Acrylic sheet and preparation process thereof

A technology of acrylic sheet and preparation process, which is applied in the field of polymer materials, can solve the problems of no outdoor weather resistance, etc., and achieve the effect of excellent physical and mechanical properties, strong water resistance, and smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

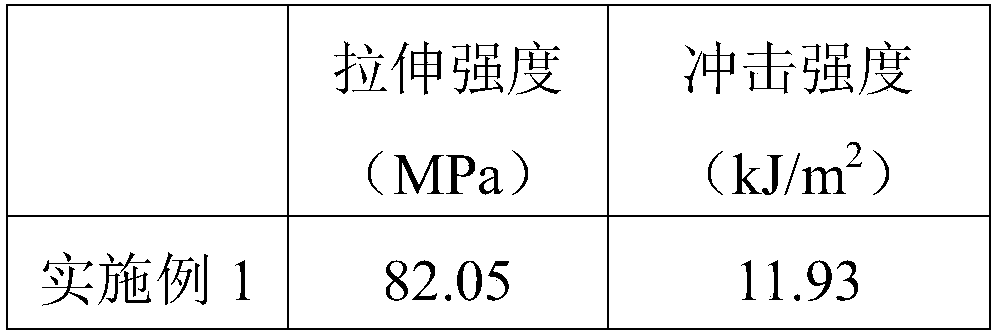

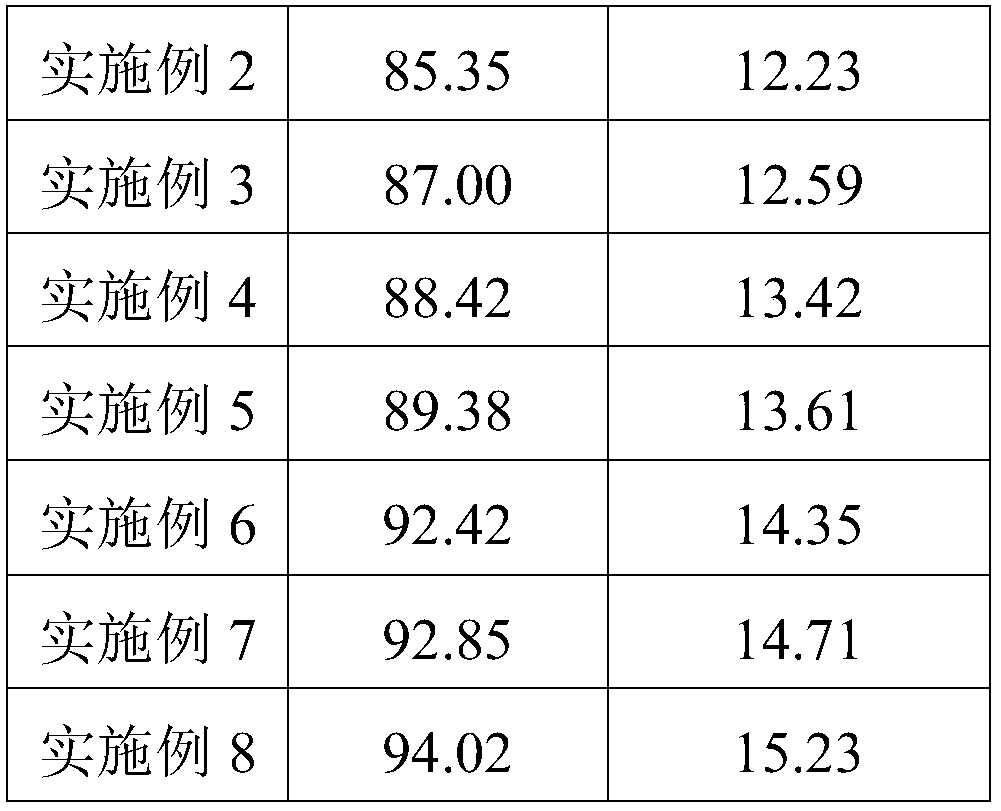

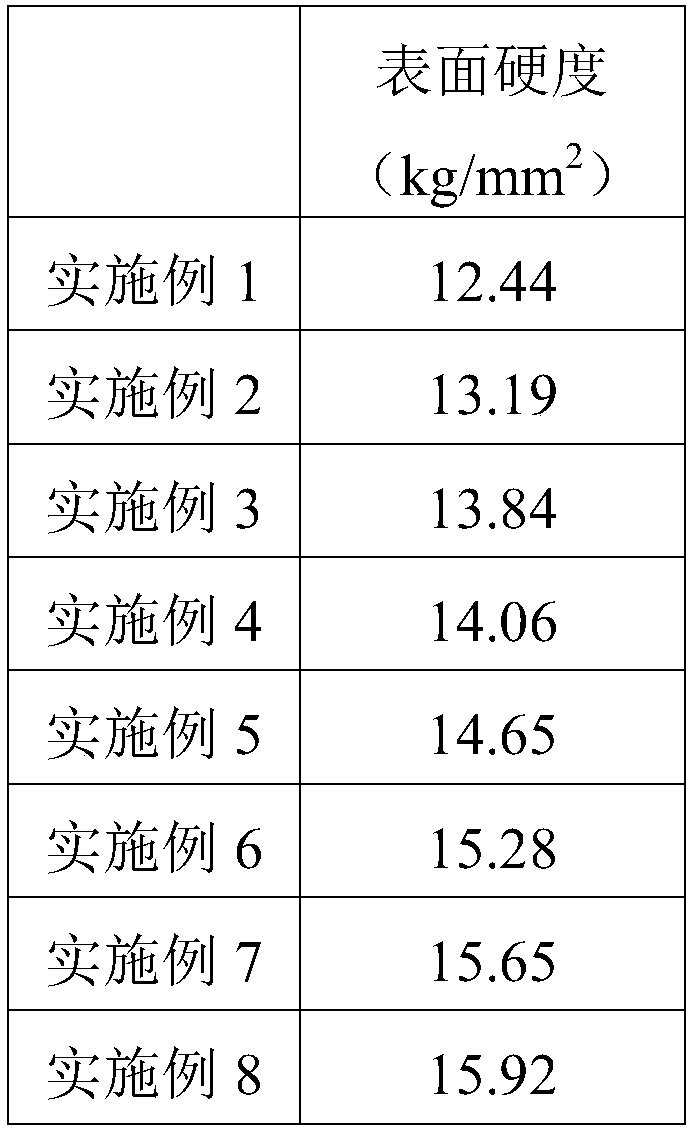

Examples

Embodiment 1

[0039]The preparation process of the acrylic sheet includes the following steps: after mixing methyl methacrylate, ethylene glycol dimethacrylate and azobisisobutyronitrile evenly according to the molar ratio of 1:0.02:0.003, pour it into the reaction kettle, Introduce nitrogen for 10 minutes; then stir and heat at 80 rpm to 70°C, pre-polymerize at 70°C for 1 hour, stop heating; quickly put the pre-polymerized reaction solution in an ice-water bath to cool to 40°C, pour into In the glass mold, let it stand for 30 minutes, and seal the glass mold with a polyvinyl chloride strip; then place the sealed glass mold at 60°C for 10 hours, at 80°C for 2 hours, at 100°C for 2 hours, and at 120°C for 2 hours. Hours, cooled naturally to 26°C, opened the glass mold, and obtained the acrylic sheet.

Embodiment 2

[0041] The preparation process of the acrylic sheet comprises the following steps: mixing methyl methacrylate, isobornyl methacrylate, ethylene glycol dimethacrylate and azobisisobutyronitrile according to the molar ratio of 0.85:0.15:0.02:0.003 After uniformity, pour it into the reaction