Polypropylene composition for improving surface flame treatment effect and preparation method of polypropylene composition

A polypropylene composition and a flame treatment technology are applied in the polypropylene composition and its preparation, the polypropylene composition for improving the surface flame treatment effect and the preparation field thereof, and can solve the problem that the improvement of the surface energy is not very obvious and the surface energy is not very obvious. It can improve the problems of limited improvement and poor surface flame treatment effect, so as to achieve the effect of good flame treatment surface and adhesive performance, and improve surface tension and wettability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

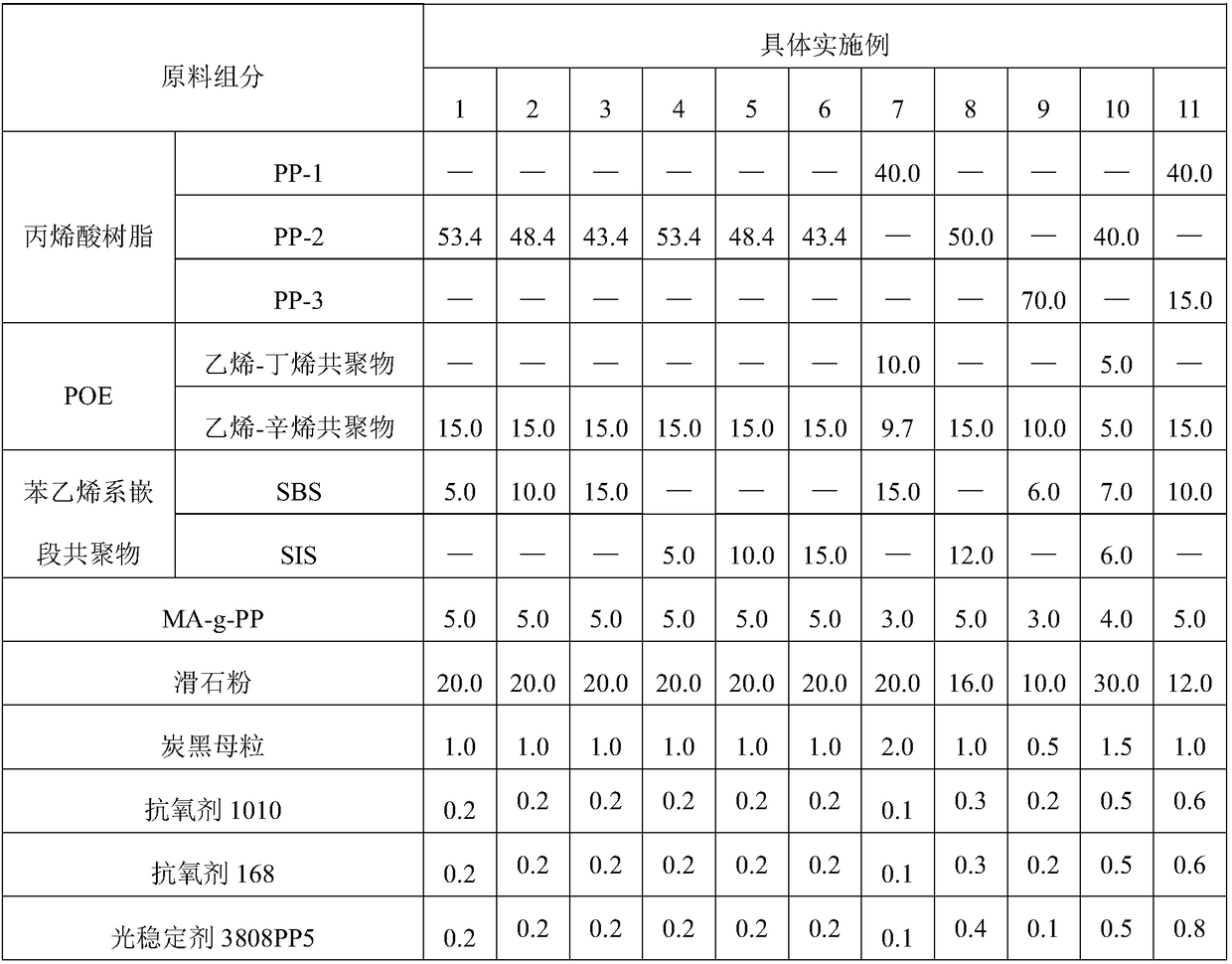

