Aviation tray lifting and turnover device

A technology of turning device and pallet, which is applied in the direction of lifting device, lifting frame, transportation and packaging, etc., which can solve the problems of reducing production efficiency, pallet weight, and more labor, and achieve the effect of improving production efficiency and saving manpower

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

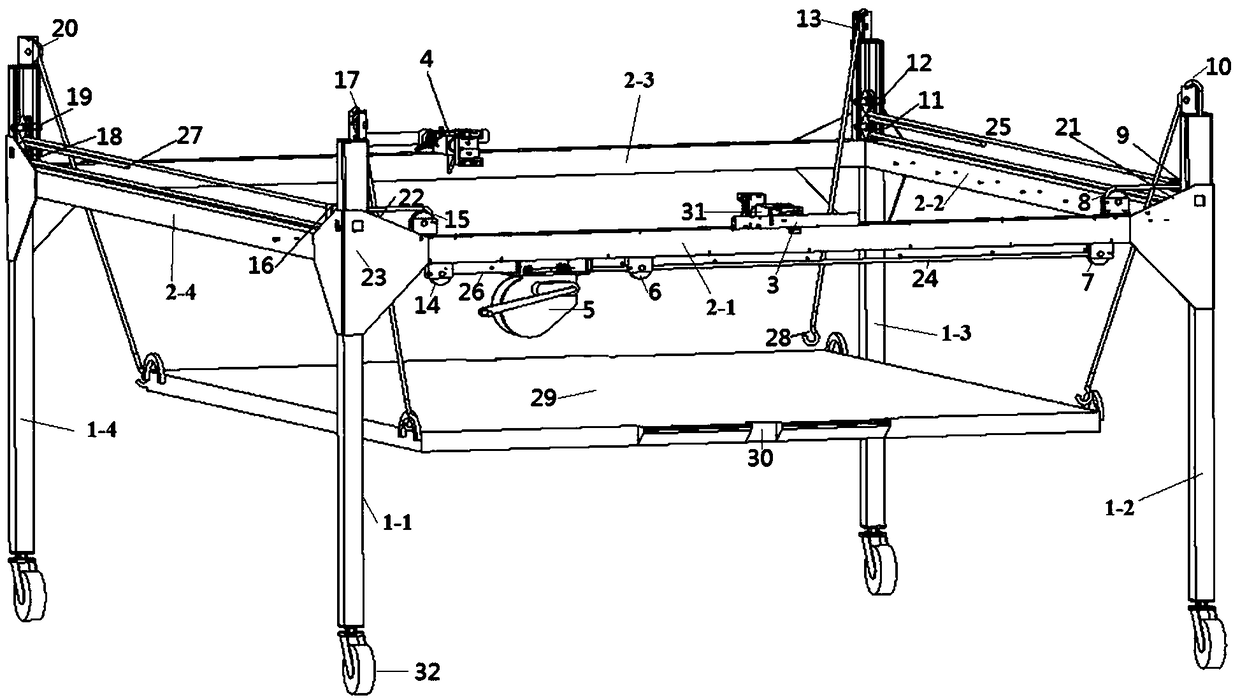

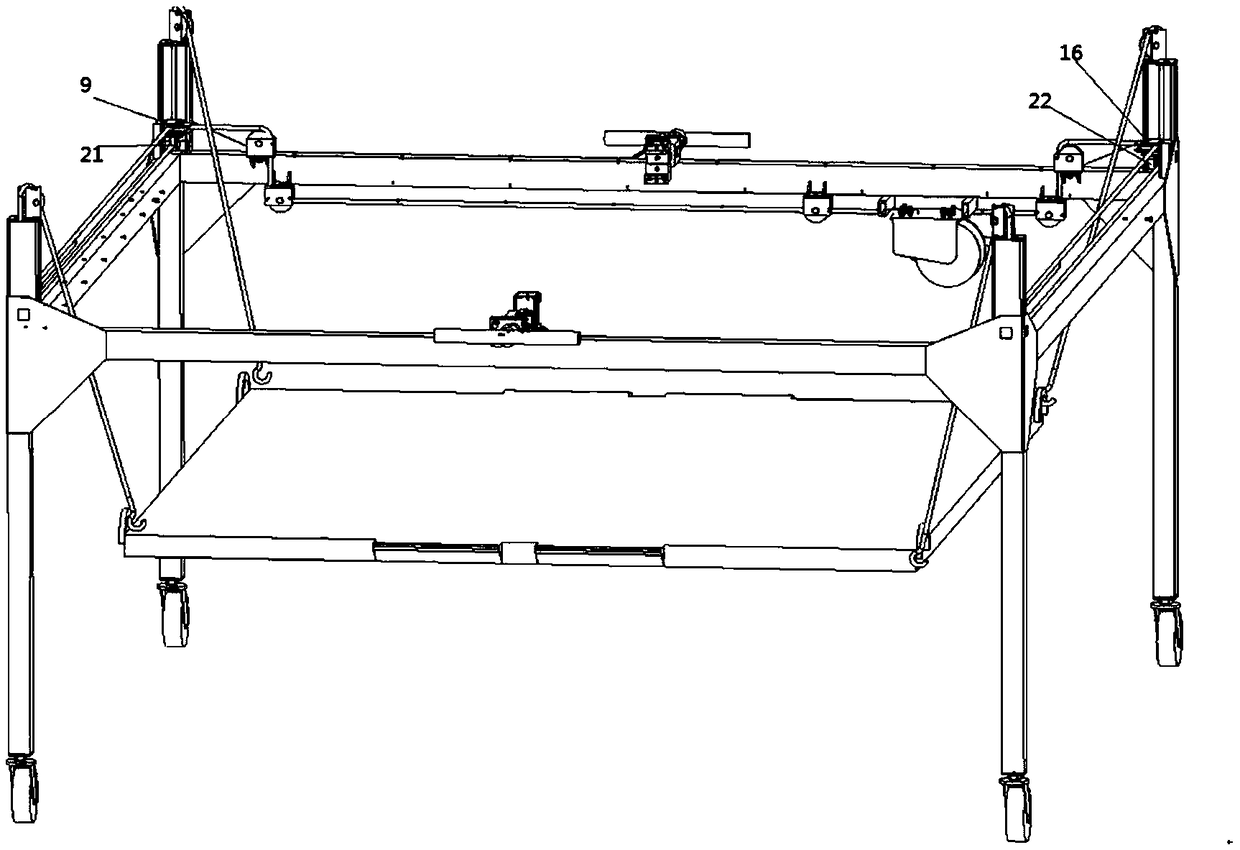

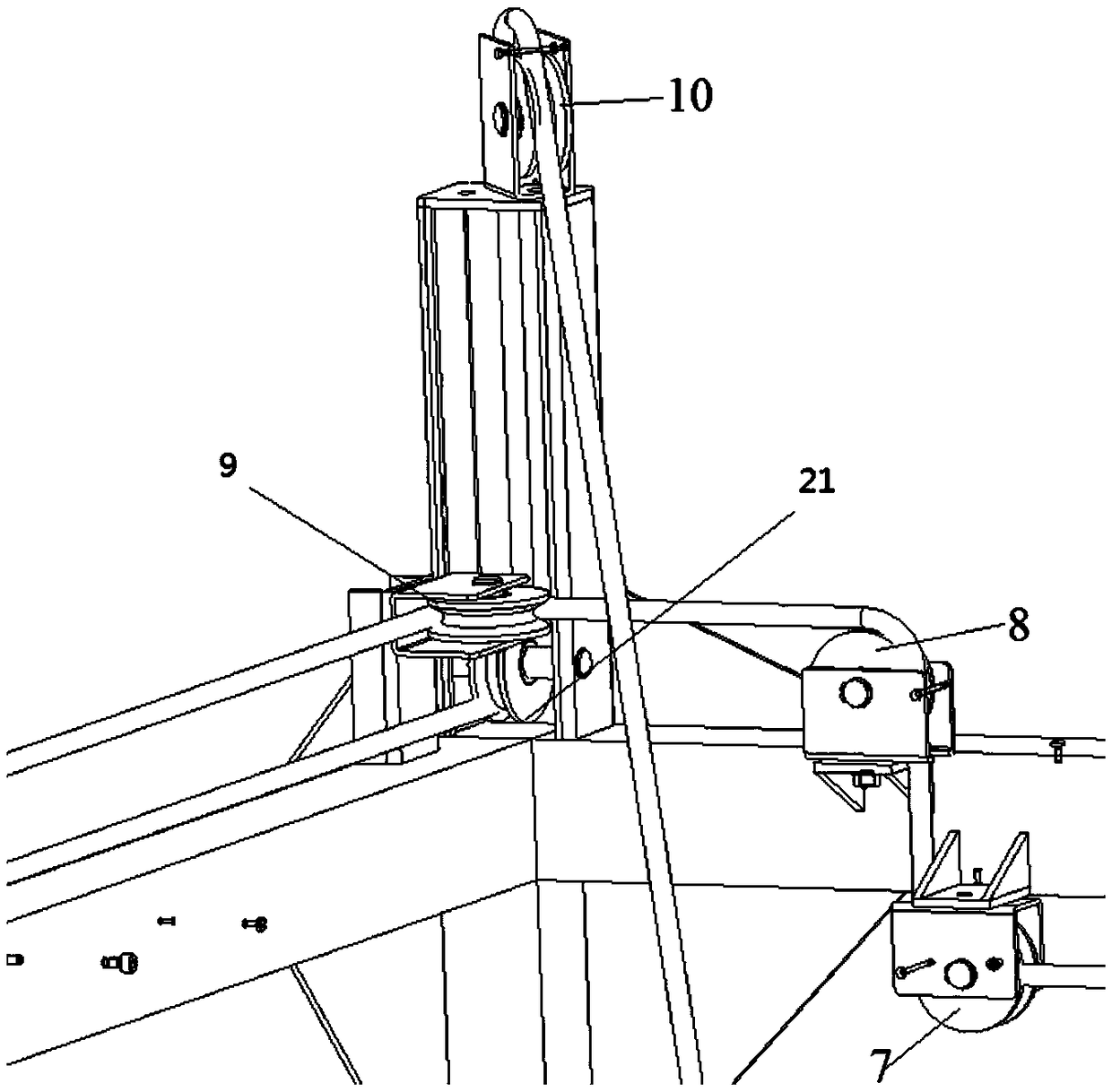

[0042] Such as Figure 1-3As shown, a lifting and turning device for aviation pallets, the four corners of the aviation pallets are provided with mooring rings, and the device includes a main frame, a turning mechanism I3, a turning mechanism II4, a winch 5, a guide pulley block, and a wire rope I24 , steel wire rope Ⅱ25, steel wire rope Ⅲ26, steel wire rope Ⅳ27, the main frame 1 is composed of supporting column Ⅰ1-1, supporting column Ⅱ1-2, supporting column Ⅲ1-3, supporting column Ⅳ1-4, beam Ⅰ2-1, beam Ⅱ2-2, Beam Ⅲ2-3 and beam Ⅳ2-4 constitute a rectangular parallelepiped frame structure, overturning mechanism Ⅰ3 is fixed in the middle of beam Ⅰ2-1, and overturning mechanism Ⅱ4 is located in the middle of beam Ⅳ2-4; winch 5 and wire rope Ⅰ24 are installed under the beam Ⅰ2-1. One end is located in the winch 5, and the other end is guided to the top of the support column III1-3 through the guide pulley; one end of the steel wire rope II25 is fixed to the steel wire rope I24 in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com