A 3D embossing device for diapers

A diaper, 3D technology, applied in the field of diapers, can solve the problem of uncomfortable wearing in the contact area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] By the description of the examples, the specific embodiments of the present invention, such as the interaction between the shape, configuration, each portion of each member, and the respective portions, manufacturing processes, and operation methods of various parts. Wait a further detailed description to help those skilled in the art will have more complete, accurate and in-depth understanding of the present invention.

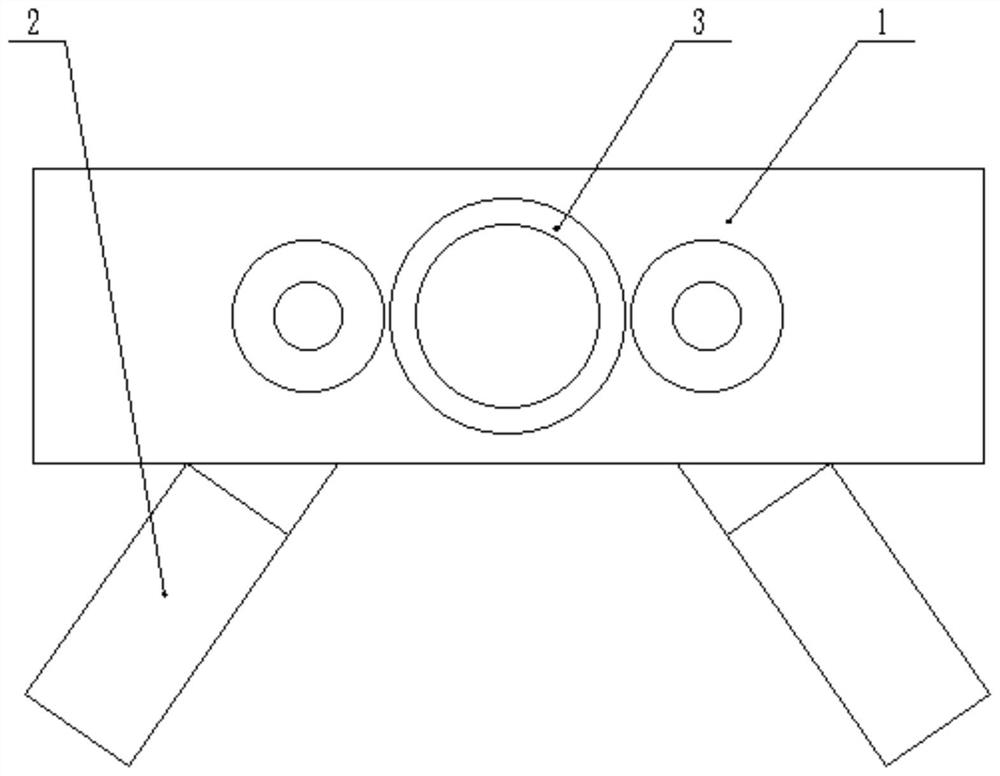

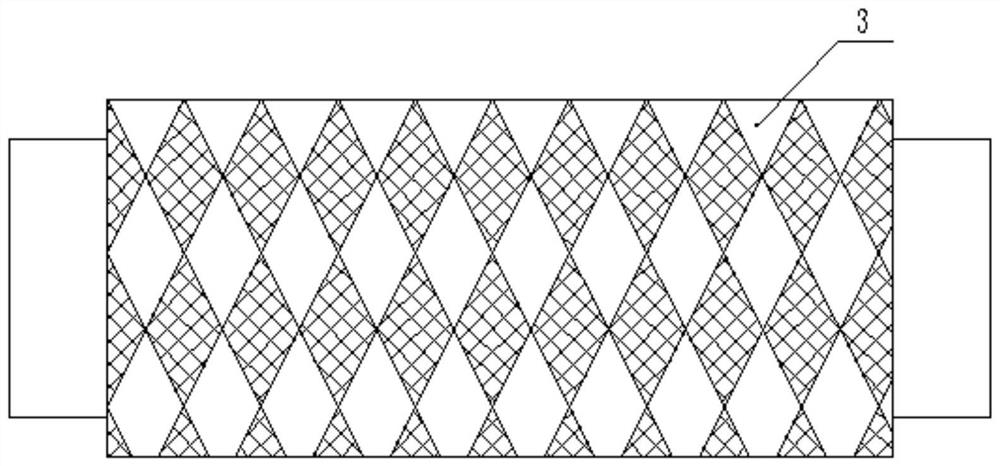

[0012] The present invention provides a diaper 3D embossing apparatus including the main pressure roller 1, and two drive motor 2 disposed on the main pressure roller 1, the roller 3 in the main pressure roller 1, The roller motor for driving the roller 3 is provided on the roller 3, and the two active rollers and a plurality of pieces disposed on the roller 3 are respectively disposed on the roller 1, respectively. Two drive motor 2 drives two active rolls, respectively. The output shaft of the roller motor is connected to the roller 3, and the body of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com