Automatic sewage and waste impurity treatment equipment

An automatic processing and impurity technology, applied in grain processing, solid waste removal, magnetic separation, etc., can solve the problems of magnetic conductive material recycling, environmental damage, resource waste, etc., to achieve efficient recovery, high degree of automation, recycling good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

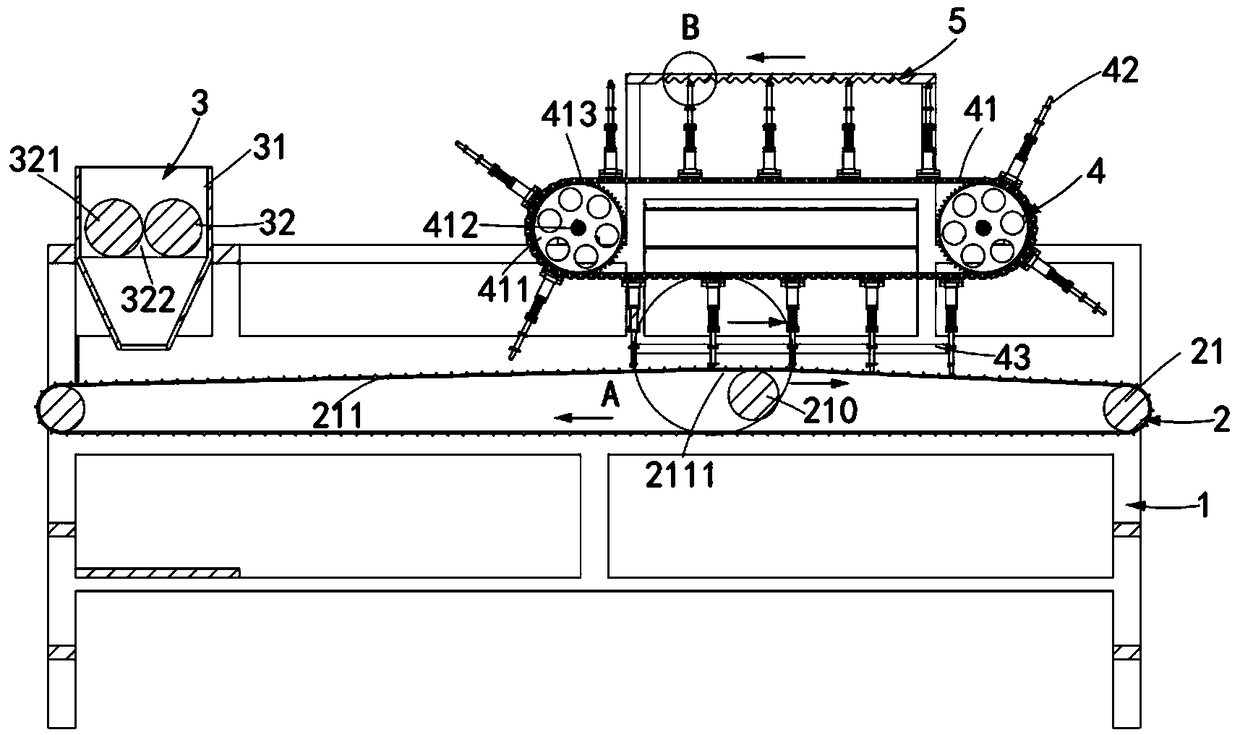

[0059] Such as figure 1 , figure 2 , image 3 , Figure 4 versus Figure 5 As shown, an automatic treatment equipment for waste and impurities includes a support 1, and further includes:

