Photocatalytic flue gas mercury removal device in power plant chimney

A technology of photocatalysis and flue gas, which is applied in the direction of gas treatment, chemical instruments and methods, and separation of dispersed particles, can solve the problems of limited mercury removal efficiency, and achieve the goal of increasing adsorption and photocatalytic reaction efficiency, improving efficiency, and increasing efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

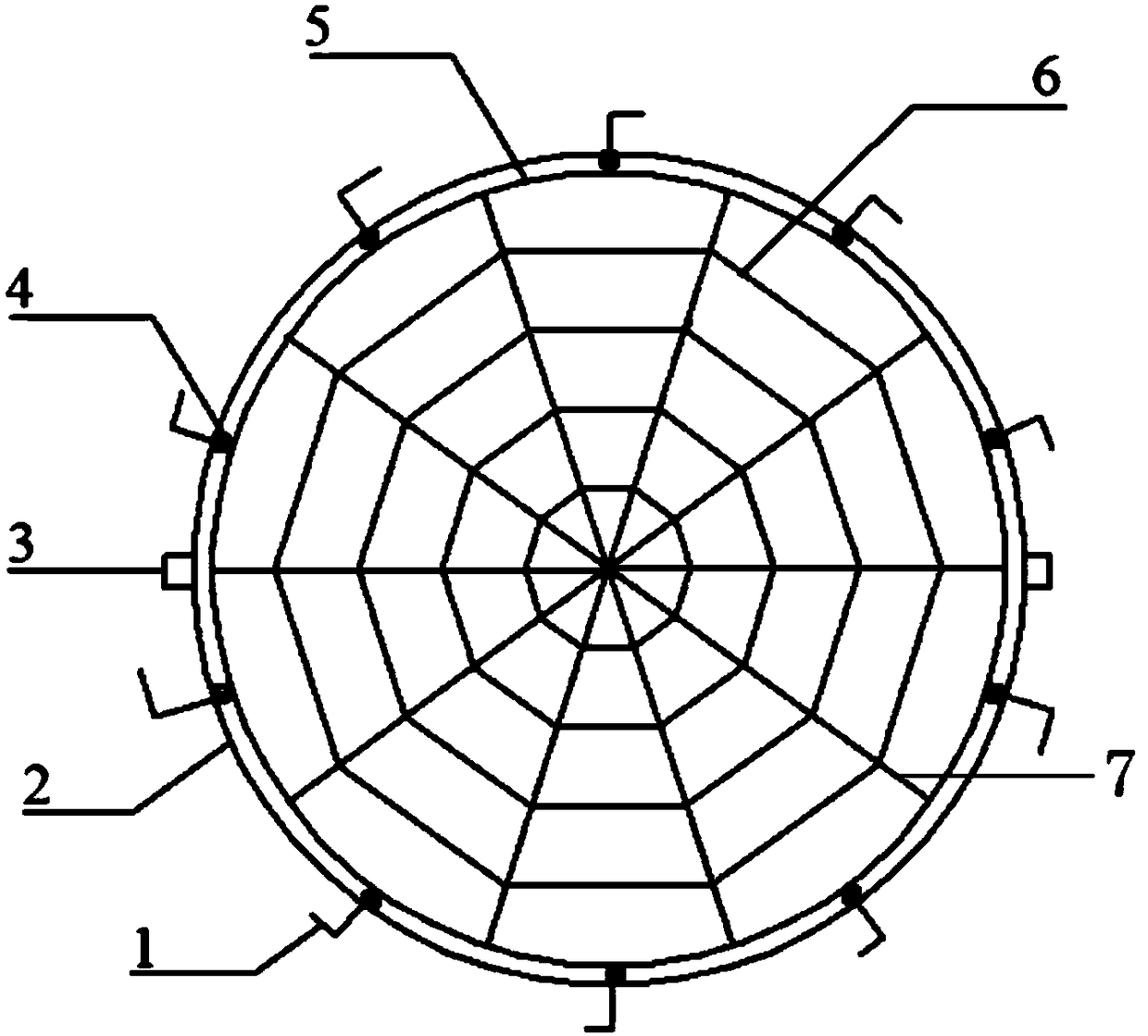

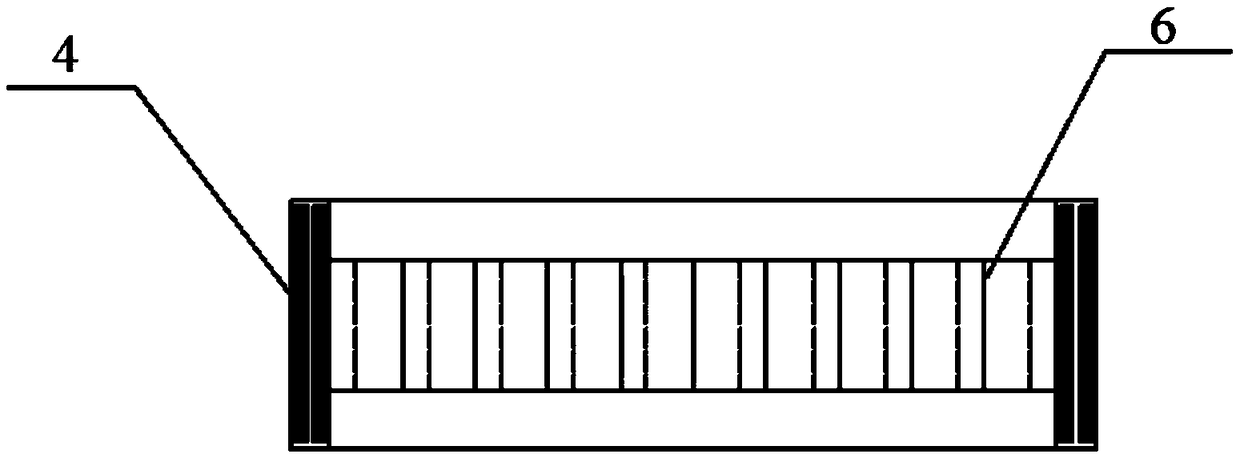

[0028] Such as figure 1 , 2 As shown, a photocatalytic flue gas mercury removal device in a power plant chimney includes a housing, a UV ultraviolet lamp unit disposed in the housing, and a photocatalytic reaction unit disposed in the housing. The photocatalytic reaction unit consists of a plurality of metal sheets 6 Composition, the metal flakes 6 are radially arranged in a "spider web" structure centered on the axis of the housing, and the surface of the metal flakes 6 is loaded with a catalyst. In this embodiment, the photocatalyst is TiO 2 / BiOIO 3 Specifically, different metal sheets 6 are connected and arranged uniformly and symmetrically around the center of the shell to form a "spider web" radiation structure, which can greatly increase the contact time and contact area when the smoke passes through the structure, and the "spider The "mesh" structure has little resistance to the flow of smoke.

[0029] The shell is cylindrical and consists of an inner shell 5 and an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com