kettle, and pass nitrogen gas for 10 minutes; then stir and heat to 70°C at 80 rpm, and stop heating after prepolymerization at 70°C for 1 hour; quickly put the prepolymerized reaction solution into ice Cool in a water bath to 40°C, pour it into a glass mold, let it stand for 30 minutes, and seal the glass mold with a polyvinyl chloride strip; then place the sealed glass mold at 60°C for 10 hours, and place it at 80°C for 2 hours, 100 ℃ for 2 hours, 120 ℃ for 2 hours, naturally cooled to 26 ℃, and the glass mold was opened to obtain the acrylic sheet.

Embodiment 3

[0043] The preparation process of the acrylic sheet comprises the following steps: after mixing evenly methyl methacrylate and nano-bentonite with 0.05 times the weight of the methyl methacrylate, adding 3-(trimethoxysilyl methacrylate) with 0.2 times the weight of the nano-bentonite ) propyl ester, stirred at 40° C. with 80 rpm for 24 hours in a nitrogen atmosphere to obtain a methyl methacrylate dispersion of 3-(trimethoxysilyl) propyl methacrylate modified nano-bentonite; The methyl methacrylate dispersion liquid of 3-(trimethoxysilyl)propyl acrylate modified nano-bentonite, isobornyl methacrylate, ethylene glycol dimethacrylate and azobisisobutyronitrile were mixed evenly Afterwards, methyl methacrylate, isobornyl methacrylate, ethyl dimethacrylate in the methyl methacrylate dispersion liquid of described 3-(trimethoxysilyl) propyl methacrylate modified nano-bentonite The molar ratio of diol ester to azobisisobutyronitrile is 0.85:0.15:0.02:0.003, pour it into the reaction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com