Technology for controlling polymer crystallization degree in extrusion processing process

A processing and polymer technology, applied in the field of polymer crystallinity control, can solve the problems of instability and low performance, and achieve the effect of high yield, low cost, stable and uniform crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

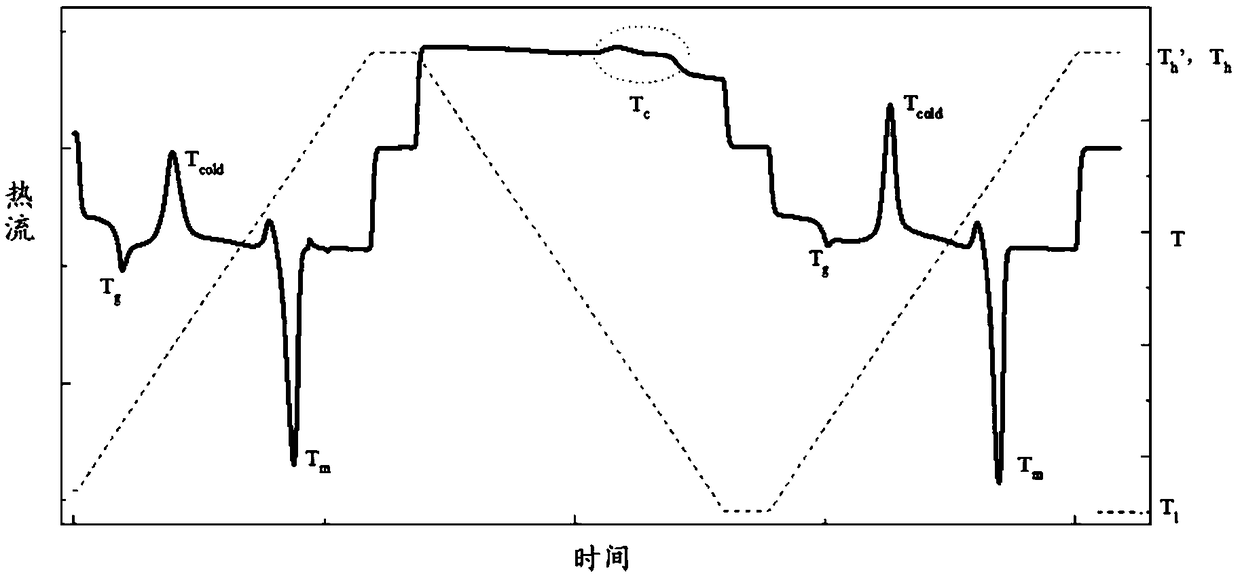

Embodiment 1

[0050] The L1001 brand polylactic acid material from Suzhou Jufu Polymer Material Co., Ltd. was selected for extrusion processing, and the relevant parameters of the material and its crystallization behavior were obtained by DSC measurement on Shimadzu's DSC-60Plus instrument. The specific measurement method is: use a high-precision balance to weigh 50 mg of the material to be tested, put it into an aluminum crucible, add an aluminum upper cover, press the sample and put it into the instrument. Set the heating and cooling program of the instrument as follows: firstly raise the temperature from room temperature to 230°C at a rate of 10°C / min, and keep it constant for 3 minutes; then cool down to 20°C at a rate of 10°C / min, and keep it constant for 3 minutes; The temperature was raised to 230° C., and the experiment ended. Heat flow data is extracted for the entire process and the associated temperature of the material is obtained from the curve peak data. The properties relate...

Embodiment 2

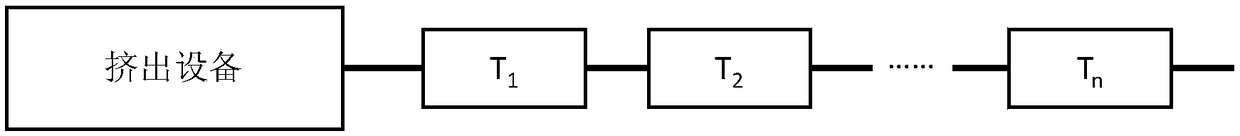

[0058] The L2001 brand polylactic acid material produced by Suzhou Jufu Polymer Materials Co., Ltd. was used for extrusion processing, and the detection method of Example 1 was used to obtain the relevant parameters of the material and its crystallization behavior through DSC measurement on the DSC-60Plus instrument of Shimadzu. Finally, the properties related to the material and crystallization behavior are as follows: T g =56.6°C; T c =124.2°C; T cold =93.2°C; T m = 168.6°C. It can be seen that the material has both melt crystallization and cold crystallization behaviors. In the traditional wire rod production process, the cooling rate of the melt is 50-100°C / s, and the quenching inhibits the regular arrangement of molecular chains, which greatly affects the melt crystallization behavior, and the crystallinity in the wire rod is low.

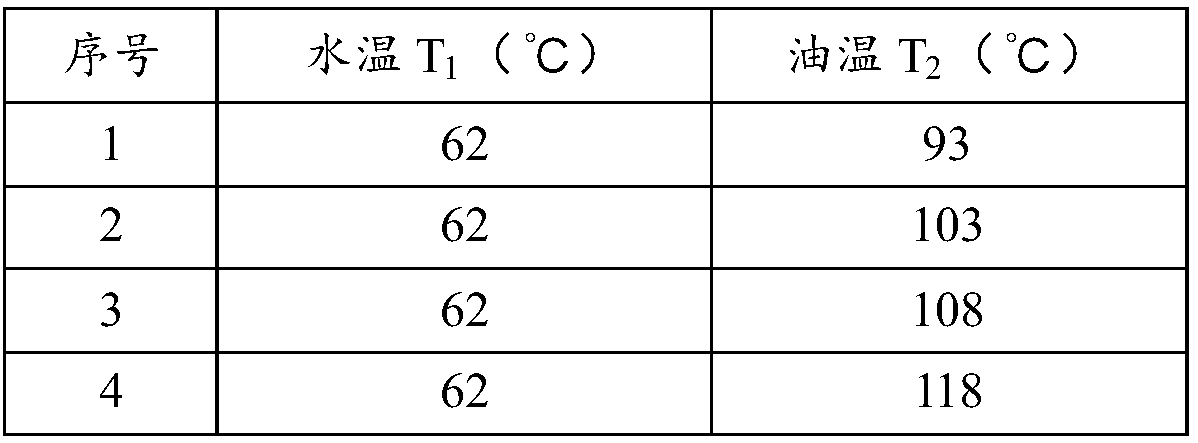

[0059]According to the fact that the material has melt crystallization and cold crystallization behaviors at the same time, this embodime...

Embodiment 3

[0063] The L2001 brand polylactic acid material produced by Suzhou Jufu Polymer Materials Co., Ltd. was used for extrusion processing, and the detection method of Example 1 was used to obtain the relevant parameters of the material and its crystallization behavior through DSC measurement on the DSC-60Plus instrument of Shimadzu. Finally, the properties related to the material and crystallization behavior are as follows: T g =56.6°C; T c =124.2°C; T cold =93.2°C; T m = 168.6°C. It can be seen that the material has both melt crystallization and cold crystallization behaviors. In the traditional wire rod production process, the cooling rate of the melt is 50-100°C / s, and the quenching inhibits the regular arrangement of molecular chains, which greatly affects the melt crystallization behavior, and the crystallinity in the wire rod is low.

[0064] According to the fact that the material has melt crystallization and cold crystallization behaviors at the same time, this embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com