Double-sided down-filling warm and windproof shell fabric and preparation process thereof

A preparation process and down-filled technology, which is applied in the field of double-sided down-filled thermal and windproof fabrics and its preparation technology, can solve the problems of lack of all-round warmth, uneven thickness of down filling, and uneven thickness of fabrics, etc., to achieve warmth retention The effect is uniform, the effect of keeping warm is good, and the preparation process is simple

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

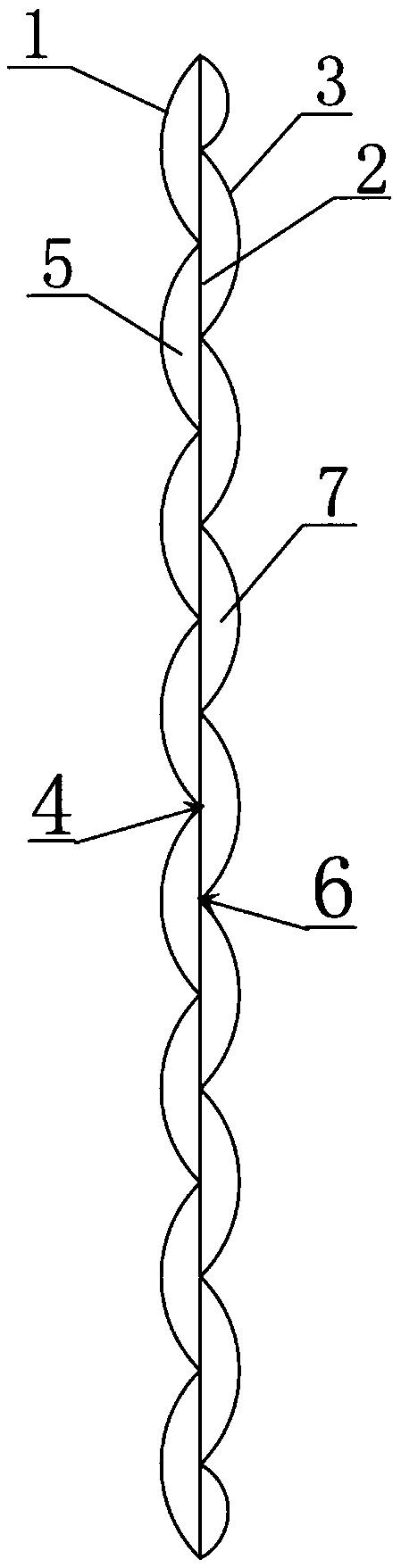

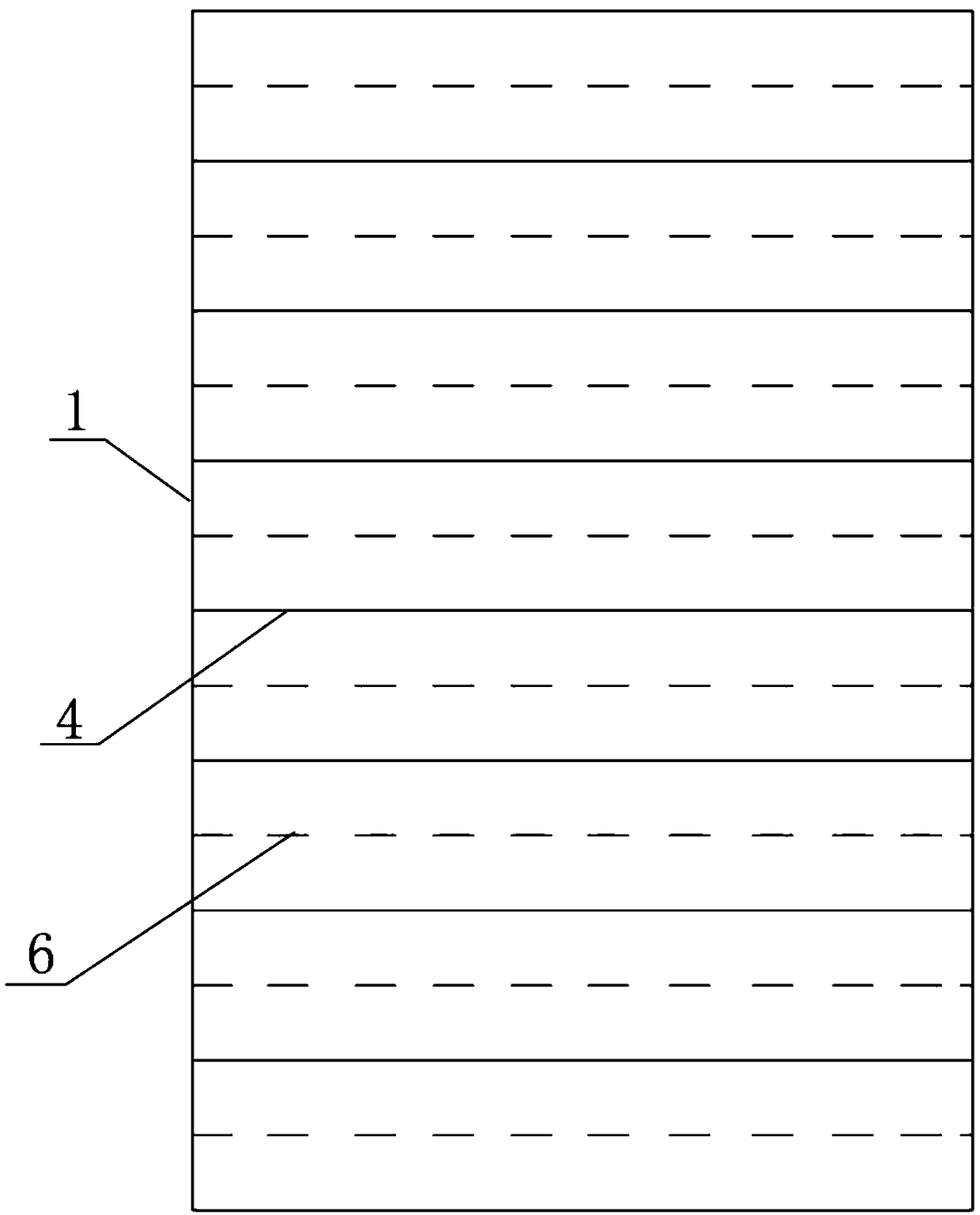

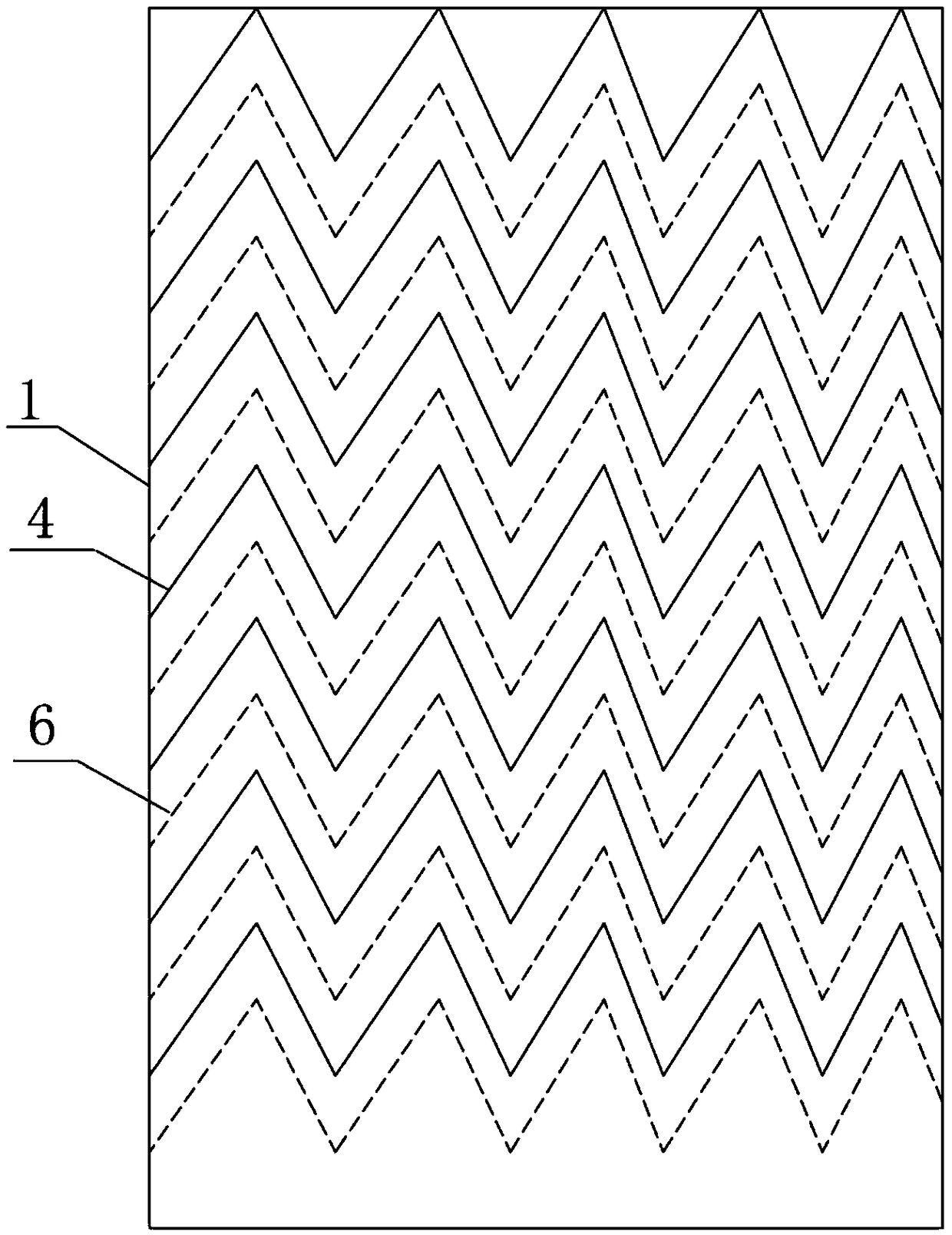

[0031] Such as Figure 1-2 A double-sided cashmere-filled warm and windproof fabric shown includes a surface fabric 1, a connecting fabric 2 and an inner fabric 3, the surface fabric 1, the connecting fabric 2 and the inner