Anhydrous glucose preparation process

A technology for the preparation of anhydrous glucose, which is applied in the preparation of sugar derivatives, monosaccharides, sugar derivatives, etc., can solve the problems affecting the solubility of particles, and achieve the effect of improving the purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

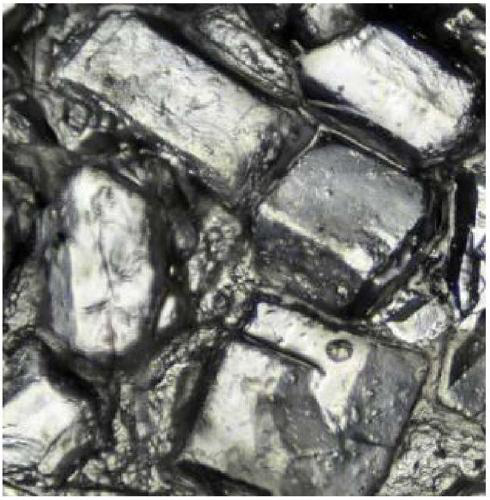

Image

Examples

Embodiment 1

[0030] 1) Decolorization and filtration: 1.5 t of mother liquor separated from the production of glucose monohydrate, with a glucose purity of 80%, is decolorized by activated carbon at 80° C. and pH 4.3, and the decolorization time is set at 25 minutes. Take the method of decolorization in stages, and decolorize with used activated carbon for 10 minutes before decolorization, and decolorize with new activated carbon for 25 minutes after decolorization. First pass through weakly acidic cation exchange resin, and then pass through three groups of weakly basic anion exchange resins (in turn through three groups of yang and yin, yang and yin, and yang and yin) to remove inorganic salts and organic impurities, and filter to obtain glucose with a purity of 82.5%. Liquid 1.3t.

[0031] 2) Crystallization: The filtered glucose liquid enters the crystallization tank, adopts a vacuum boiling sugar tank (without special modification), and stably controls the vacuum degree at 0.85×10 5 ...

Embodiment 2

[0037] 1) Decolorization and filtration: 1.5 t of mother liquor separated from the production of glucose monohydrate, with a glucose purity of 80.7%, is decolorized by activated carbon at 80° C. and pH 4.3, and the decolorization time is set at 25 minutes. Take the method of decolorization in stages, and decolorize with used activated carbon for 10 minutes before decolorization, and decolorize with new activated carbon for 25 minutes after decolorization. First pass through weakly acidic cation exchange resins, and then pass through three groups of weakly basic anion exchange resins (three groups, which are followed by positive and negative, positive and negative, positive and negative three groups), to remove inorganic salts and organic impurities, and filter to obtain a purity of 81.8% glucose solution 1.31t.

[0038] 2) Crystallization: The filtered glucose liquid enters the crystallization tank, adopts a vacuum boiling sugar tank (without special modification), and stably ...

Embodiment 3

[0044] 1) Decolorization and filtration: 1.5 t of mother liquor separated from the production of glucose monohydrate, with a glucose purity of 80%, is decolorized by activated carbon at 80° C. and pH 4.3, and the decolorization time is set at 25 minutes. Take the method of decolorization in stages, and decolorize with used activated carbon for 10 minutes before decolorization, and decolorize with new activated carbon for 25 minutes after decolorization. First pass through weakly acidic cation exchange resins, and then pass through three groups of weakly basic anion exchange resins (three groups, which are followed by positive and negative, positive and negative, positive and negative three groups), to remove inorganic salts and organic impurities, and filter to obtain a purity of 82.4% glucose solution 1.3t.

[0045]2) Crystallization: The filtered glucose liquid enters the crystallization tank, adopts a vacuum boiling sugar tank (without special modification), and stably cont...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com