Iron-containing graphene oxide modified graphite felt electrode and preparation method and application thereof

A graphite felt and graphene technology is applied in the field of graphite felt electrodes modified by iron-containing graphene oxide and its preparation, which can solve the problems of difficulty in guaranteeing stability, narrow pH range, inability to catalyze reduction, etc. The effect of shortening the reaction time and reducing the preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

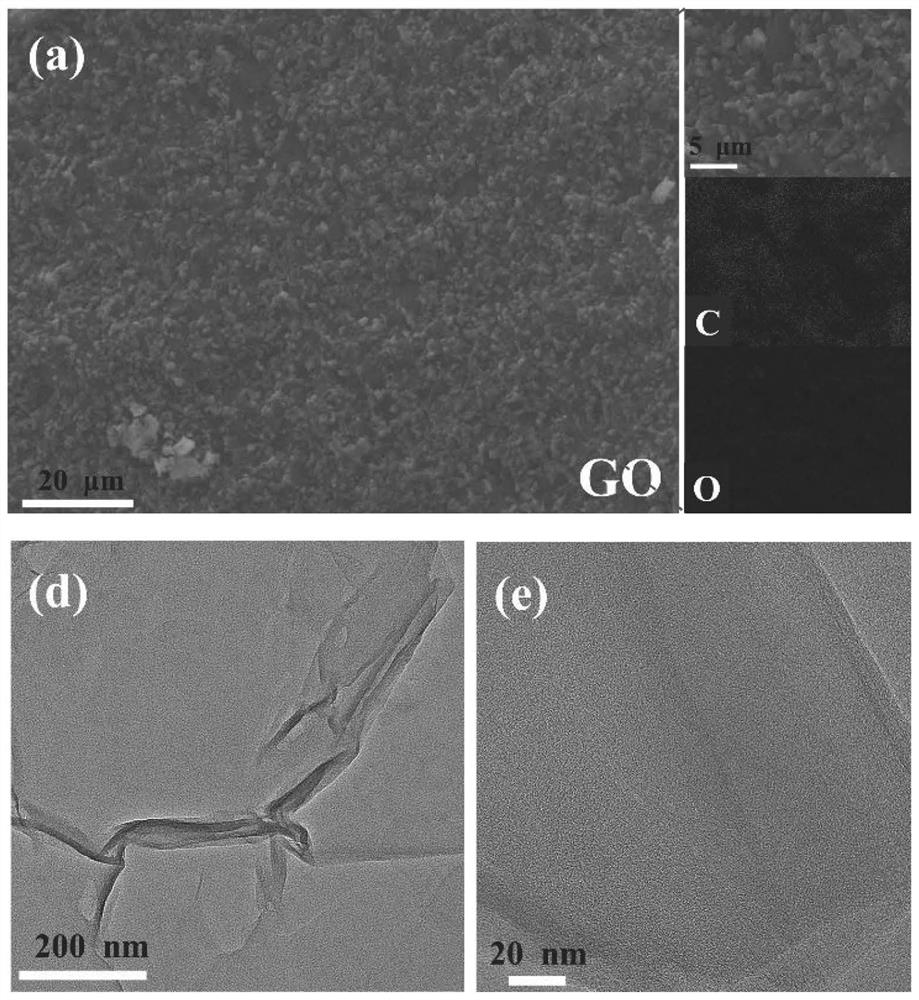

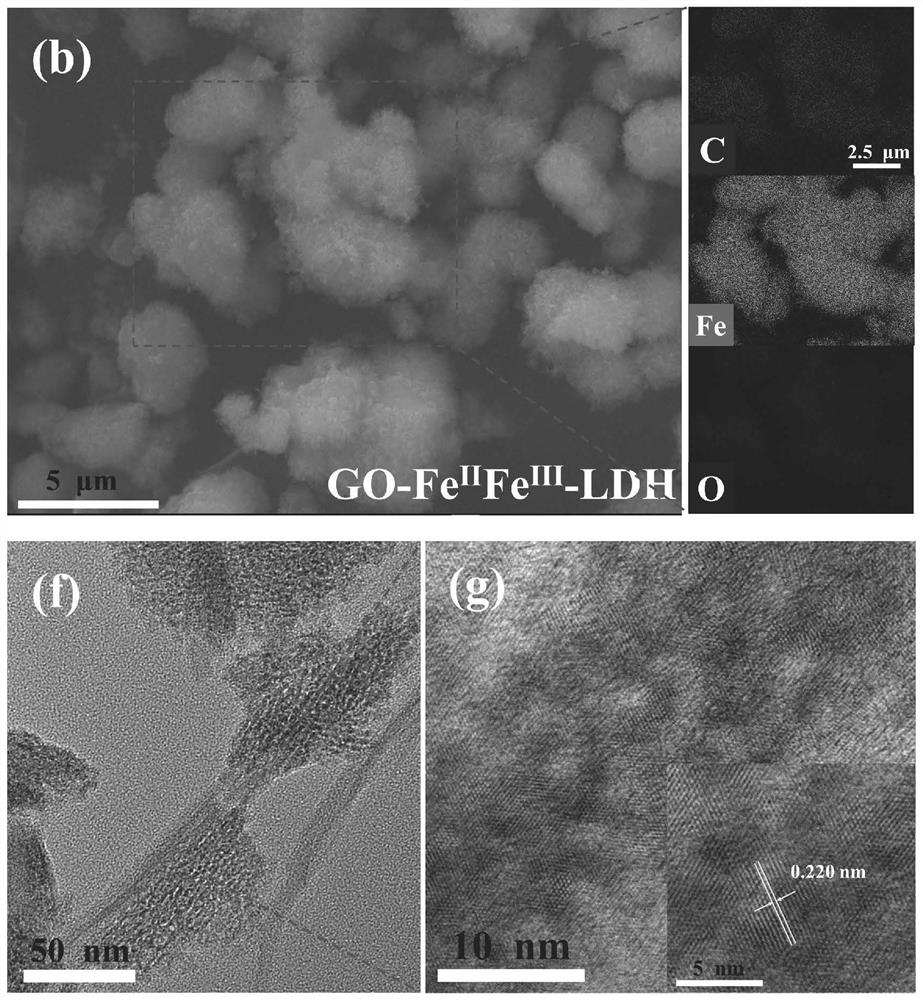

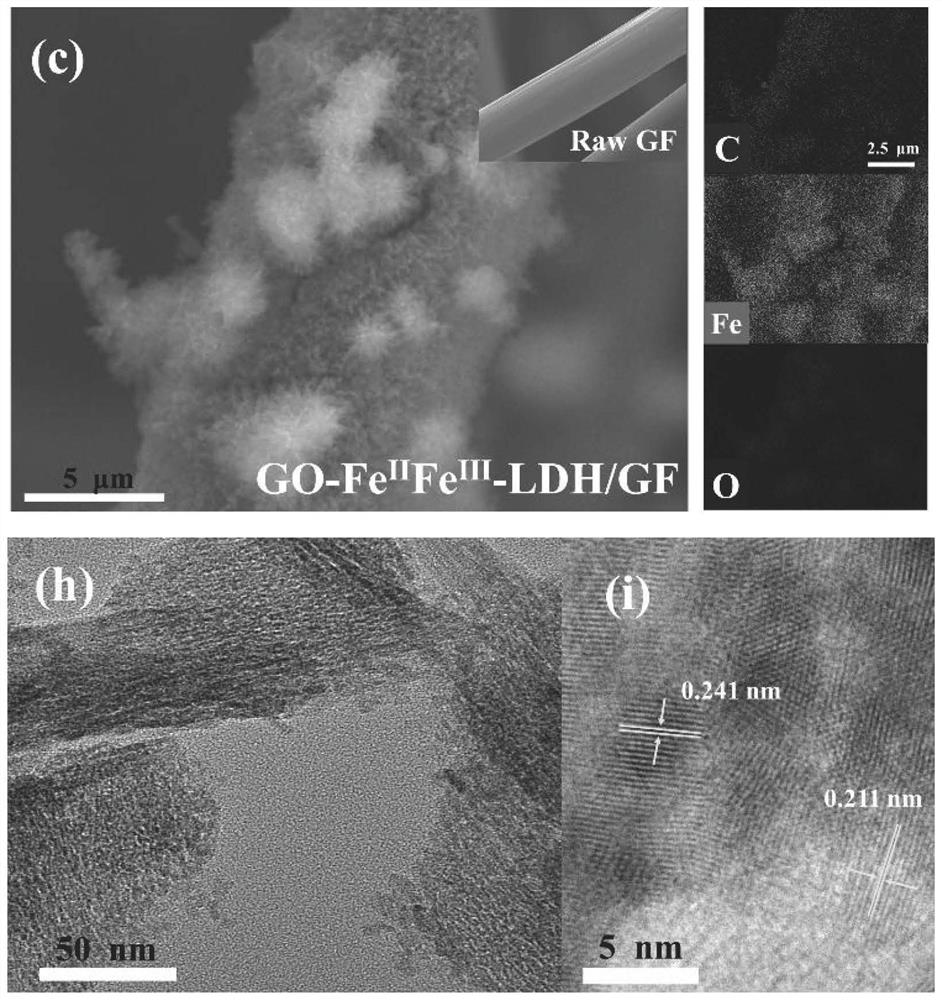

[0032] The invention provides a kind of preparation method of the graphite felt electrode modified by iron-containing graphene oxide, comprising the following steps:

[0033] (1) immerse graphite felt in concentrated nitric acid and heat to obtain modified graphite felt;

[0034] (2) Fe(NO 3 ) 3 , FeSO 4 , The pore forming agent is dissolved in the graphene oxide solution to obtain a growth solution;

[0035] (3) placing the modified graphite felt in a growth solution for heat treatment to obtain a graphite felt electrode modified with iron-containing graphene oxide.

