Explosion-proof and self-cleaning artificial quartz plate and preparation method thereof

A quartz slate, self-cleaning technology, applied in the field of artificial quartz stone, can solve the problems of insufficiency of fouling, no antibacterial properties, and easy breakage of artificial quartz slate, and achieves long service life, good structural stability, and good redox ability. and photostability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

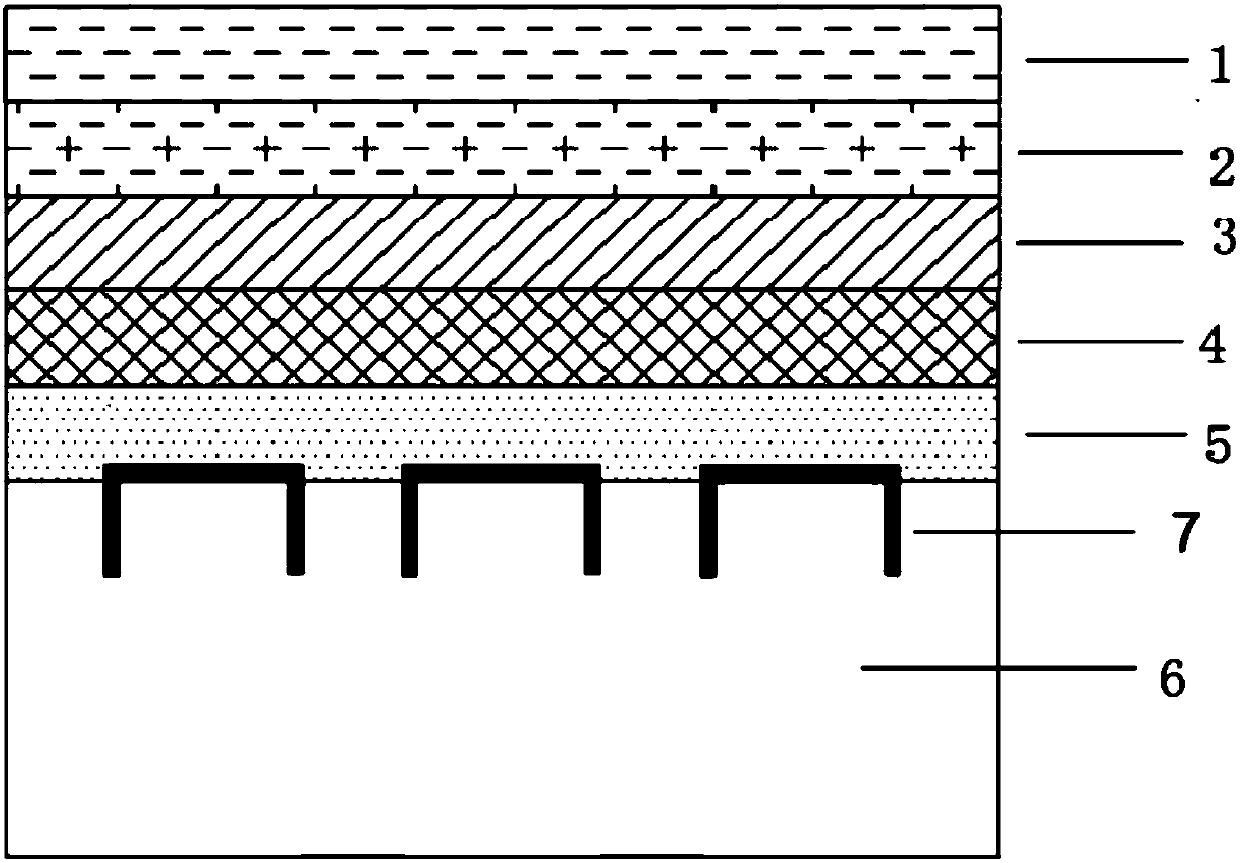

[0043] An explosion-proof, self-cleaning artificial quartz slab of this embodiment includes a self-cleaning layer 1, an antibacterial layer 2, a refractory layer 3, a buffer layer 4, an explosion-proof layer 5, and a base layer 6, and the base layer 6 is provided with an explosion-proof layer 5. The explosion-proof layer 5 is provided with a buffer layer 4, the buffer layer 4 is provided with a refractory layer 3, the refractory layer 3 is provided with an antibacterial layer 2, and the antibacterial layer 2 is provided with a self-cleaning layer 1, and the base layer 6 and several fixing parts 7 are arranged in the explosion-proof layer 5; as figure 1 ;

[0044] The thickness of the self-cleaning layer 1 is 1 mm, the thickness of the antibacterial layer is 1 mm, the thickness of the refractory layer is 4 mm, the thickness of the explosion-proof layer is 3 mm, and the thickness of the base layer is 1 cm.

