Drinking type fruit pulp flavor yogurt and preparation method thereof

A drinkable and yogurt technology, applied in milk preparations, applications, dairy products, etc., can solve the problems of losing the mellow feeling of yogurt, and the viscosity cannot maintain the uniform suspension of fruit particles, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

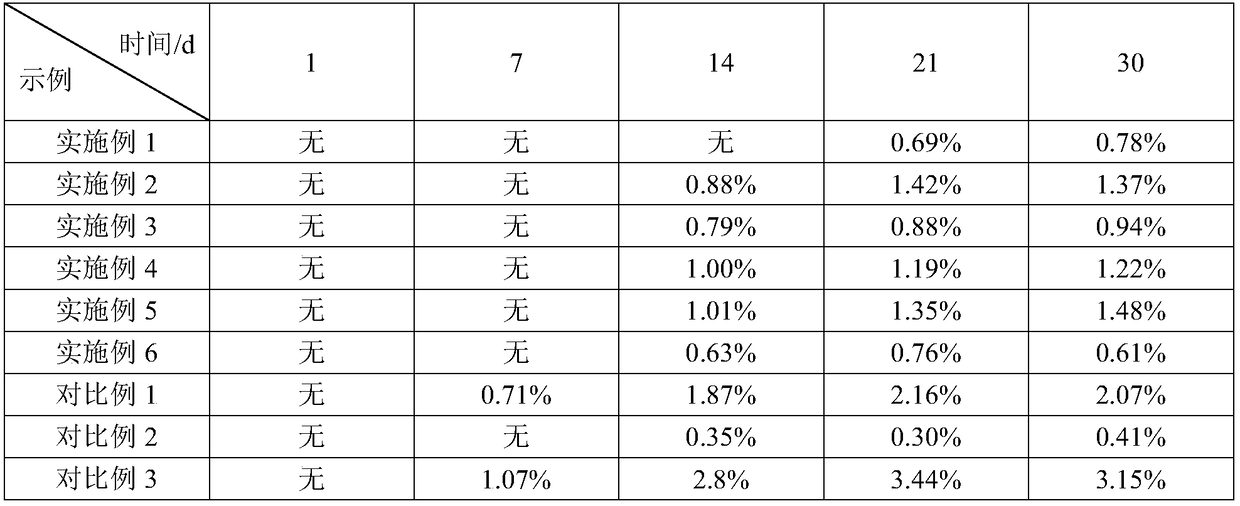

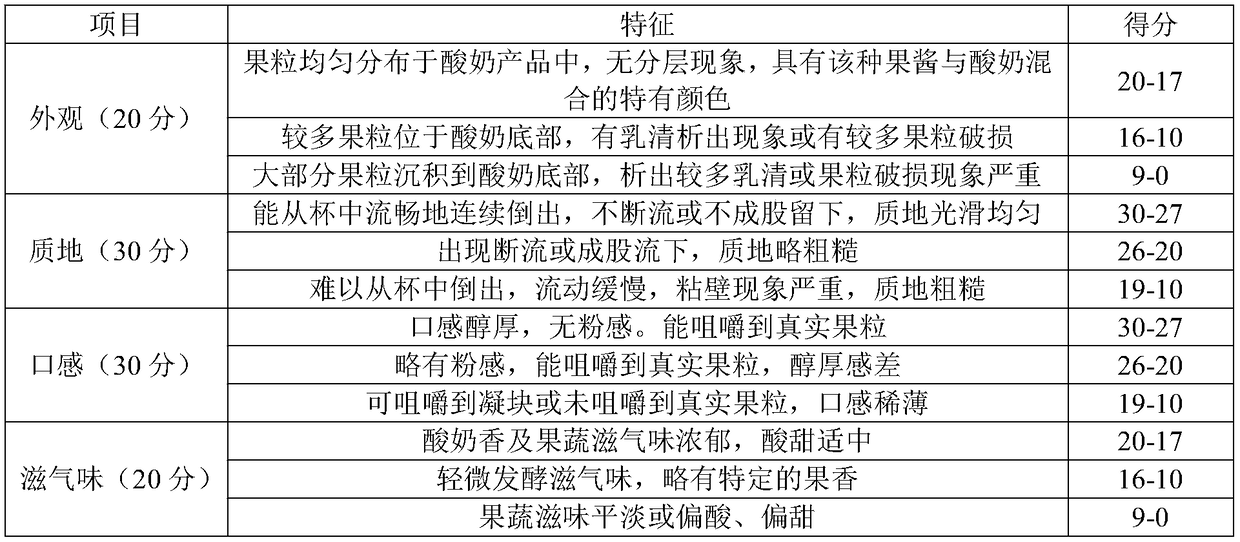

Examples

preparation example Construction

[0020] In a specific embodiment, a kind of preparation method of drinkable fruit flavored yoghurt is provided, and the preparation method comprises the following steps:

[0021] (1) After mixing raw milk, white sugar, cream and concentrated milk protein powder, homogenizing, sterilizing and cooling, adding a starter for fermentation, and fermenting until the acidity at the end point is 68-70°T to obtain a yogurt base;

[0022] (2) Demulsify the yogurt base material, cool it, and smooth it with a smoothing pump with a rotation speed of 1500-2600rpm at 15-25°C;

[0023] (3) adding the jam to the processed yoghurt base, stirring and mixing, filling and cooling to obtain the product;

[0024] In the above preparation method, the mass volume ratio of raw milk, white sugar, cream, concentrated milk protein powder and jam is 80-90L: 5-11kg: 0.4-0.8kg: 0.4-0.8kg: 10L.

[0025] The invention optimizes smoothing treatment parameters through an adjusted homogenization method, and only n...

Embodiment 1

[0038] A preparation method of drinking type fruit flavor yoghurt comprises the following steps:

