Granulation machine for casting smelting molten iron of iron alloy series products into granular products

A series of products, iron alloy technology, applied in the direction of feeding molten metal into molds, casting equipment, metal processing equipment, etc., to achieve the effects of saving labor costs, reducing environmental pollution, and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

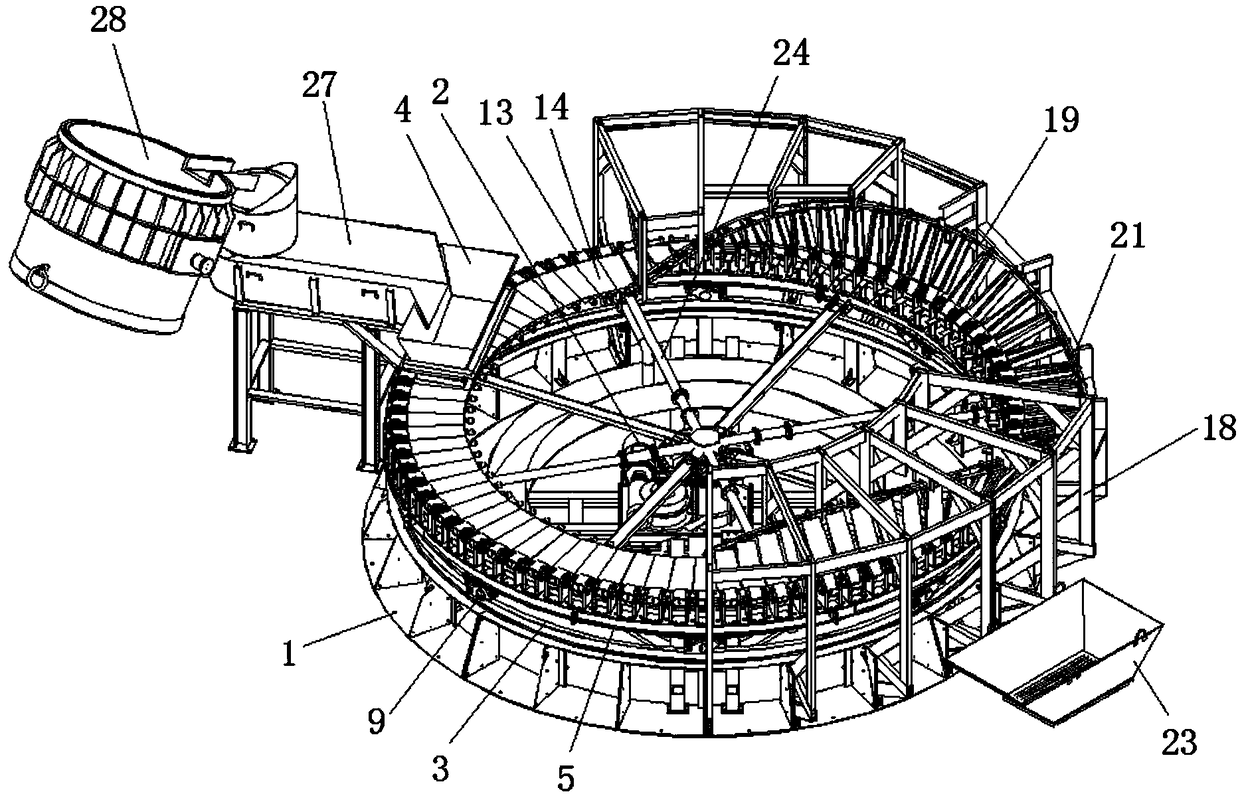

