Current monitoring and reforming device for heating pipe of annealing furnace

A current monitoring and heating tube technology, which is applied in the direction of electrical program control, heat treatment process control, furnace, etc., can solve the problems of lack of heating tube monitoring means and failure to find faults in time, so as to prevent batch quality accidents, realize automatic monitoring management, fast response effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

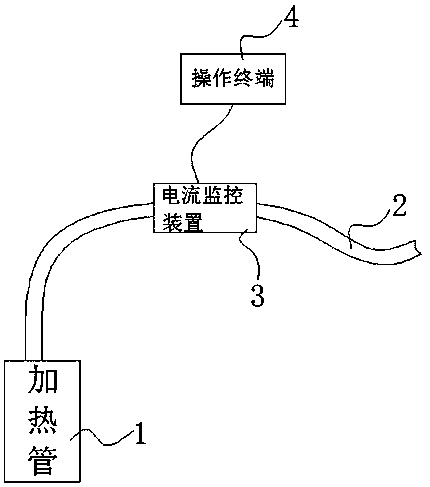

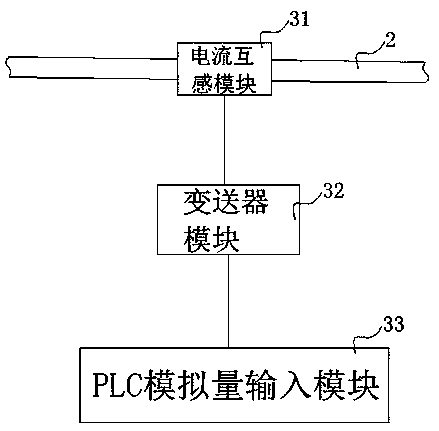

[0028] Such as Figure 1-Figure 2 As shown, the current monitoring reformation device of the annealing furnace heating tube of the present invention includes a heating tube 1 installed at the bottom of the annealing furnace, and the heating tube 1 is connected to a power supply cable 2, and the heating tube 1 here heats up the annealing furnace. The innovation of the present invention is that a current monitoring device 3 is installed on the power supply cable 2, and the current monitoring device 3 is composed of a current mutual induction module 31, a transmitter module 32 and a PLC analog input module 33. The input terminal of the mutual induction module 31 is electrically connected with the power supply cable 2, the output terminal of the current mutual induction module 31 is connected with the input terminal of the transmitter module 32, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com