Power output equipment, hydraulic stirrer, high-pressure reaction kettle including power output equipment and hydraulic stirrer, and system

A high-pressure reactor and power output technology, which is applied to mixers with rotating stirring devices, mechanical equipment, mixer accessories, etc., can solve problems such as shortened service life, accelerated bearings, and corrosion of equipment to achieve safe, economical, and efficient operation. The effect of long equipment life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

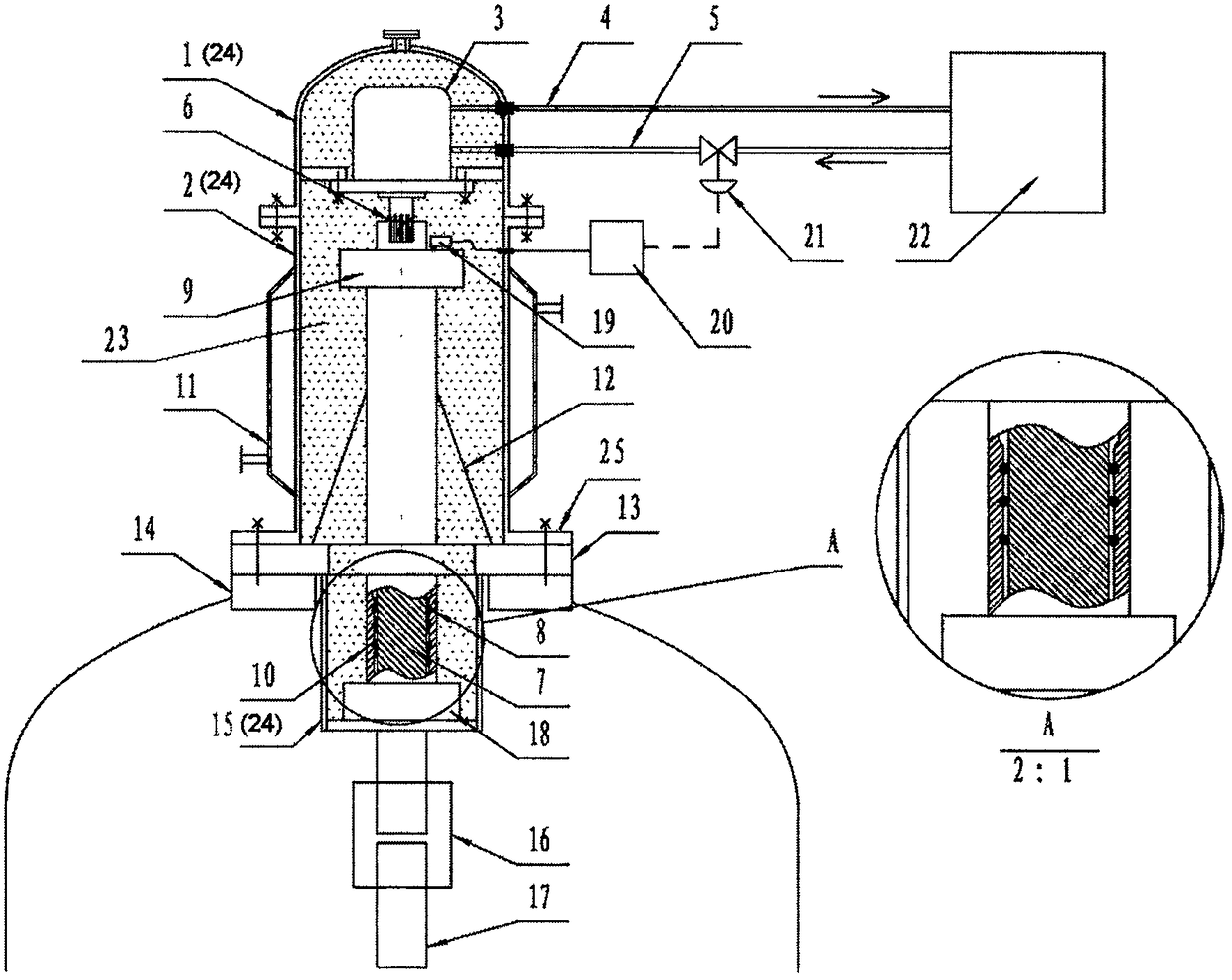

[0061] figure 2is a schematic diagram of one embodiment of a stirrer according to the present application. Wherein, the agitator includes a power output device according to the present application, and the power output device includes a hydraulic motor (3), and the hydraulic motor has a motor coupling (6), a power output shaft (7) and a hydraulic oil pipe (4, 5), the motor coupling (6) is connected to one end of the power output shaft (7), and the power of the hydraulic motor (3) is transmitted to the power through the motor coupling (6) Output shaft (7); shielding case (24), described shielding case (24) has an open end, and described open end is equipped with support sleeve (10), and described hydraulic motor (3) is accommodated in described shielding case ( 24), the other end of the power output shaft (7) passes through the support sleeve (10) for power output, and the hydraulic oil pipes (4, 5) pass through the shield cover (24) , used to connect the hydraulic station (...

