Honeycomb sandwich board with embedded multi-level structure

A sandwich panel and multi-level technology, applied in the field of composite materials, can solve the problems of serious noise and vibration in the cabin, and achieve the effects of improving safety level, saving materials and stabilizing the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The description will be further elaborated below in conjunction with specific embodiments.

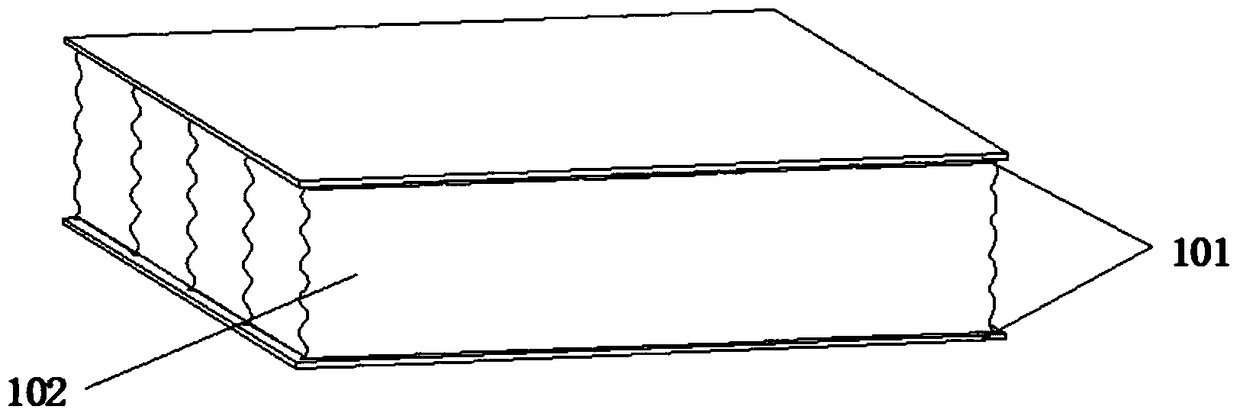

[0030] A kind of honeycomb sandwich panel embedded with multi-level structure provided by this embodiment, the overall schematic diagram is as follows figure 1 As shown, it consists of upper and lower panels 101 and a middle honeycomb core 102 .

[0031] Among them, the upper and lower panels 101 are made of carbon fiber plates, the tensile strength of which is several times that of ordinary steel, and has excellent creep resistance, corrosion resistance and shock resistance.

