High-performance sliding device for large-tonnage jacking projects

A sliding device, large tonnage technology, used in the erection/assembly of bridges, bridges, buildings, etc., can solve the problems of low compressive strength, cracking of the support position of the bottom plate, reducing the bearing capacity of the foundation, etc., to achieve a similar dynamic and static friction coefficient, direction Easy to control and improve the effect of carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

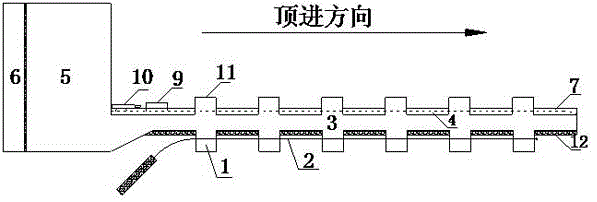

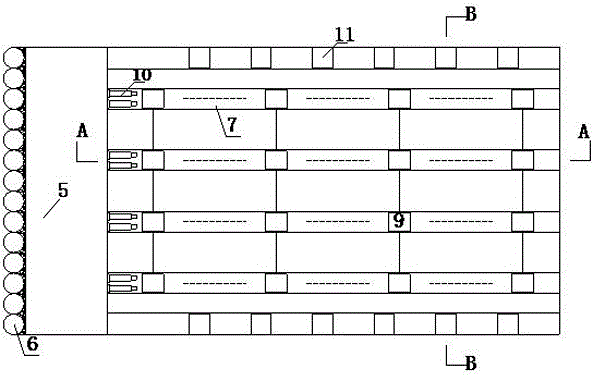

[0031] The high-performance sliding device for large-tonnage pushing projects involved in the present invention includes a ground anchor unit, a slide plate unit, a back unit, a horizontal sliding unit and a horizontal deviation correction unit.

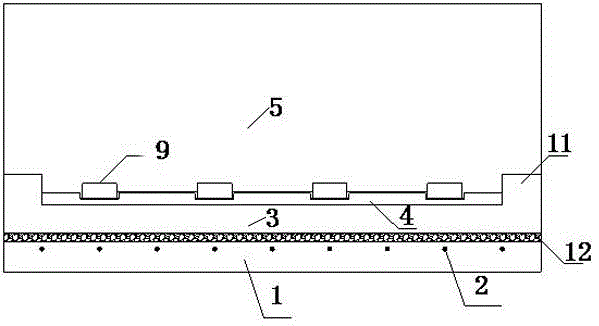

[0032] The slide unit is arranged on the ground anchor unit. There are several horizontal sliding units, all of which are arranged on the slide plate unit. The horizontal deviation correction unit is arranged on both sides of the slide unit.

[0033] The ground anchor unit includes a gravel layer 12 , a ground anchor beam 1 and several anchor cables 2 . The ground anchor unit sets the bottom of the slide unit to prevent the slide from sliding forwar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com