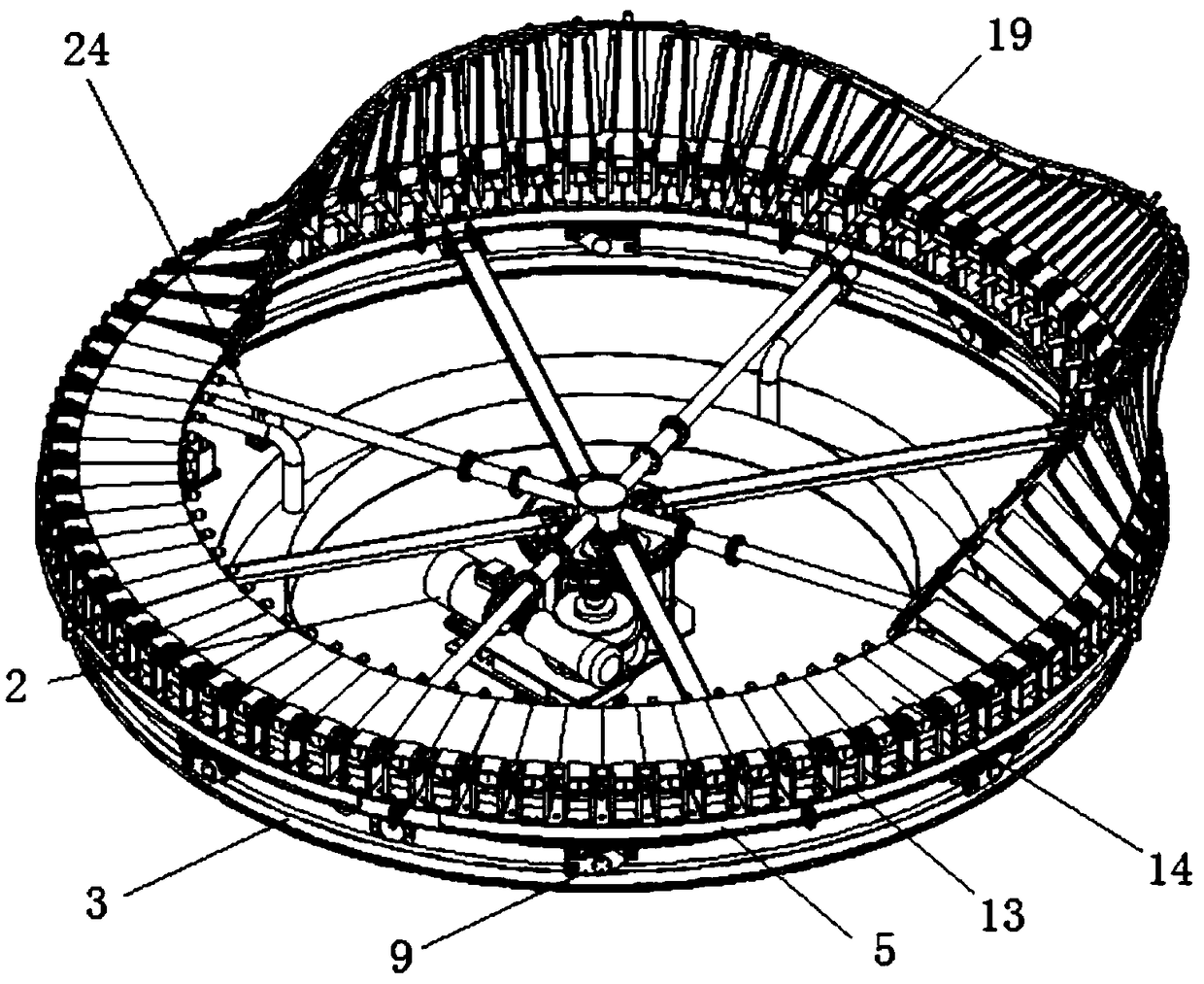

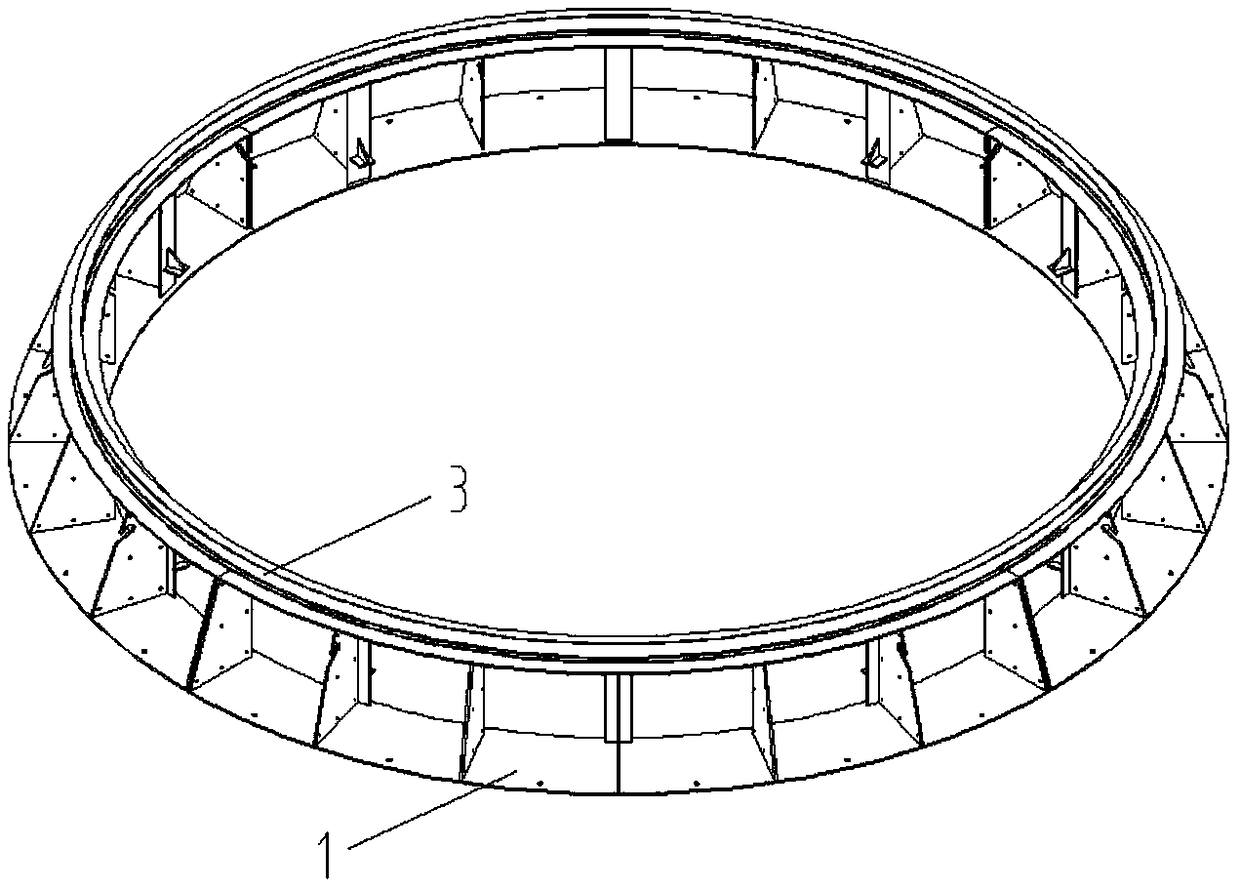

[0038] Such as figure 1 and 2As shown, a granular machine for smelting molten iron and casting ferroalloy series products into granular products, including a base 1, a cooling mechanism, a casting and forming mechanism, a turning and reset mechanism and a central power device 2. Such as image 3 As shown, the base 1 is a circular platform structure, and a circle of rails 3 is arranged on the top thereof. The cooling mechanism is slidably mounted on the track 3, and one end of the casting and forming mechanism is mounted on the cooling mechanism to be rotatable up and down to realize that the other end of the casting and forming mechanism can be carried out relative to the cooling mechanism. Flip the action up and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com