[0045] The raw material components of the self-cleaning layer 1: 30 pa...

Embodiment 2

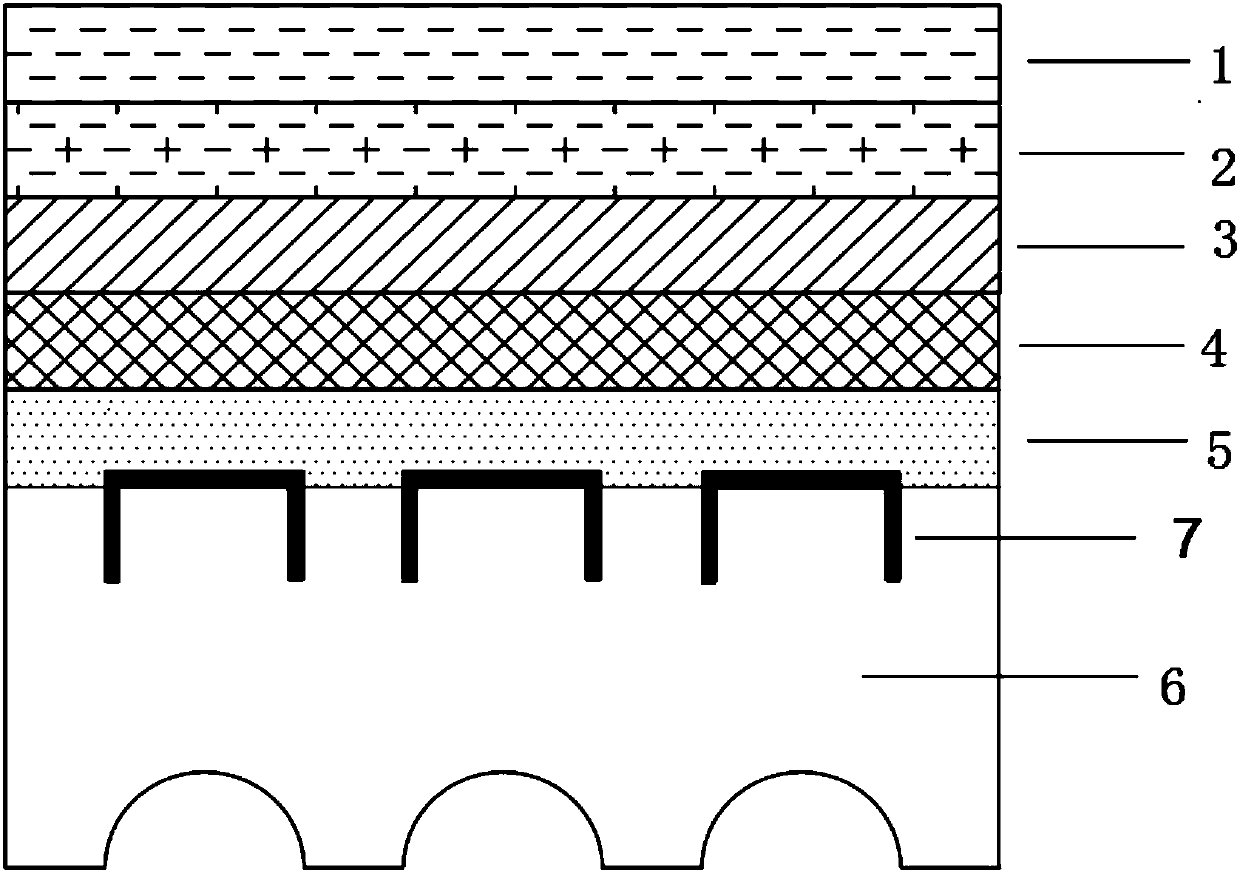

[0063] An explosion-proof, self-cleaning artificial quartz slab of this embodiment includes a self-cleaning layer 1, an antibacterial layer 2, a refractory layer 3, a buffer layer 4, an explosion-proof layer 5, and a base layer 6, and the base layer 6 is provided with an explosion-proof layer 5. The explosion-proof layer 5 is provided with a buffer layer 4, the buffer layer 4 is provided with a refractory layer 3, the refractory layer 3 is provided with an antibacterial layer 2, and the antibacterial layer 2 is provided with a self-cleaning layer 1, and the base layer 6 and several fixing parts 7 are arranged in the explosion-proof layer 5;

[0064] The bottom of the plate body of the base layer 6 is also provided with several through holes arranged along the length direction, and the cross section of the through holes is semicircular: as figure 2 ;

[0065] The thickness of the self-cleaning layer 1 is 2 mm, the thickness of the antibacterial layer 2 is 2 mm, the thickness ...

