Gas sensor characteristic test system for multi-physical field coupling environment

A gas sensor and multi-physics technology, applied in the direction of material resistance, can solve the problems of increased resistance, reduced carrier number, and increased carrier drift path, achieving high uniformity, controllable direction, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

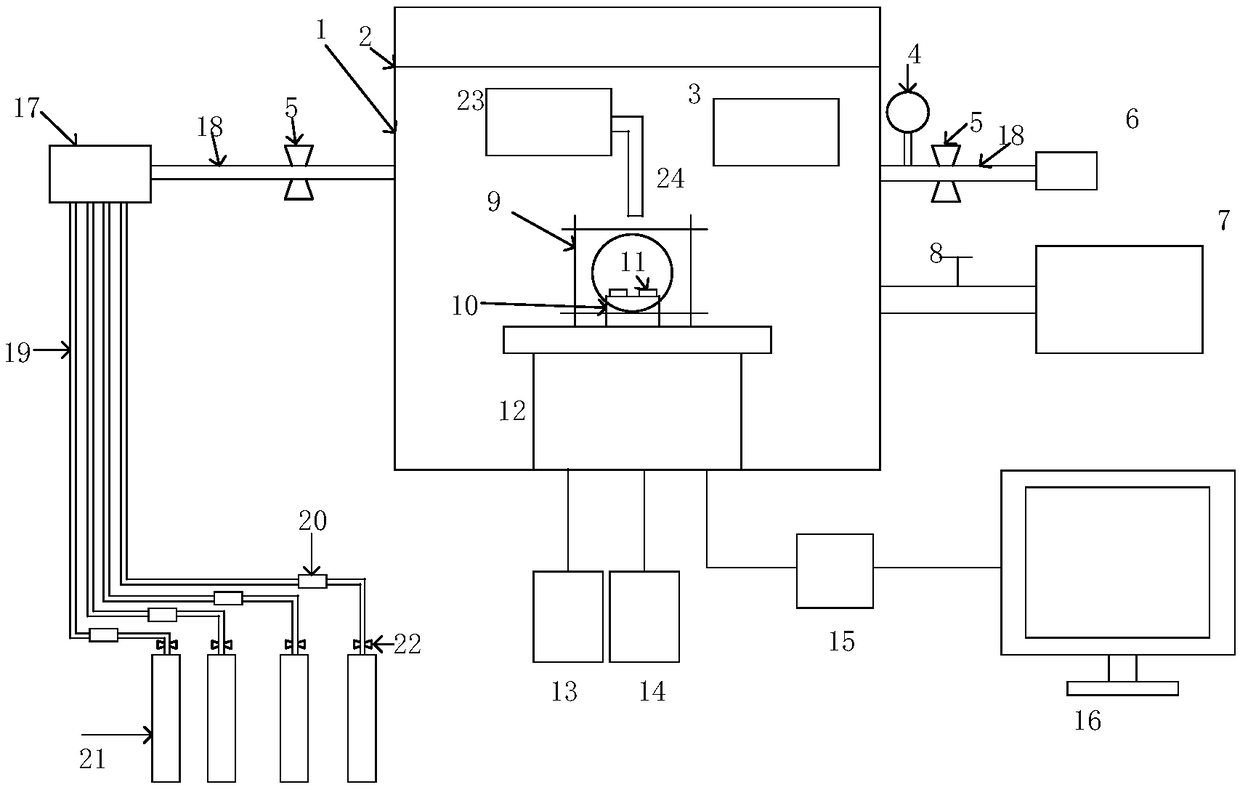

Embodiment 1

[0033] (1) Experiment preparation

[0034] Install the gas sensor at the gas sensor placement interface 11. Its output signal is led out to the data collector 15 outside through wires, and the output terminal of the data collector 15 is connected with the signal input terminal of the computer 16 . After the installation is completed, the test cavity is sealed by the sealing cover 2 to form a closed space. The test cavity is made of stainless steel, which can meet the pressure conditions during the experiment and the corrosiveness of the gas to be measured. Vacuuming is carried out afterwards, and the specific operation is to close the shut-off valve 5 of the gas passage 18 of the intake part. Turn on the vacuum pump 6 to vacuumize the test chamber 1.

[0035] (2) Experiment

[0036] According to the concentration requirements of the measured gas, the pressure reducing valve 22 and the cut-off valve 5 of the intake passage 19 are opened, and the voltage of the mass flow mete...

Embodiment 2

[0040] The experimental preparation is the same as that in the first embodiment, and the humidity is used as the changing condition in the part of performing the experiment. By controlling the humidity controller 7, the humidity in the test chamber 1 is changed, and the experimental data is recorded.

Embodiment 3

[0042] The experimental preparation is the same as that in Example 1, and in the part of performing the experiment, light is used as the changing condition. The light intensity in the chamber is changed by controlling the light source controller 23, and the experimental data is recorded.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com