[0036]In the present invention, the graphite felt is washed and dried before being immersed in concentrated nitric acid. The washing is continuous ultrasonication in ethanol for 13 to 18 minutes, followed by water cleaning for 3 to 4 times, preferably continuous ultrasonication in ethanol for 14 to 4 minutes. 16 minutes, and then washed 3 times with water; the drying is drying in air at 55-65° C. for 10-14 h...

Embodiment 1

[0048] A preparation method for a graphite felt electrode modified with iron-containing graphene oxide, comprising the following steps:

[0049] (1) The electrode was prepared on the basis of graphite felt (160mm×45mm), and the preparation process was carried out in a reactor (effective volume: 450mL). Continuously ultrasonicate the graphite felt in ethanol for 13 minutes, wash it with water for 3 times, and then dry it in the air at 58°C for 11h, then immerse the dried graphite felt in concentrated nitric acid and heat it in a water bath at 98°C for 0.9h to obtain the modified graphite felt;

[0050] (2) After graphene oxide is placed in deionized water for ultrasonic dispersion, sodium dodecylbenzenesulfonate is added to obtain a graphene oxide solution, wherein the concentration of graphene oxide is 1g / L, and the concentration of sodium dodecylbenzenesulfonate Concentration is 0.5g / L, then Fe(NO 3 ) 3 , FeSO 4 1. Urea is dissolved in the graphene oxide solution to obtai...

Embodiment 2

[0053] (1) The electrode was prepared on the basis of graphite felt (160mm×45mm), and the preparation process was carried out in a reactor (effective volume: 450mL). Continuously ultrasonicate the graphite felt in ethanol for 16 minutes, wash it with water for 3 times, and then dry it in the air at 65°C for 14h, then immerse the dried graphite felt in concentrated nitric acid and heat it in a water bath at 100°C for 1.2h to obtain the modified graphite felt;

[0054] (2) After graphene oxide is placed in deionized water for ultrasonic dispersion, sodium dodecylbenzenesulfonate is added to obtain a graphene oxide solution, wherein the concentration of graphene oxide is 1.1g / L, sodium dodecylbenzenesulfonate The concentration is 0.5g / L, then Fe(NO 3 ) 3 , FeSO 4 , (NH 4 ) 2 CO 3 According to the ratio of 0.08:0.14:1, the molar ratio is dissolved in the graphene oxide solution to obtain the growth solution, graphene oxide and (NH 4 ) 2 CO 3 The molar ratio of mass is 1.1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com