fabric 3 are arranged sequentially from the outside to the inside, and the surface fabric 1. Both the connecting fabric 2 and the inner fabric 3 are made of 20D matt and anti-velvet fabric, which reduces the weight of the clothes and makes cleaning more convenient; the surface fabric 1 and the connecting fabric 2 are connected together by a plurality of first connecting lines 4 , and a plurality of first filling cavities 5 are formed between the surface fabric 1 and the connecting fabric 2; the connecting fabric 2 and the inner fabric 3 are connected together by a plurality of second connecting lines 6, and the connecting fabric 2 and the inner fabric 3 are connected together. A plurality of second filling cavities 7 are formed between the inner fabrics 3; ...

Embodiment 2

[0038] The preparation process of a kind of double-sided cashmere-filled warm and windproof fabric described in Example 1 comprises the following steps:

[0039] Cut the surface fabric 1, the connecting fabric 2 and the inner fabric 3 according to the requirements, set aside, align and sew the upper ends of the surface fabric 1, the connecting fabric 2 and the inner fabric 3;

[0040] According to the design spacing, the surface layer fabric 1 and the connecting fabric 2 are connected together through a plurality of first connecting lines 4, and a plurality of first filling cavities 5 are formed between the surface layer fabric 1 and the connecting fabric 2; The layers of fabrics 3 are connected together by a plurality of second connecting lines 6, and a plurality of second filling cavities 7 are formed between the connecting fabrics 2 and the inner layer of fabrics 3; the first connecting lines 4 and the second connecting lines 6 are in the form of Arranged in a staggered man...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com