Embodiment 3

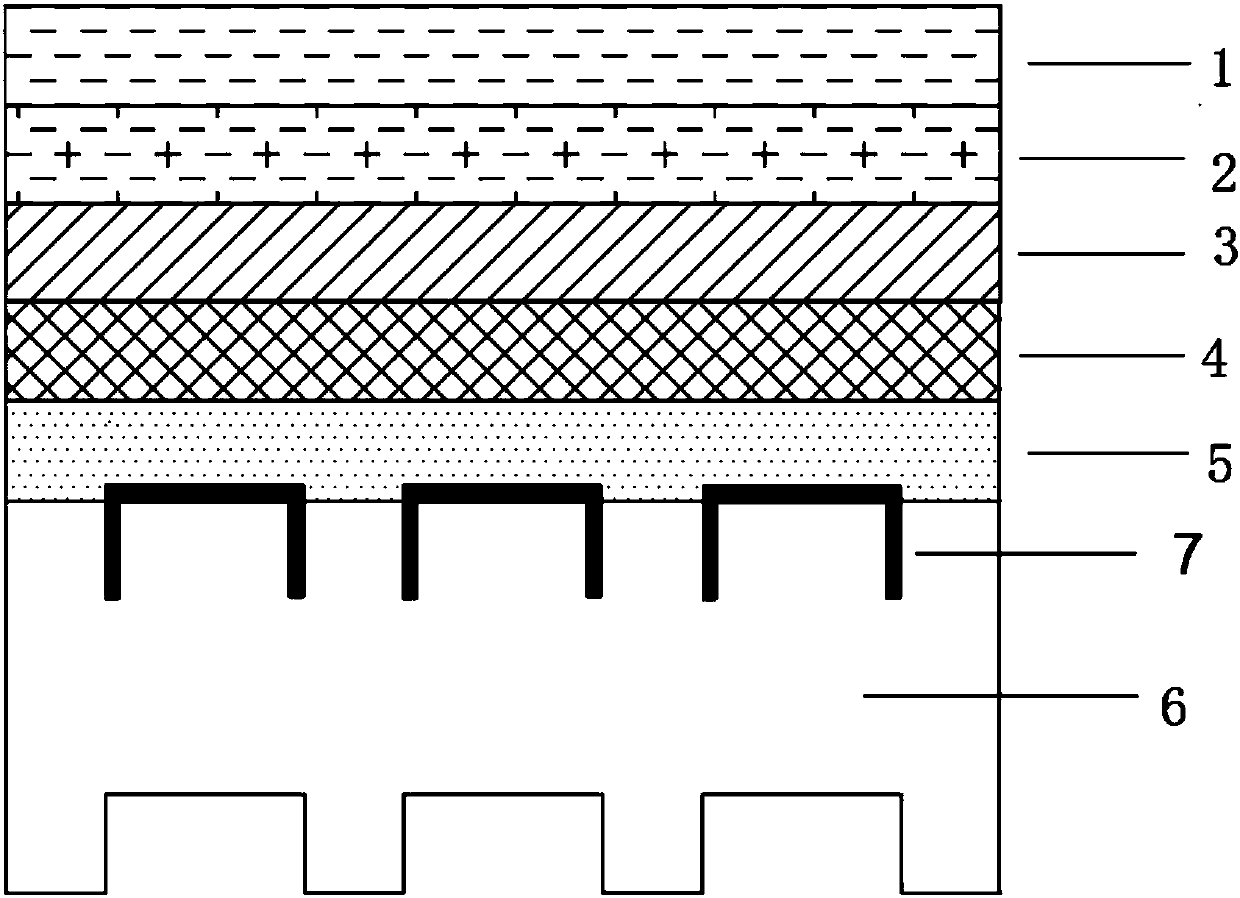

[0084] An explosion-proof, self-cleaning artificial quartz slab of this embodiment includes a self-cleaning layer 1, an antibacterial layer 2, a refractory layer 3, a buffer layer 4, an explosion-proof layer 5, and a base layer 6, and the base layer 6 is provided with an explosion-proof layer 5. The explosion-proof layer 5 is provided with a buffer layer 4, the buffer layer 4 is provided with a refractory layer 3, the refractory layer 3 is provided with an antibacterial layer 2, and the antibacterial layer 2 is provided with a self-cleaning layer 1, and the base layer 6 and several fixing parts 7 are arranged in the explosion-proof layer 5;

[0085] The bottom of the plate body of the base layer 6 is also provided with several through holes arranged along the length direction, and the cross section of the through holes is rectangular; image 3 ;

[0086] The thickness of the self-cleaning layer 1 is 3 mm, the thickness of the antibacterial layer 2 is 5 mm, the thickness of th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com