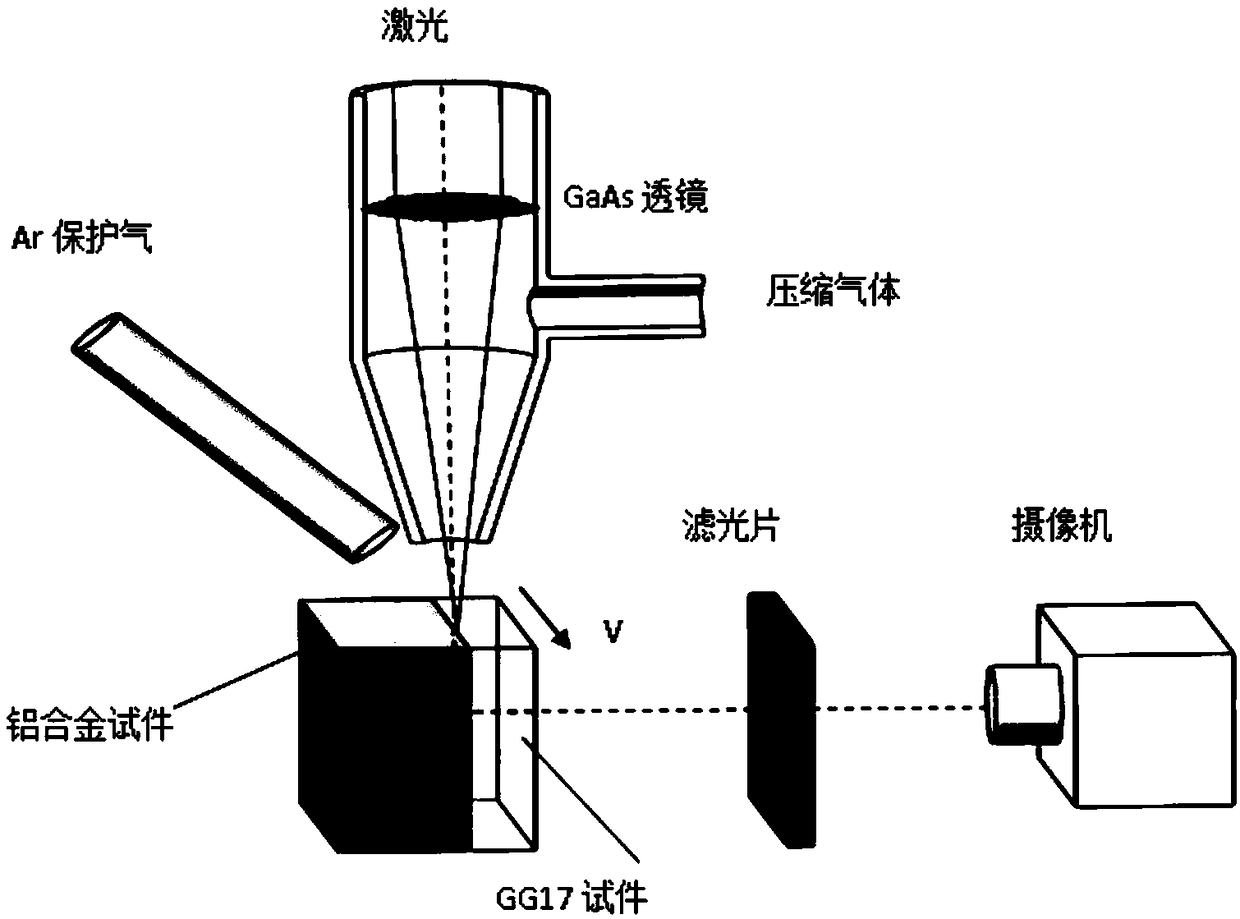

Embodiment 3

[0065] Figure 8 It is a structural schematic diagram of the composite test piece in the present invention that has formed the small hole 9 in the deep penetration welding process. Before deep penetration welding, the composite test piece described in the present invention does not contain pinholes. The composite test piece includes the metal test piece 4 on the top and the GG17 test piece 5 below, and the top surface of the whole composite test piece, that is, the top surface of the metal test piece, is a plane, and the bottom surface of the metal test piece is the same as the top surface of the GG17 test piece. The surfaces are all smooth joint surfaces, and the joint surface (88) of the metal test piece and the GG17 test piece and the top surface of the composite test piece form an angle of n degrees, and 0°<n<90°.

[0066] When preparing the composite test piece of the present invention (its structure sees for example Figure 8 ) process, the joint surfaces of the metal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com