Ultrasonic visual detection method and ultrasonic visual detector

A detection method, ultrasonic technology, applied in the direction of using acoustic measurement for testing, optical method for testing, testing dielectric strength, etc. problems, to achieve the effect of easy-to-understand detection efficiency, accurate detection data, and easy portability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

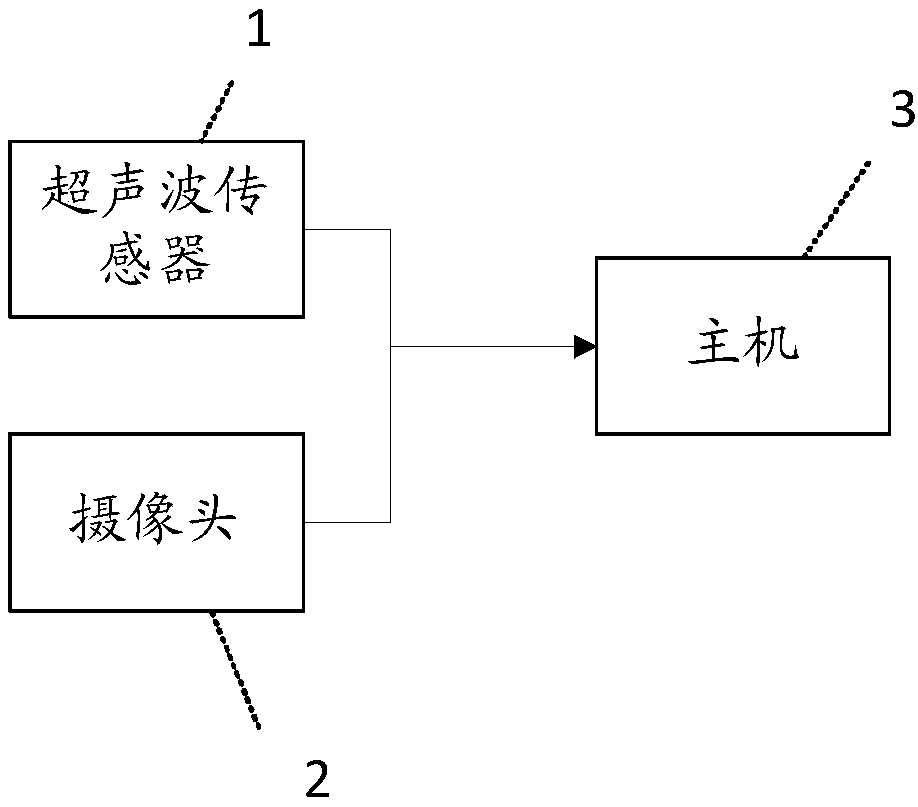

[0062] Please refer to figure 1 and figure 2 , this embodiment provides an ultrasonic visualization detector, such as figure 2 As shown, including the detector 01 and the host 02, the detector 01 and the host 02 are connected through a high-frequency signal transmission cable (namely, the shielded cable 03). As the signal transmission line between the two, it can effectively prevent external interference during signal transmission. and signal attenuation. Preferably, the structure is a multi-core shielded cable, such as a four-core shielded cable.

[0063] The detector 01 is equipped with an ultrasonic sensor 1 and a camera 2 . The detection angle of view of the ultrasonic sensor 1 corresponds to the imaging angle of view of the camera 2; that is, the signal detection point of the ultrasonic sensor is set at the same point as the imaging focus of the camera. Specifically, the ultrasonic signal propagates along a straight line within a certain distance, and the camera als...

Embodiment 2

[0073] This embodiment is further expanded on the basis of the first embodiment, and its functions are enriched. The similarities will not be repeated, the differences are:

