Patterned quantum dot color film, preparation method thereof, and display device

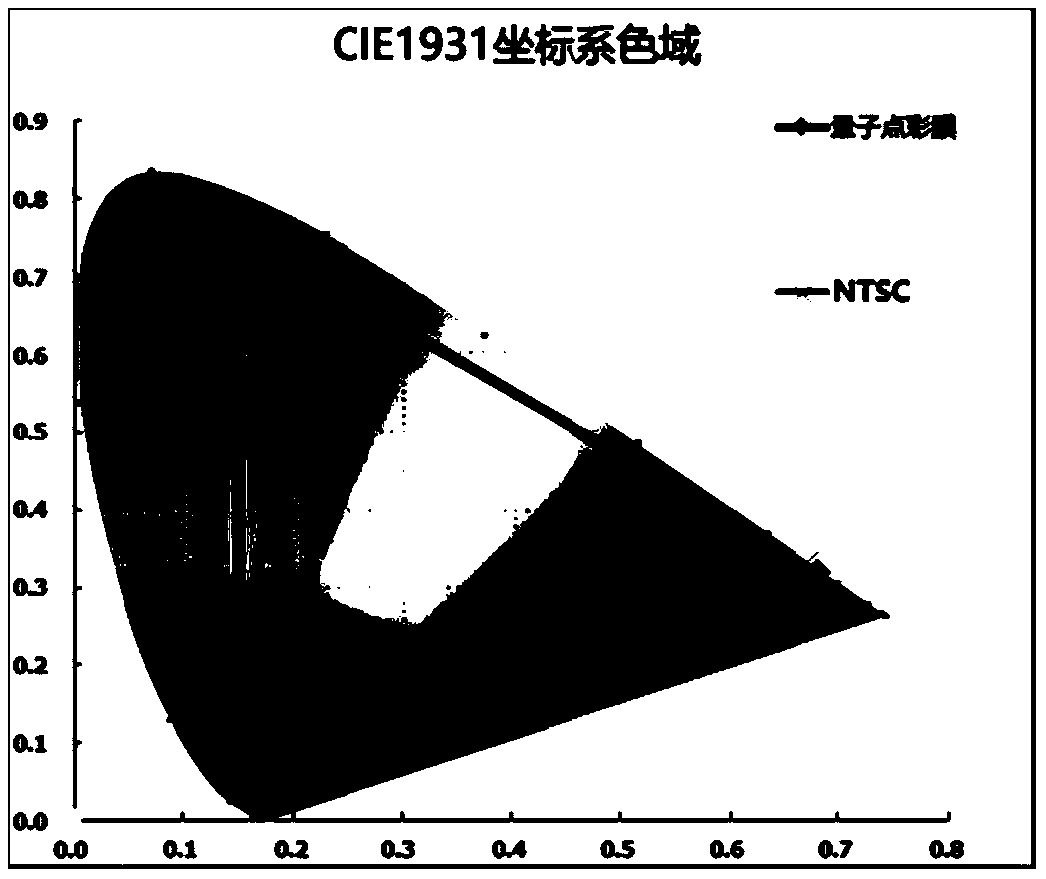

A quantum dot and patterning technology, which is applied to the exposure device of photoengraving process, photoengraving process of pattern surface, optical mechanical equipment, etc., can solve the problems of complex process, excitation of green quantum dot filter, etc. Pure, simple and efficient preparation method, the effect of improving brightness and color gamut

