Small-hole type pulse tube thermoacoustic refrigerator

A thermoacoustic refrigerator and pulse tube technology, which is applied in the field of refrigerators and small-hole pulse tube thermoacoustic refrigerators, can solve the problems of low efficiency of the whole machine, achieve good cooling effect, improve efficiency, and reduce sound power loss Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

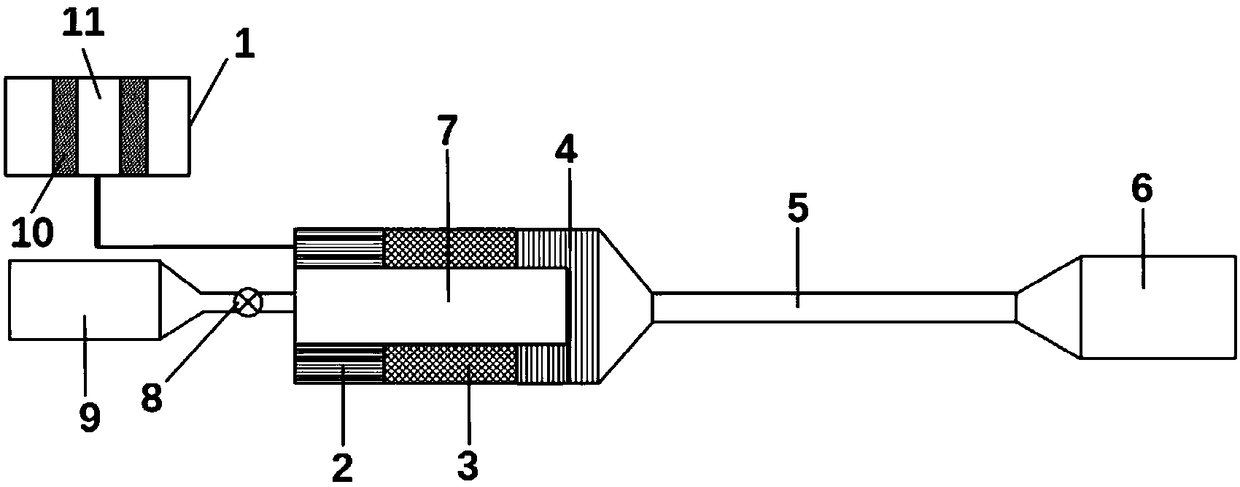

[0030] Such as figure 1 As shown, the refrigerator of this embodiment consists of a compressor 1, a hot-end heat exchanger 2, a regenerator 3, a cold-end heat exchanger 4, a resonant tube 5, a first gas storehouse 6, a pulse tube 7, and an orifice valve 8. The second gas storehouse 9 is composed.

[0031] The compressor 1 is composed of a piston 10 and a cylinder, forming a compression chamber 11 . One end of the compression chamber 11, the hot-end heat exchanger 2, the regenerator 3, and the cold-end heat exchanger 4 is connected in sequence, and the other end of the cold-end heat exchanger 4 is respectively connected to the resonant tube 5 and the pulse tube 7 through connecting parts. The other end of the resonant tube 5 is connected to the first gas reservoir 6, and the hot end of the pulse tube 7 is connected to the second gas reservoir 9 through an orifice valve 8.

[0032] The piston 10 is generally driven by a linear motor, and may also be driven by other prime mover...

