Whipped custard cream and preparation method thereof

A cream sauce and selected technology, applied in the field of custard cream sauce and its preparation, can solve the problems of inability to meet the application requirements of modern industrialized bakery products, oil separation, aging and hardening, and poor water retention, etc., and achieve easy freezing. Storage and transportation, good freeze-thaw stability, fine and smooth taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

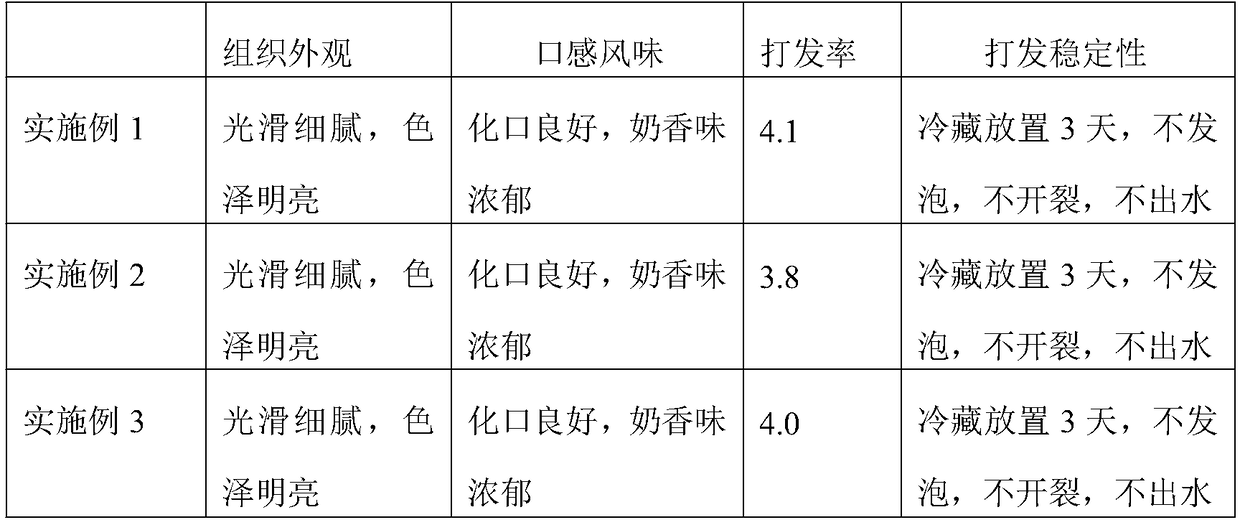

Examples

Embodiment 1

[0026] In this implementation of custard cream sauce, the formula used for each raw material is: water: 53%, hydrogenated palm kernel oil: 14%, sugar: 18%, skimmed milk powder: 5%, sweet whey powder: 5%, egg yolk powder 0.88%, Hydroxypropyl Distarch Phosphate: 2%, Xanthan Gum: 0.3%, Locust Bean Gum 0.2%, Monoglyceride: 1%, Sorbitol: 0.5%, Table Salt: 0.01%, Phosphate: 0.01 %, pigment essence: 0.1%;

[0027] The preparation process is as follows:

[0028] (1) Preparation of oil phase: disperse the emulsifier and edible gum in the above parts by weight in edible oil to prepare oil phase mixture 1;

[0029] (2) Water phase preparation: water phase preparation: adding the above-mentioned syrup, modified starch, white granulated sugar, milk powder, protein, and whey powder into water, and stirring evenly to obtain the water phase mixture 2;

[0030] (3) Mix the water phase and the oil phase and stir evenly to obtain a mixture 3, and control the temperature of the mixture 3 to be ...

Embodiment 2

[0036] In this implementation of custard cream sauce, the formula used for each raw material is: water: 50%, hydrogenated palm kernel oil: 15%, white sugar: 19.86%, whey protein 2%, whole milk powder 3%, egg liquid 2 %, modified starch 3%, microcrystalline cellulose 0.5%, gelatin 0.5%, monoglyceride 0.5%, emulsified starch: 2%, sorbitol: 1.5%, salt: 0.02%, phosphate: 0.02%, color essence : 0.1%;

[0037] The preparation process is as follows:

[0038] (1) Preparation of oil phase: disperse the emulsifier and edible gum in the above parts by weight in edible oil to prepare oil phase mixture 1;

[0039] (2) Water phase preparation: water phase preparation: adding the above-mentioned syrup, modified starch, white granulated sugar, milk powder, protein, and whey powder into water, and stirring evenly to obtain the water phase mixture 2;

[0040] (3) Mix the water phase and the oil phase and stir evenly to obtain a mixture 3, and control the temperature of the mixture 3 to be low...

Embodiment 3

[0046] In this implementation of custard cream sauce, the formula composition of each raw material is: water: 43.9%, hydrogenated palm kernel oil: 20%, glucose: 25%, whole milk powder: 5%, egg yolk powder: 2%, modified starch: 2%, Locust Bean Gum: 0.2%, Guar Gum 0.2%, Monoglyceride: 1%, Sorbitol: 0.5%, Salt: 0.05%, Phosphate: 0.05%, Color Flavor: 0.1%;

[0047] The preparation process is as follows:

[0048] (1) Preparation of oil phase: disperse the emulsifier and edible gum in the above parts by weight in edible oil to prepare oil phase mixture 1;

[0049] (2) Water phase preparation: water phase preparation: adding the above-mentioned syrup, modified starch, white granulated sugar, milk powder, protein, and whey powder into water, and stirring evenly to obtain the water phase mixture 2;

[0050] (3) Mix the water phase and the oil phase and stir evenly to obtain a mixture 3, and control the temperature of the mixture 3 to be lower than 45° C.;

[0051] (4) Homogenization:...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com