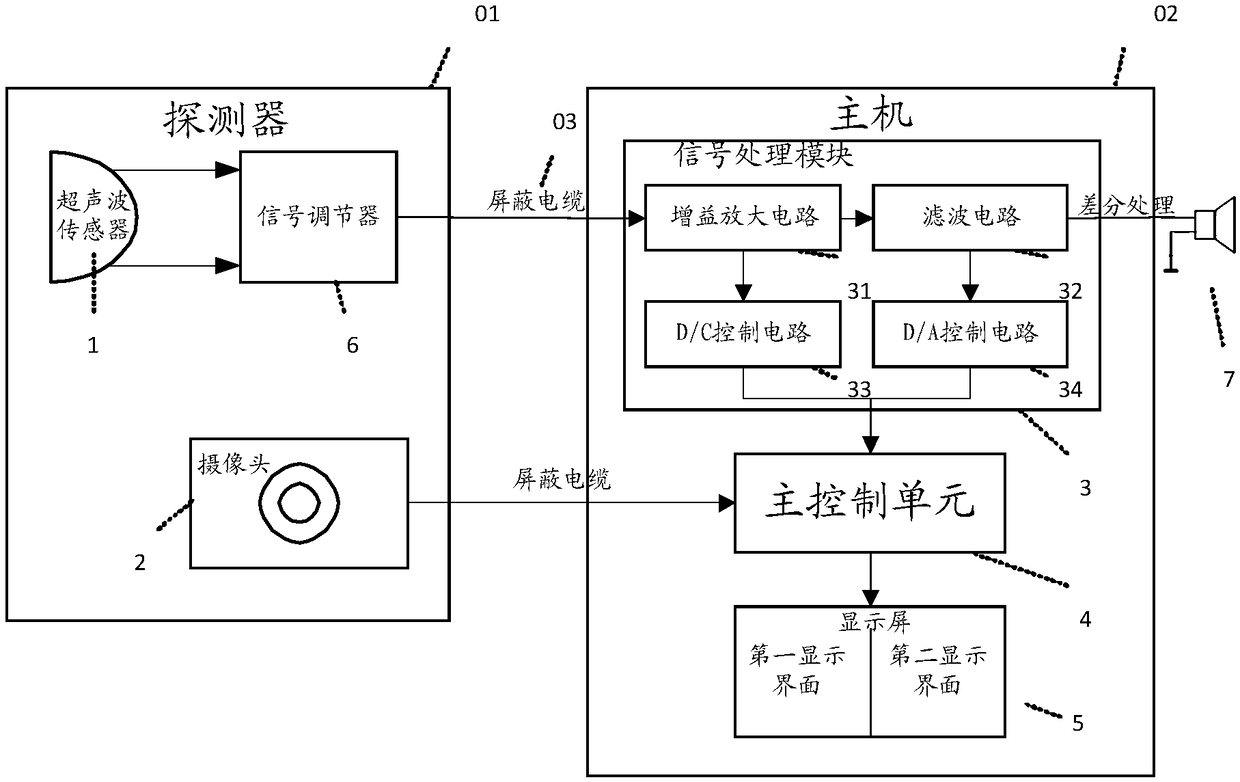

[0074] Such as image 3 As shown, the host 02 specifically includes a signal processing module 3, a main control unit 4 and a display screen 5; the display screen 5 is configured with a first display interface and a second display interface.

[0075] The ultrasonic sensor 1 , the shielded cable 03 , the signal processing module 3 , the main control unit 4 and the display screen are connected sequentially; the camera, shielded cable, main control unit and the display screen are connected sequentially.

[0076] The signal processing module 3 is configured to convert the ultrasonic signal collected by the ultrasonic sensor into an audio signal audible to the human ear through fast Fourier transform, and generate a corresponding audio waveform spectrogram according to the audio signal. In this way, the ultr...

Embodiment 3

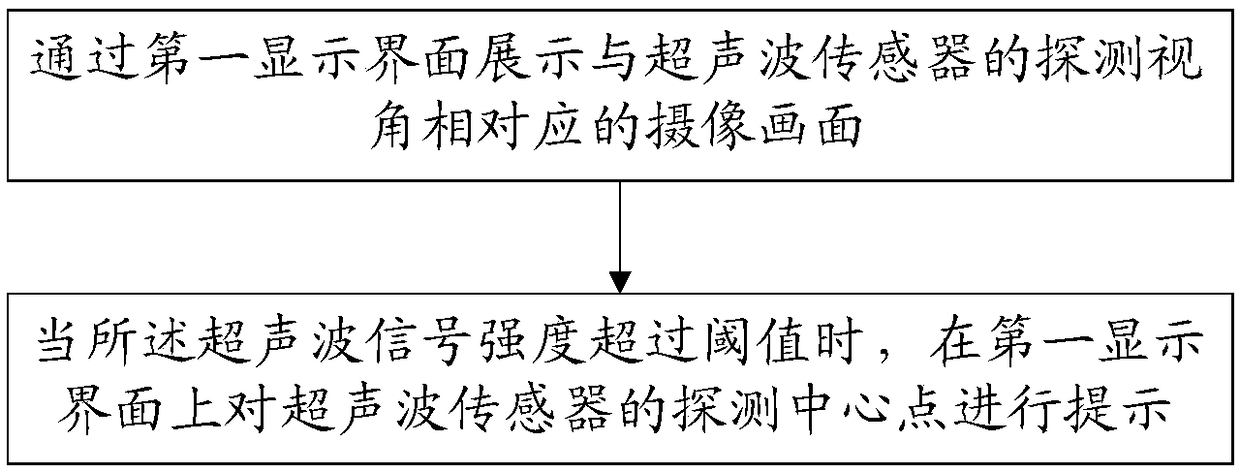

[0102] This embodiment is an ultrasonic visualization detection method corresponding to the first embodiment above, including:

[0103] Displaying a camera picture corresponding to the detection angle of view of the ultrasonic sensor through the first display interface;

[0104] When the ultrasonic signal strength exceeds the threshold, the detection point of the ultrasonic sensor is prompted on the first display interface.

[0105] Specifically, the eye-catching degree of the prompt is directly proportional to the strength of the ultrasonic signal.

[0106] The prompt is to mark the water ripples with a preset number of circles; the greater the strength of the ultrasonic signal, the more circles of the marked water ripples.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com