Transportation equipment convenient for transferring silicon cutting slag

A transportation equipment, silicon cutting technology, applied in solid separation, sieve, grid, etc., can solve the problem that the hopper cannot classify and transport silicon materials and silicon slag of different sizes, and cannot screen and screen silicon materials and silicon slag, Recycle silicon material and silicon slag to achieve the effect of improving service life, reducing wear and protecting the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

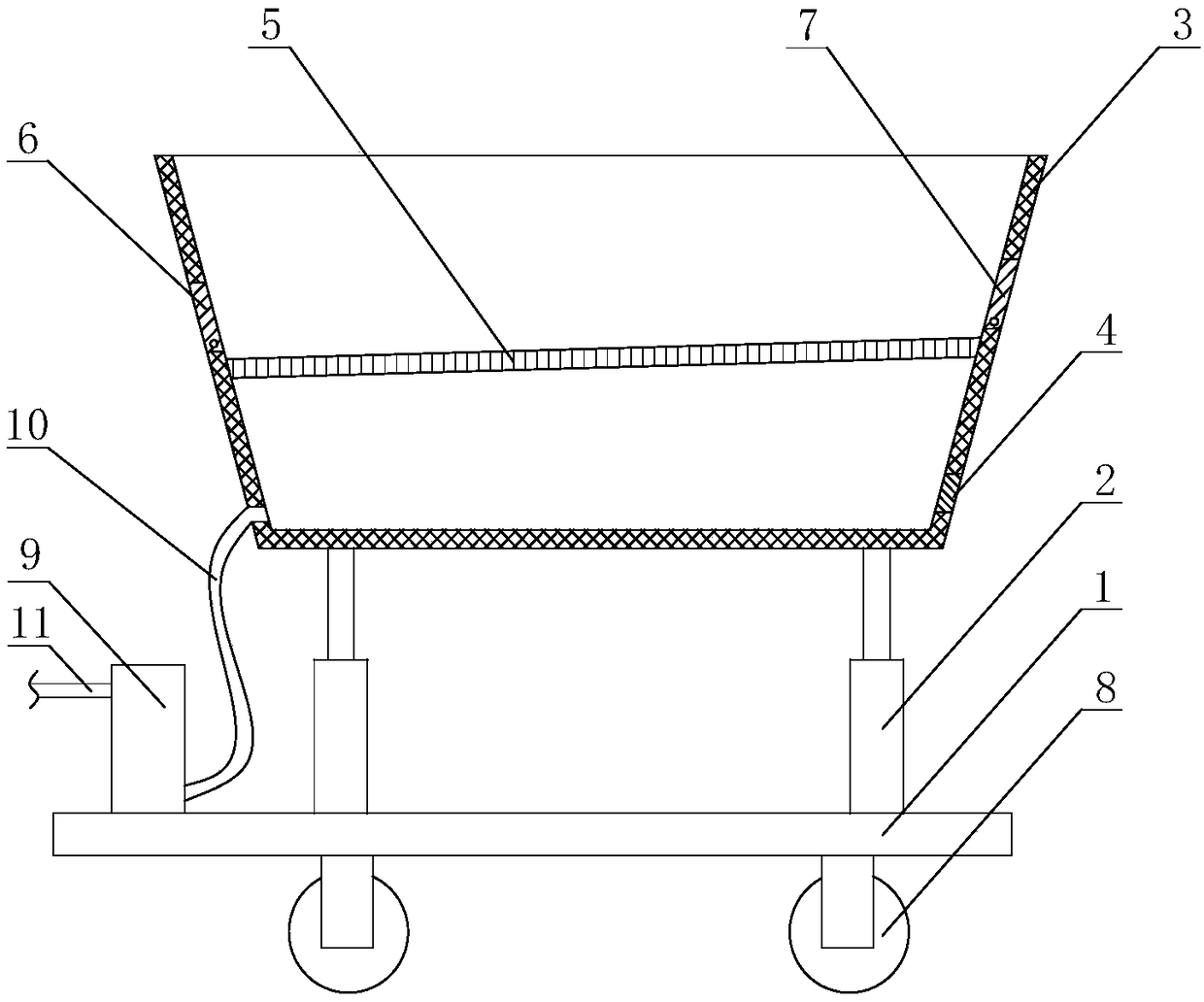

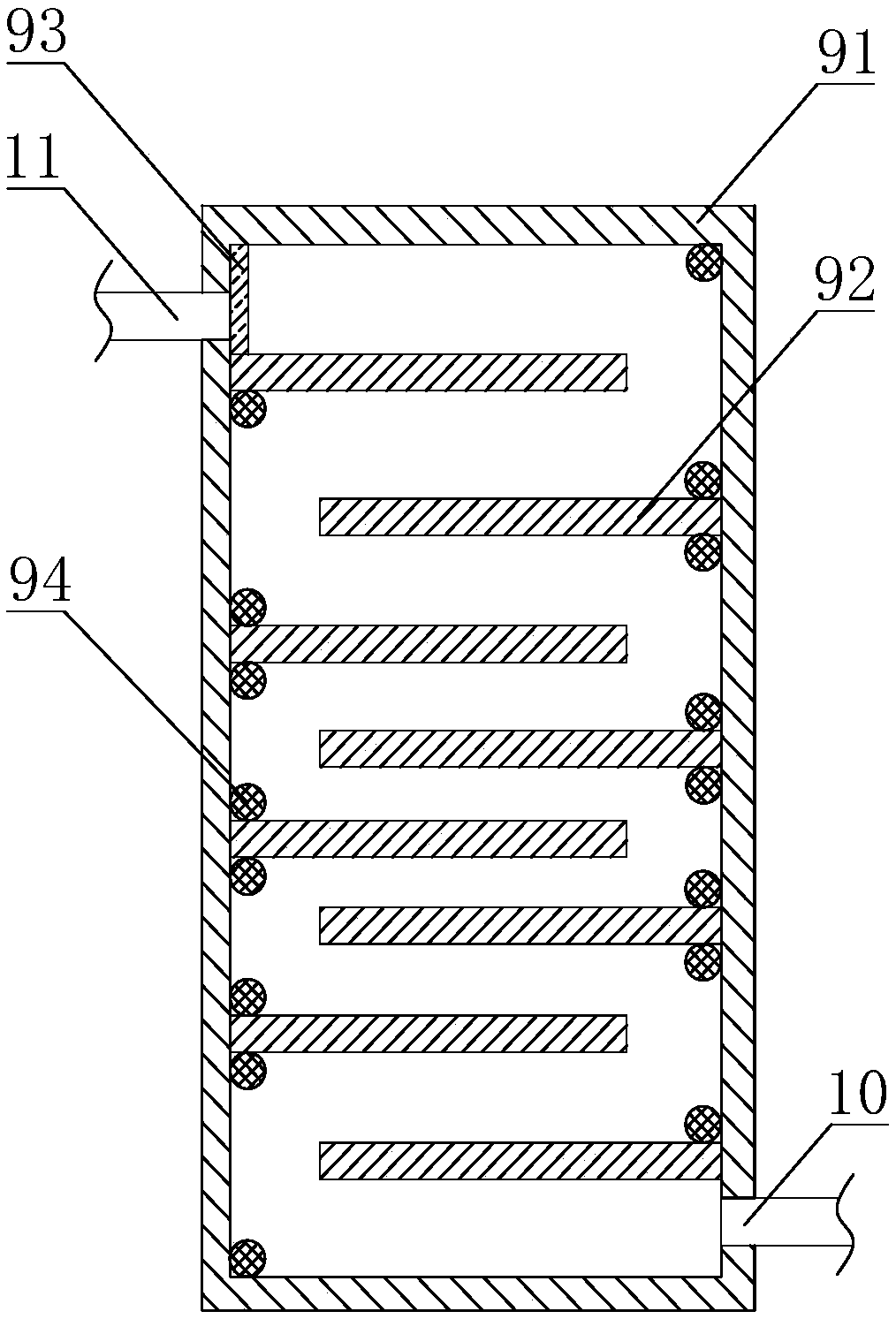

[0039] Such as figure 1 and figure 2 The transportation equipment shown is convenient for the transfer of silicon cutting slag, including a base 1, the bottom of the base 1 is provided with a universal wheel 8, the base 1 is provided with a hydraulic cylinder 2, and the top end of the piston rod of the hydraulic cylinder 2 is fixedly connected There is a sieve hopper 3, the sieve plate 5 is arranged in the sieve hopper 3, the wall surface of the sieve hopper 3 is provided with a feed port and a discharge port located above the sieve plate 5, and a feed plate 7 is arranged in the feed port , a discharge plate 6 is arranged in the discharge opening, and a slag inlet and a slag discharge outlet located below the sieve plate 5 are also arranged on the wall surface of the sieve hopper 3, and a slag inlet plate 4 is arranged in the slag inlet, and the slag outlet passes The slag pipe 10 is connected with a filter box 9, the filter box 9 includes a housing 91, the casing 91 is prov...

Embodiment 2

[0043] Such as figure 1 As shown, on the basis of Embodiment 1, the feed plate 7 is hinged in the feed port, the discharge plate 6 is hinged in the discharge port, and the slag feed plate 4 is hinged in the slag feed port; the sieve plate 5 is close to One end of the feed plate 7 is higher than the end of the sieve plate 5 close to the discharge plate 6; the angle between the sieve plate 5 and the horizontal plane is 5-15°; the aperture of the sieve plate 5 is 1.2mm.

[0044] When loading, adjust the height of the sieve hopper 3 through the hydraulic cylinder 2, open the feed plate 7 to feed silicon material above the sieve plate 5, then adjust the height of the sieve hopper 3, open the slag feed plate 4 to feed silicon slag under the sieve plate 5 . After the feeding is completed, push the base 1 to move to move the silicon material and silicon slag to the designated place. During the moving process, part of the silicon slag breaks away from the silicon material during the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com