Double wrap spring, rotation device and system to be actuated

A rotary device, dual technology, applied in the field of dual wrap springs, can solve the problem of late entry into expectations, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] To illustrate the conventional double wrap spring has been referred to Figures 1 to 5 .

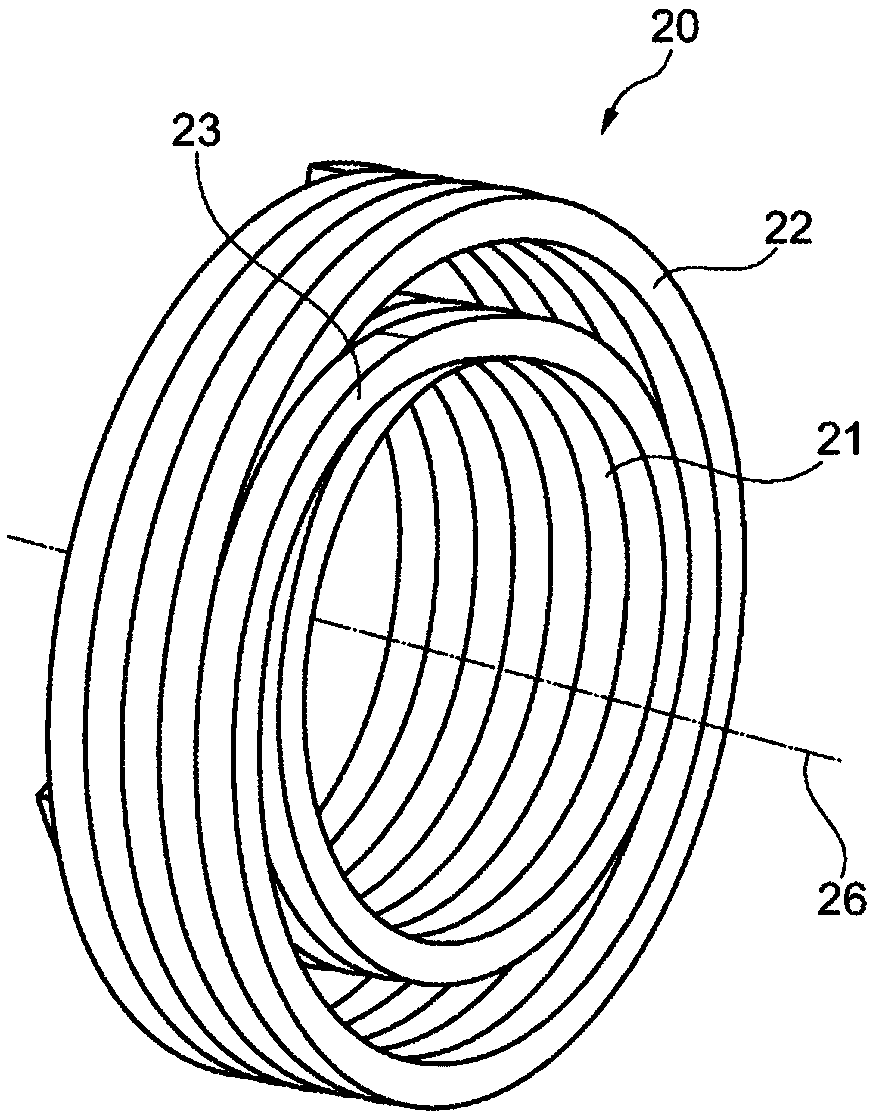

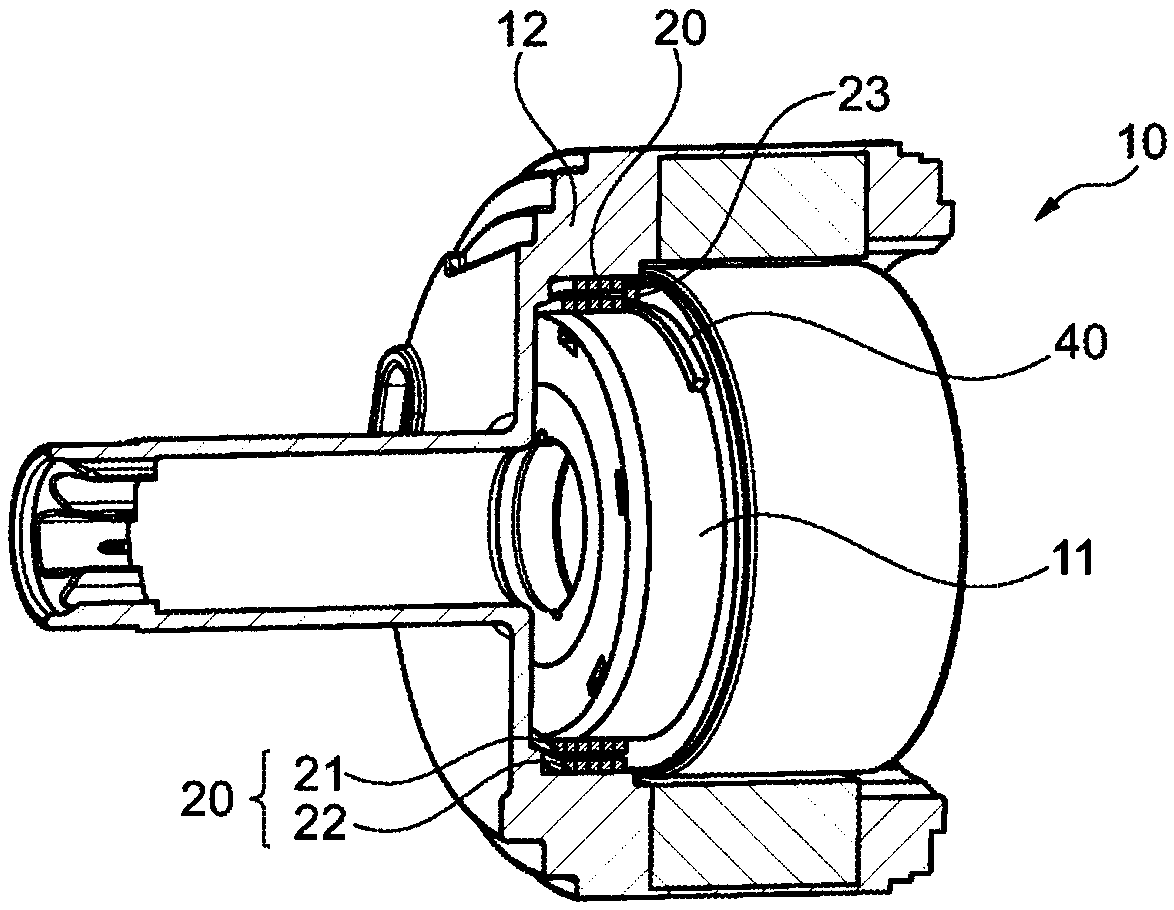

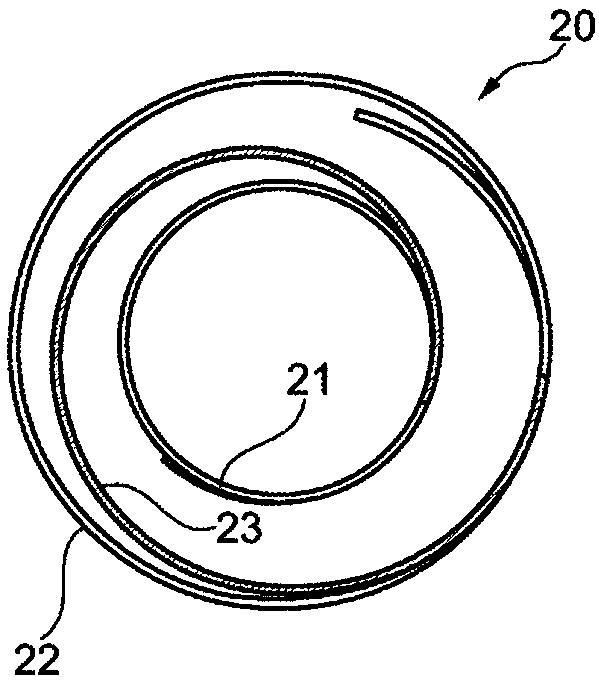

[0055] exist Figures 6 to 9 It can be seen in the uninstalled state ( Image 6 with 8 ) and installed state ( Figure 7 with 9 ) according to two different designs of the double wrap spring of the present invention. as in Image 6 As shown in , the double wrap spring of the embodiment shown here has an inner wrapping region 21 and an outer wrapping region 22 which, due to the eccentricity of the wrapping regions 21, 22, are in the same direction as the wrapping region In the region of the transition between 21 , 22 there is an extremely small distance a from one another. The transition region 23 between the inner wrapping region 21 and the outer wrapping region 22 is designed here to be extremely short and has a correspondingly small radius of curvature Rk. Figure 7 This embodiment of the double wrap spring is shown in the installed state, in which it can be seen that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com