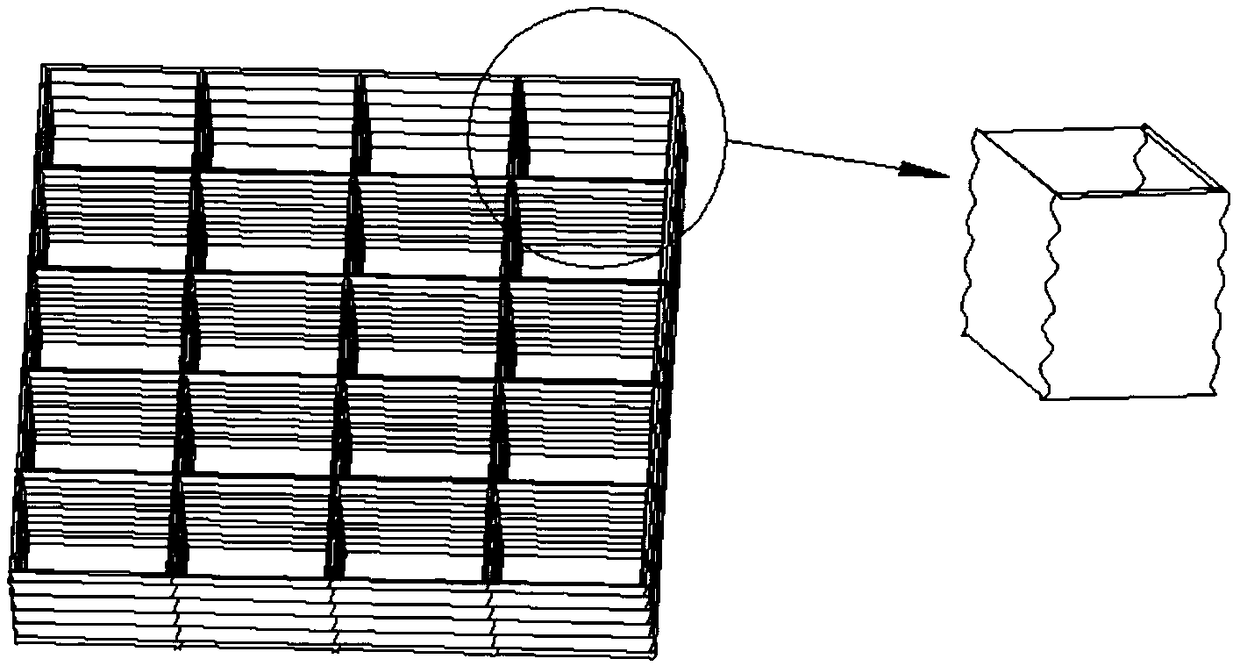

[0032] The honeycomb core structure 102 is made of aluminum alloy, which is obtained by combining multiple square bellows arrays, such as figure 2 As shown, the corrugation of the corrugated pipe is induced by a sinusoidal curve, which has a better effect of absorbing vibration than the traditional triangular cross-section corrugated pipe.

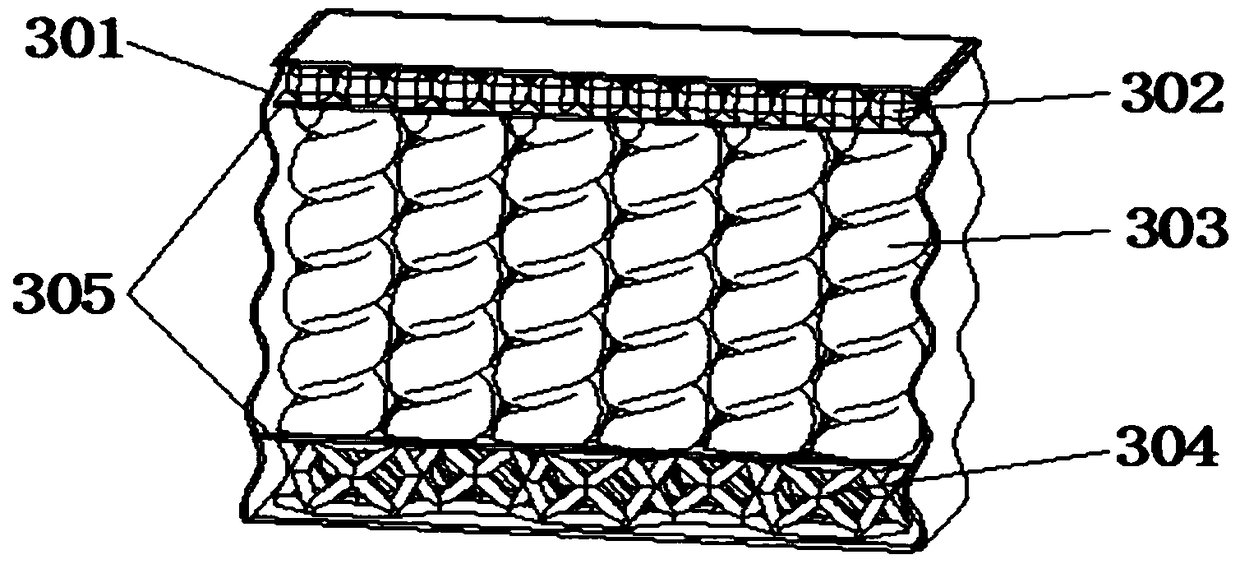

[0033] A hierarchical composite structure is embedded inside ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Sound absorption coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com