Soliton optical frequency comb generation device and operation method thereof

A technology for generating devices and optical frequency combs, applied in the field of optical frequency combs, can solve the problems of optical frequency combs that cannot control the state of single solitons through programs, poor repeatability of experimental results, etc., and achieve the effects of reducing complexity and suppressing noise disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the protection scope of the present invention should not be limited thereby.

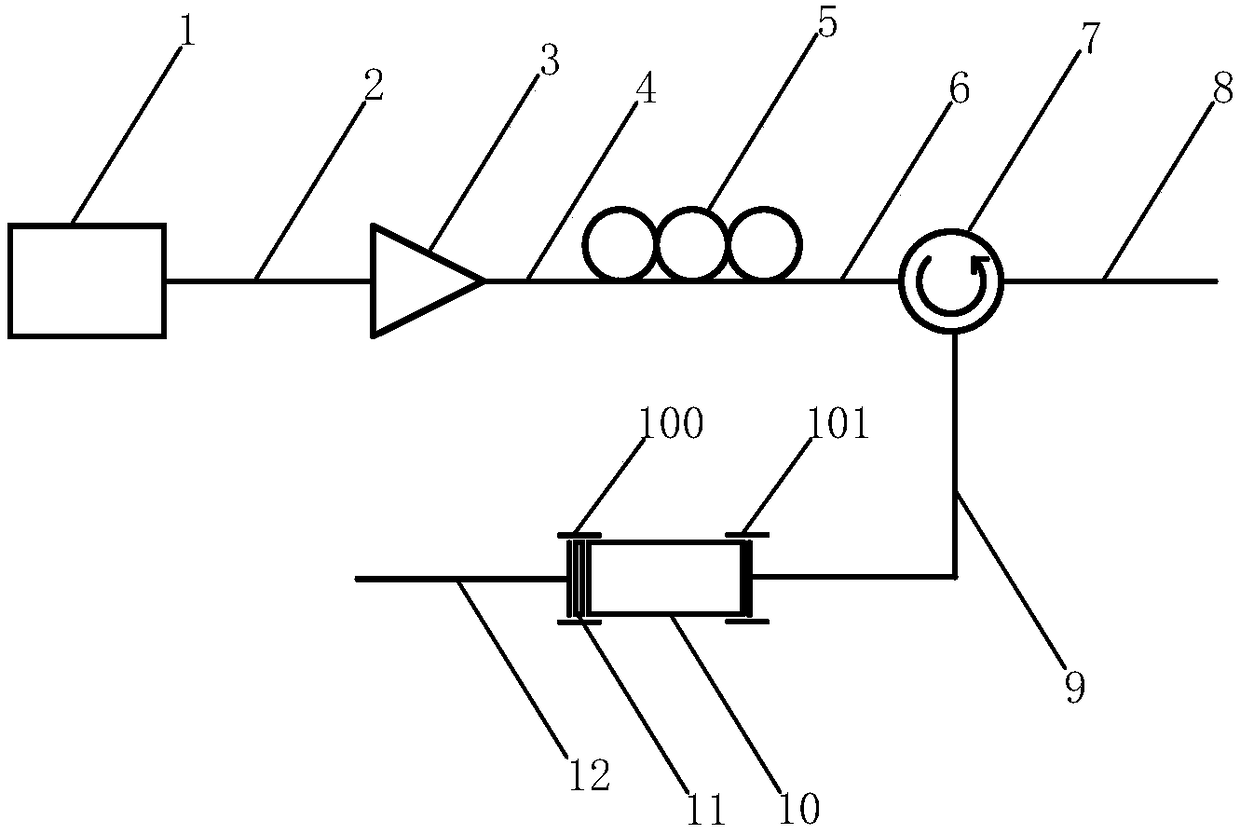

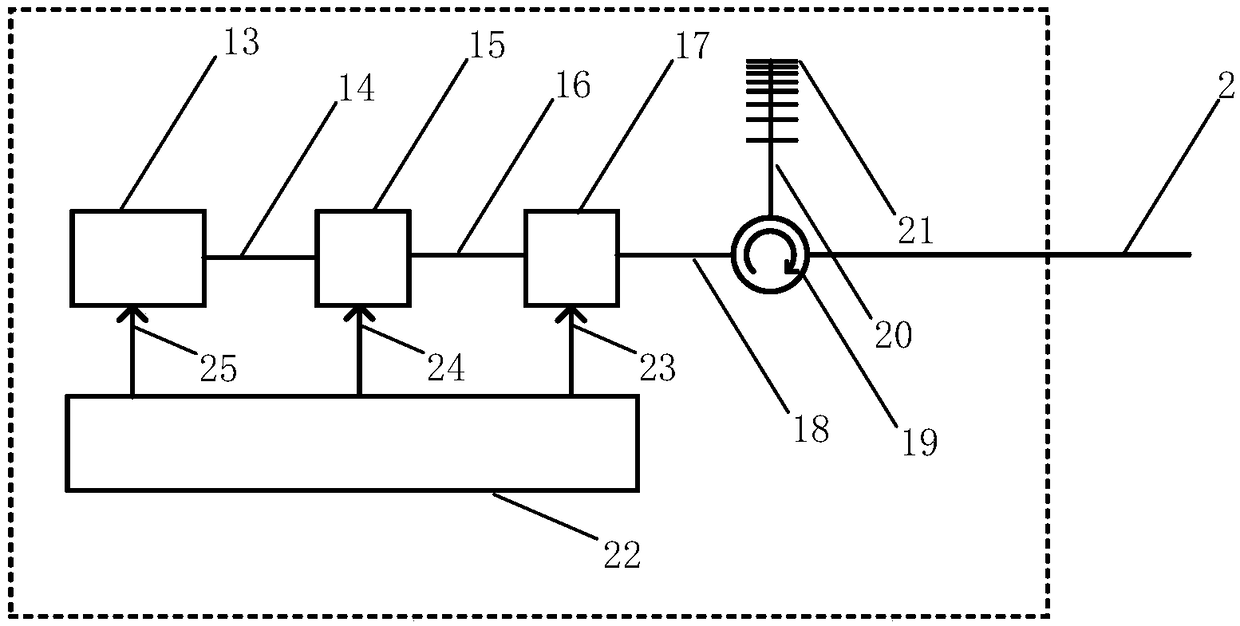

[0039] figure 1 It is a structural diagram of the soliton optical frequency comb generating device of the present invention. It can be seen from the figure that the soliton optical frequency comb generating device of the present invention includes: an adjustable pulsed optical laser 1, a first connecting optical fiber 2, an optical amplifier 3, and a second connecting optical fiber 4 , polarization controller 5, third connection fiber 6, first circulator 7, auxiliary test output fiber 8, fourth connection fiber 9, ceramic ferrule microcavity 10, single-layer graphene 11, output fiber 12, first C Type C ceramic tube 100 and the second C type ceramic tube 101, along the laser output direction of the adjustable pulse laser 1 are the first connecting optical fiber 2, the optica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com