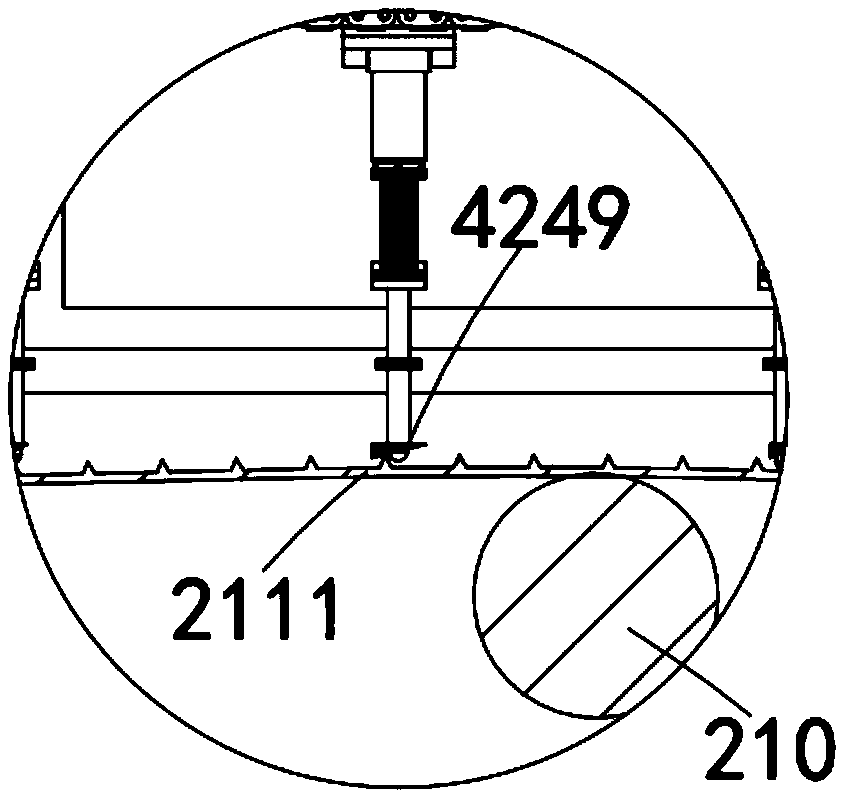

[0060] The transfer and conveying mechanism 2, which is arranged on the support 1 and includes a first conveying component 21 and a second conveying component 22 that are vertically staggered, and the first conveying component 21 is located on the first conveying component Below the second conveying assembly 22, the first conveying assembly 21 transfers and conveys impurities, and the second conveying assembly 22 conveys the magnetically permeable material recovered from the impurities. The first conveying assembly 21 includes a rotating arrangement along the support 1 The first conveyor belt 211, the middle part of the first conveyor belt 211 is convexly provided with a protrusion 2111;

[0061] A crushing mechanism 3, the crushing mechanism 3 is arranged above the feed end of the first conveyi...

Embodiment approach

[0082] Such as figure 1 As shown, as a preferred embodiment, the driving assembly 41 includes:

[0083] A drive sprocket 411, which is symmetrically arranged above the first conveying assembly 21, and is rotationally matched with the bracket 1 through a shaft 412;

[0084] A drive chain 413, the drive chain 413 and the drive sprocket 411 are configured to cooperate in transmission, and the magnetic attraction components 42 are equidistantly arranged along the drive chain 413; and

[0085] The drive motor 414 is arranged on one side of any one of the drive sprocket 411 and drives the drive sprocket 411 to rotate.

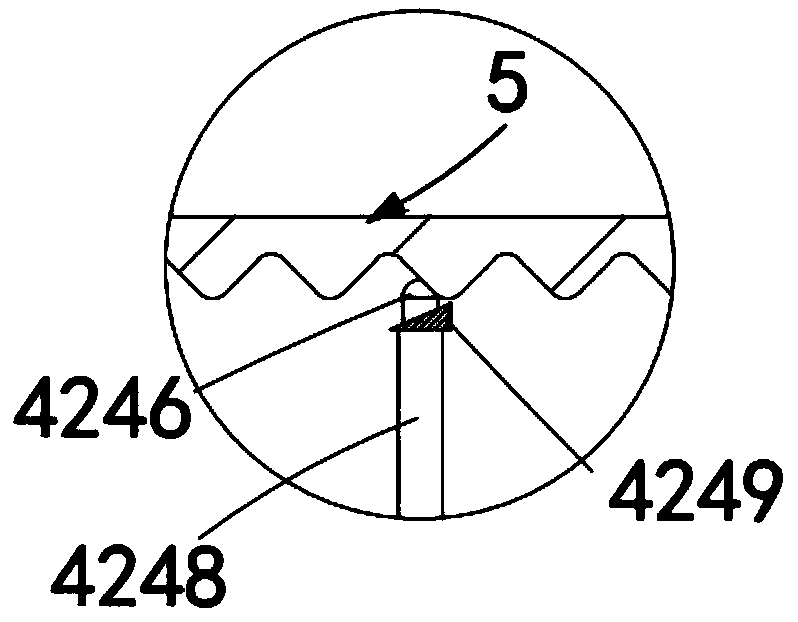

[0086] Such as figure 1 , figure 2 , image 3 , Figure 7 , Picture 8 versus Picture 9 As shown, as a preferred embodiment, the magnetic attraction component 42 includes:

[0087] A fixing seat 421, the fixing seat 421 is connected to the driving assembly 41, and is separately arranged on both sides of the first conveyor belt 211 in the width direction; and

[0088] The magn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com