Embodiment 2

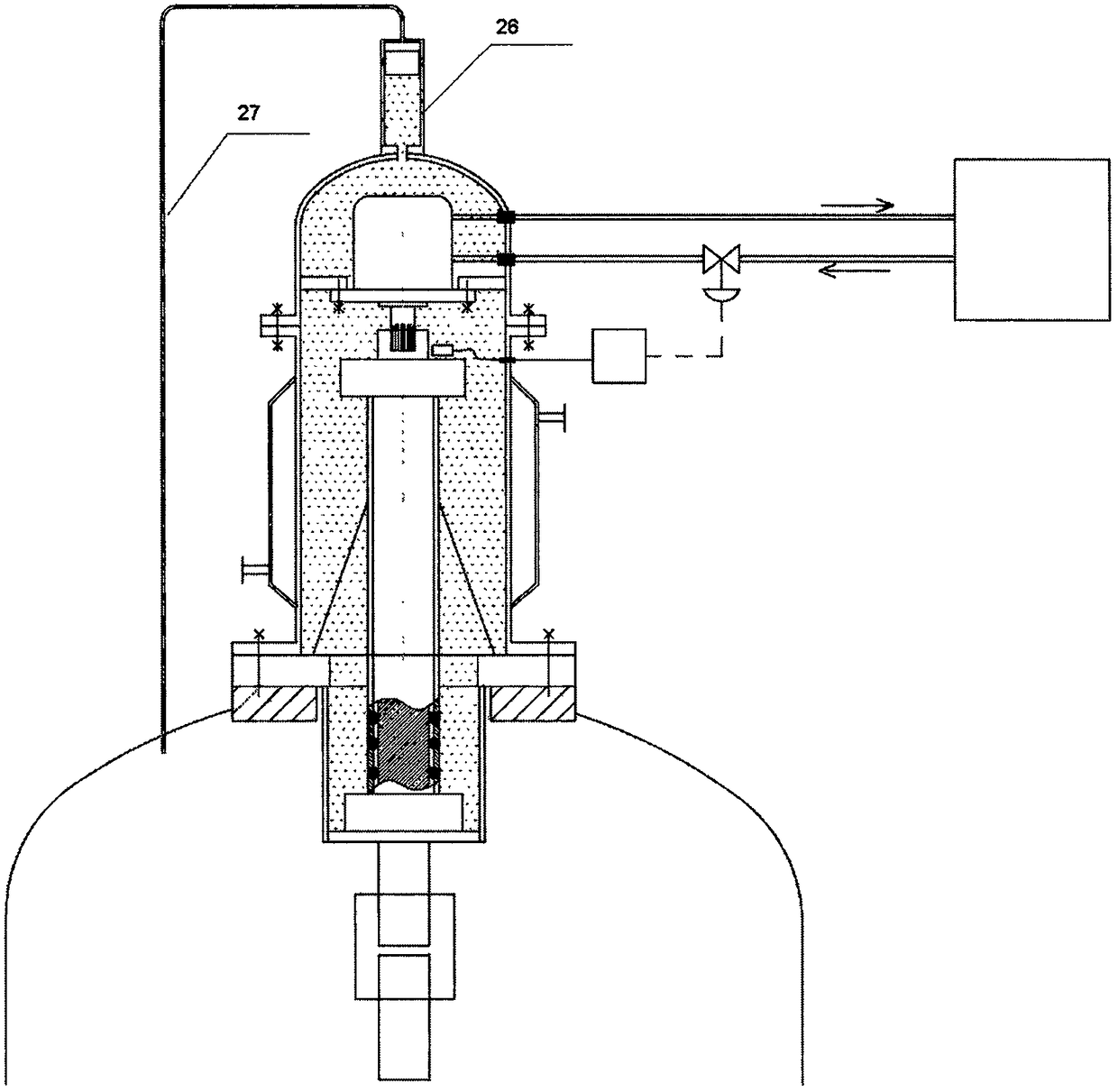

[0066] image 3 is a schematic diagram of one embodiment of a stirrer according to the present application. its structure and figure 2 The difference is that a piston (26) and a connecting pipe (27) are arranged on the shielding cover, and one end of the piston (26) communicates with the inside of the shielding cover (24), and the piston (26 ) is connected to the communication pipe (27), and the communication pipe (27) communicates with the inside of the high pressure reactor. Such design can make the incompressible fluid (being hydraulic oil 23) in the shielding cover keep balance when subjected to upper pressure and lower pressure, and the pressure in the hydraulic oil (23) is the pressure of the reactor, or in other words and the pressure of the reactor. The pressure is very close.

Embodiment 3

[0070] Figure 4 It is another embodiment of the present application, which is similar to the technical solution of Embodiment 1, except that the sealing connection between the support plate and the upper and lower cylinders of the shield adopts a different design. In the present application, the specific design of the support plate is not limited, as long as the upper and lower sealing surfaces of the support plate can achieve a good sealing effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com