Embodiment 2

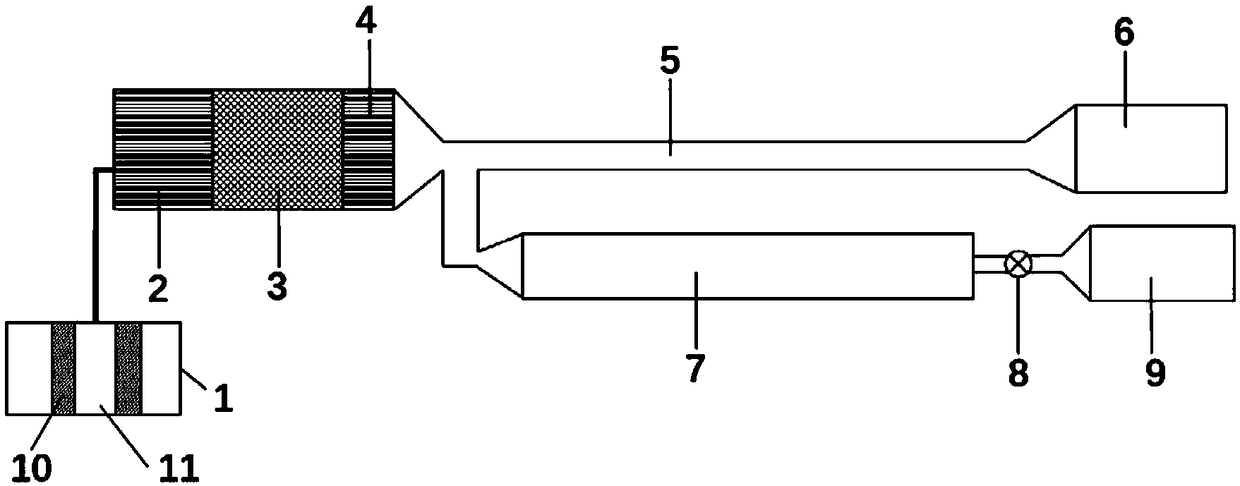

[0038] Such as figure 2 shown, with figure 1 The structural parts are the same, figure 2 A linear arrangement structure of the pulse tube 7 and the heat exchanger 2 at the hot end, the regenerator 3 and the heat exchanger 4 at the cold end is adopted. Its implementation method is similar to embodiment 1.

Embodiment 3

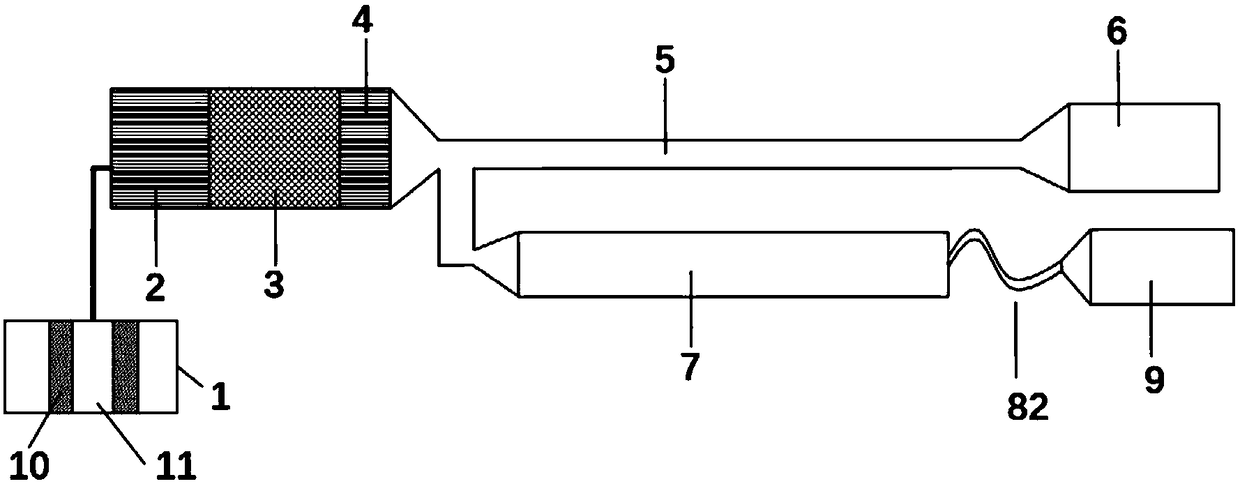

[0040] Such as image 3 Shown, compared with embodiment 2, will figure 2 The small hole structure in the structure is changed to an inertial tube structure, and the phase adjustment ability of the inertial tube 82 is better than that of the small hole valve 8. Therefore, in this structure, the optimal phase of the pressure wave and mass flow can be obtained in the regenerator, thereby Further improve the efficiency of the whole machine. Especially when the cooling capacity is small, the phase adjustment capability of the inertia tube 82 is insufficient, and the resonant tube 5 can greatly increase the phase modulation capability. Thereby increasing the cooling efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com