Rotary pressure reaction furnace

A pressure reaction, rotary technology, applied in the field of pressure vessel equipment, can solve the problems of inability to meet high pressure environment, no explosion-proof measures, no clear reactor pressure, etc., and achieve the effect of shortening manual operation time, shortening production cycle and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

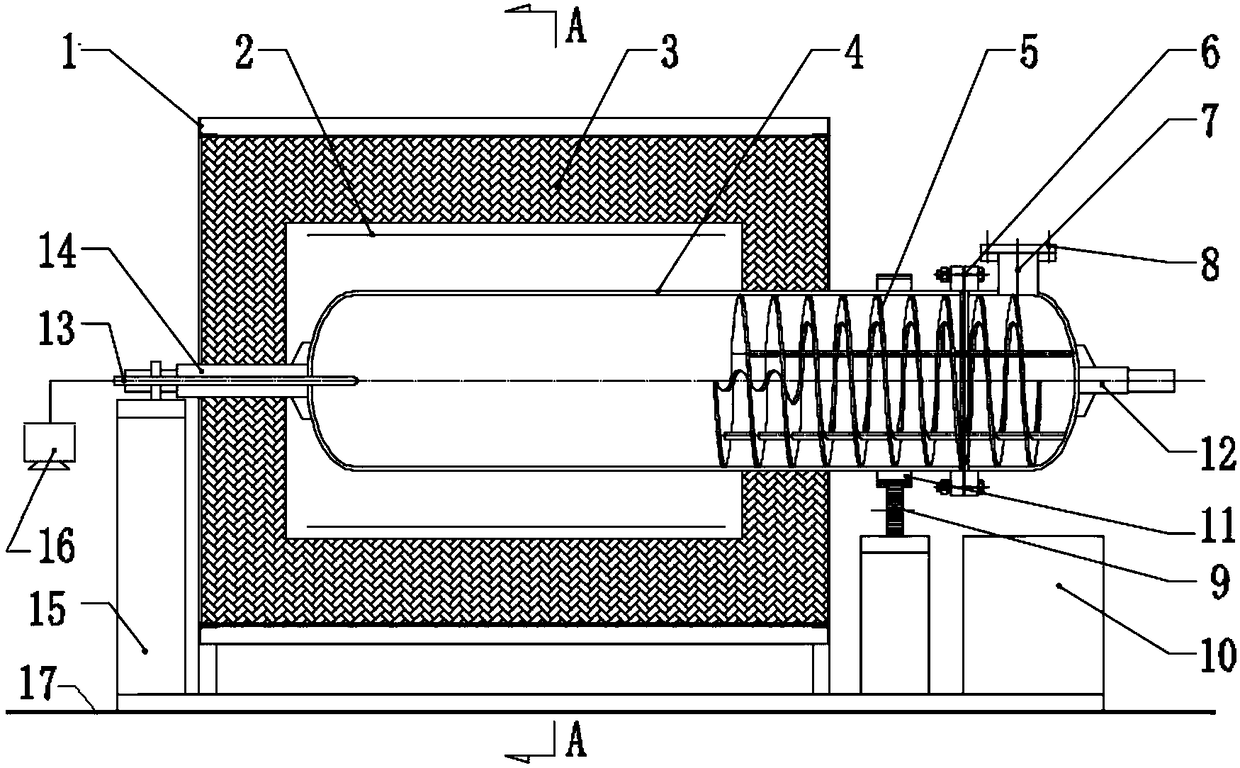

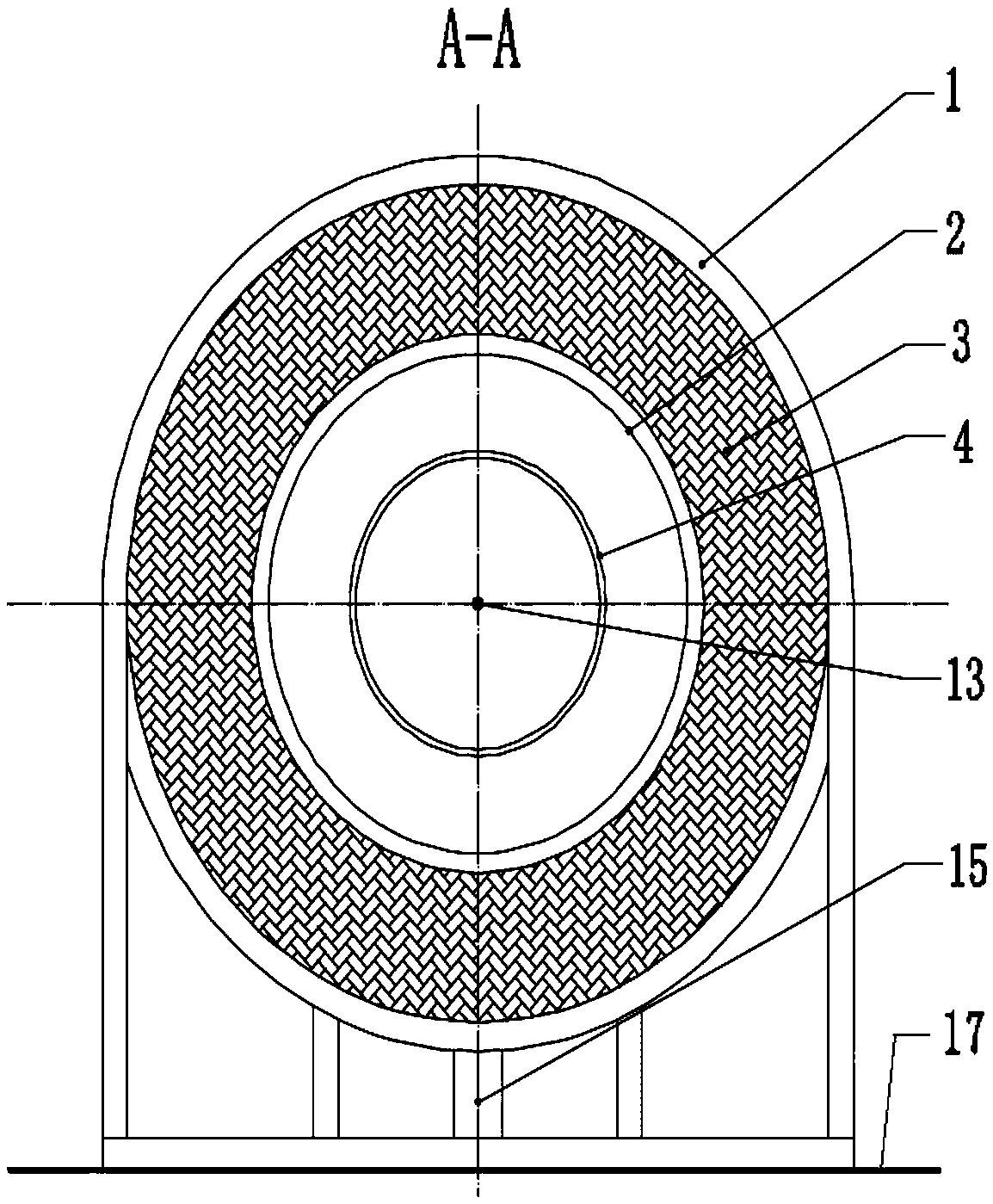

[0024] Embodiment 1: the present invention provides a kind of rotary pressure reaction furnace, its structure is as figure 1 , figure 2 As shown in the figure, it can be seen that the rotary pressure reaction furnace includes at least a heating furnace and a reactor 4. The heating furnace is fixed on the foundation 17 through a furnace steel structure 1. The furnace steel structure of the heating furnace is cylindrical, round A furnace body refractory material layer 3 is built inside the cylinder, and the heating device 2 is installed on the axial inner wall of the furnace body refractory material layer, so that the annular heat source of the heating device surrounds the reactor; Device 5, maintenance flange 6, material inlet and outlet 7, explosion-proof device 8, transmission device 9, transmission rack 11, gas inlet and extraction device 12, detection device 13 and control system 16, and a hopper 10 is also provided.

[0025] The reactor 4 is a long cylinder with both end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com