[0039] (1) Mix 80L of raw milk with 7kg of white sugar, 0.4kg of cream and 0.4kg of MPC70 at 40°C for 20 minutes, homogenize at 60°C and pressure of 150+80bar, sterilize at 90°C for 10 minutes and cool to 40°C ℃, insert 2.4g of starter (the inoculum size of starter is 2×10 6 cfu / mL), the fermentation end point was stopped at 68°C;

[0040] (2) Demulsify the obtained curd, the demulsification stirring paddle is a three-blade stirrer, the stirring speed is 30rpm, and the stirring time is 15min; the yogurt base material after the demulsification is cooled to 15°C, and it is set aside after being treated by a smoothing pump at 1500rpm;

[0041] (3) Add 10L of blueberry jam to the treated yogurt base and stir for 15 minutes at a stirring speed of 4 rpm. The mixed product is filled into Tetra Pak TT tanks and stored in refrigeration.

Embodiment 2

[0043] A preparation method of drinking type fruit flavor yoghurt comprises the following steps:

[0044] (1) Mix 85L of raw milk with 5kg of white sugar, 0.4kg of cream and 0.8kg of MPC70 at 45°C for 30 minutes, homogenize at 65°C and pressure of 200+30bar, sterilize at 95°C for 5 minutes and cool to 45°C, insert 8.5g of starter (the inoculum size of starter is 0.1×10 6 cfu / mL), the fermentation end point stops fermentation to 70 ° of T;

[0045] (2) The obtained curd is demulsified, and the demulsification stirring paddle is a three-blade stirrer, the stirring speed is 30 rpm, and the stirring time is 15 minutes. The yogurt base material after the demulsification is cooled to 25 ° C, and it is used after being treated by a smoothing pump at 2400 rpm;

[0046] (3) 10L of strawberry jam was added to the treated yoghurt base, and stirred for 10 min at a stirring speed of 8 rpm. The mixed product is filled into Tetra Pak TT tanks and stored in refrigeration.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com