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

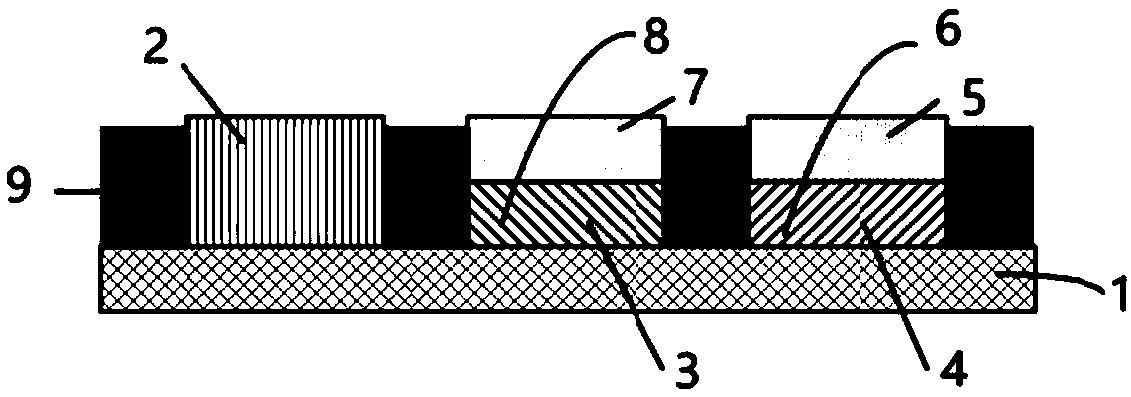

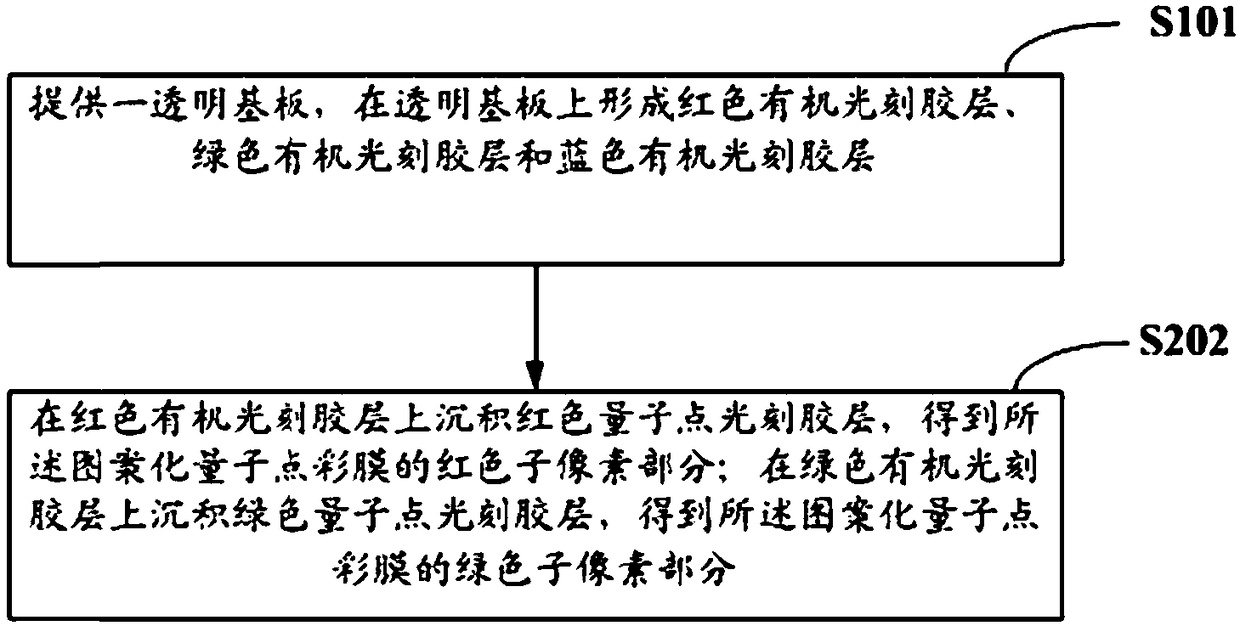

[0055] figure 2 The preparation method of the above-mentioned patterned quantum dot color film is provided, comprising the steps of:

[0056] S101: Provide a transparent substrate, and form a red organic photoresist layer, a green organic photoresist layer and a blue organic photoresist layer on the transparent substrate;

[0057] S102: Depositing a red quantum dot photoresist layer on the red organic photoresist layer to obtain the red sub-pixel part of the patterned quantum dot color film; depositing a green quantum dot photoresist layer on the green organic photoresist layer , to obtain the green sub-pixel part of the patterned quantum dot color film.

[0058] In S101 , a red organic photoresist layer, a green organic photoresist layer and a blue organic photoresist layer are formed on the transparent substrate by using an organic color photoresist material through a photolithography process.

[0059] In the preparation method of the present invention, by coating the qua...

Embodiment 1

[0080] Provide a transparent substrate through photolithography, and form a black matrix on the transparent substrate through a photolithography process to separate the red sub-pixel part, the green sub-pixel part and the blue sub-pixel part;

[0081] Through a photolithography process, a red organic photoresist layer, a green organic photoresist layer and a blue organic photoresist layer are formed on a transparent substrate formed with a black matrix; wherein, the red organic photoresist layer, the green organic photoresist layer The thickness of the resist layer is 1 μm, and the thickness of the blue organic photoresist layer is 6 μm;

[0082] Deposit a red quantum dot photoresist layer on the red organic photoresist layer through a photolithography process to obtain the red sub-pixel part of the patterned quantum dot color film; through a photolithography process, deposit a green photoresist layer on a green organic photoresist layer The quantum dot photoresist layer is us...

Embodiment 2

[0084] Deposit a red quantum dot photoresist layer on a red organic photoresist layer by an inkjet printing process, and deposit a green quantum dot photoresist layer on a green organic photoresist layer by an inkjet printing process, and others are the same as in Example 1 same.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com