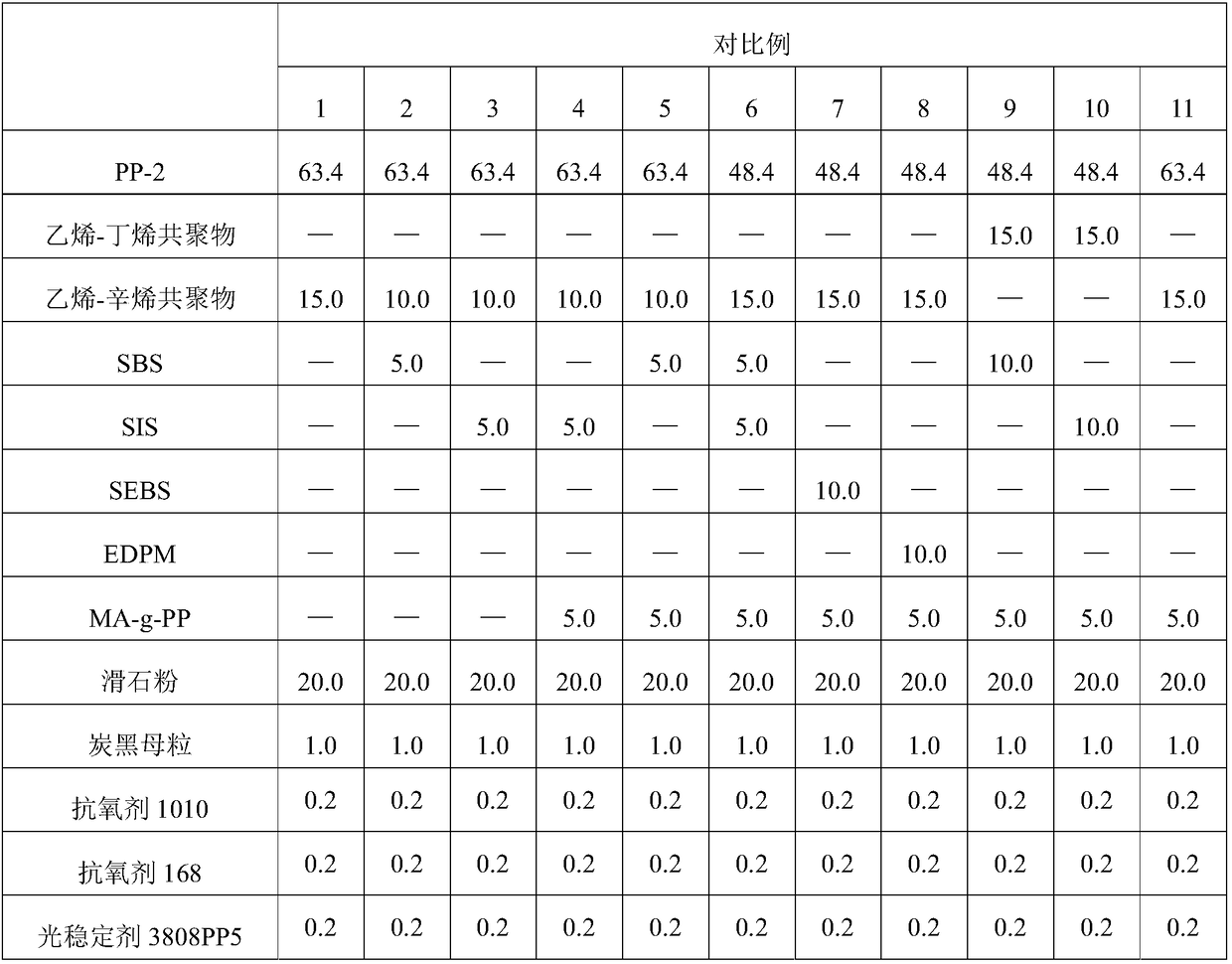

Examples

Embodiment 1

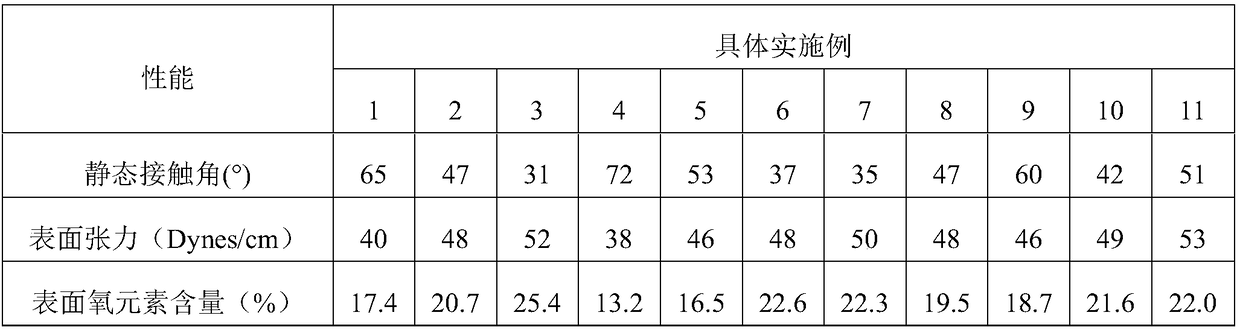

[0045] Compared with Example 4 in Example 1, compared with Example 5 in Example 2, compared with Example 6 in Example 3, under the same addition amount, the surface contact angle of adding SBS after flame treatment is smaller , greater surface tension and higher surface oxygen content.

[0046] Compared with Example 1, the content of POE is reduced in Comparative Example 5, and under the same SBS content, Comparative Example 5 has a better surface treatment effect.

[0047] Compared with Example 4, the content of POE is reduced in Comparative Example 4. Under the same SIS content, Comparative Example 4 has a better surface treatment effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com