Modified polyacrylate dispersion solution

A technology of polyacrylate and acrylate, which is applied in the field of modified polyacrylate dispersion, and can solve problems such as poor processing continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0040] The preparation method of the modified polyacrylate dispersion of the present application can be obtained by emulsion polymerization or solution copolymerization. Preferably, emulsion polymerization is used.

[0041] For example, when it does not contain crosslinking monomer units, other acrylate monomer units other than the aforementioned acrylate type, and / or non-crosslinking non-acrylate type double bond-containing monomer units, the monomer is defined as an acrylate monomer. When containing cross-linking monomer units, other acrylate monomer units other than the aforementioned acrylate type and / or non-cross-linking non-acrylate type double-bond-containing monomer units, the acrylate monomer and cross-linking monomer units, non- Other acrylate monomer units of the aforementioned acrylate type and / or non-crosslinking non-acrylate type double bond-containing monomer units are collectively referred to as monomers.

[0042] In one embodiment, the preparation process of ...

Embodiment 1

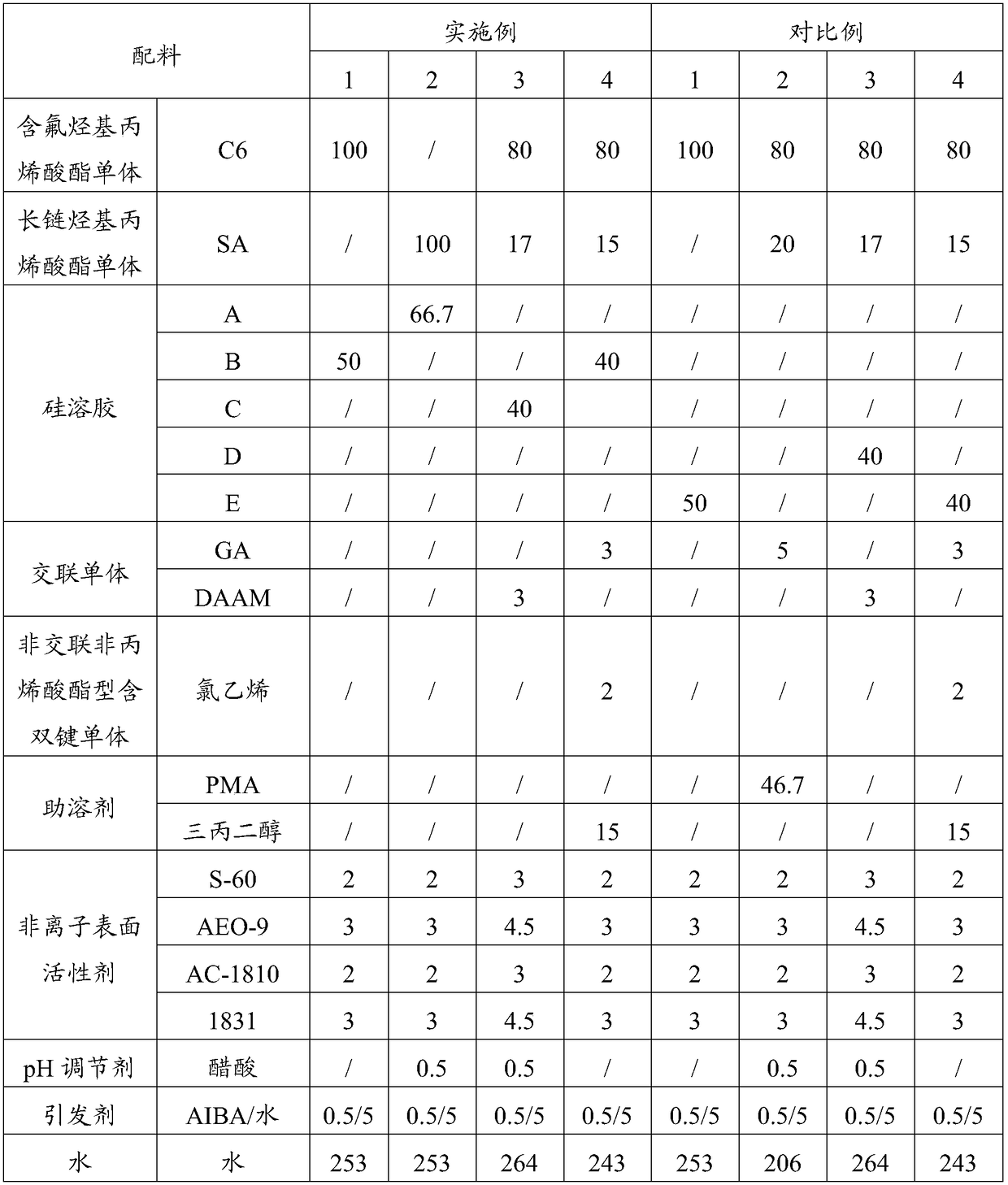

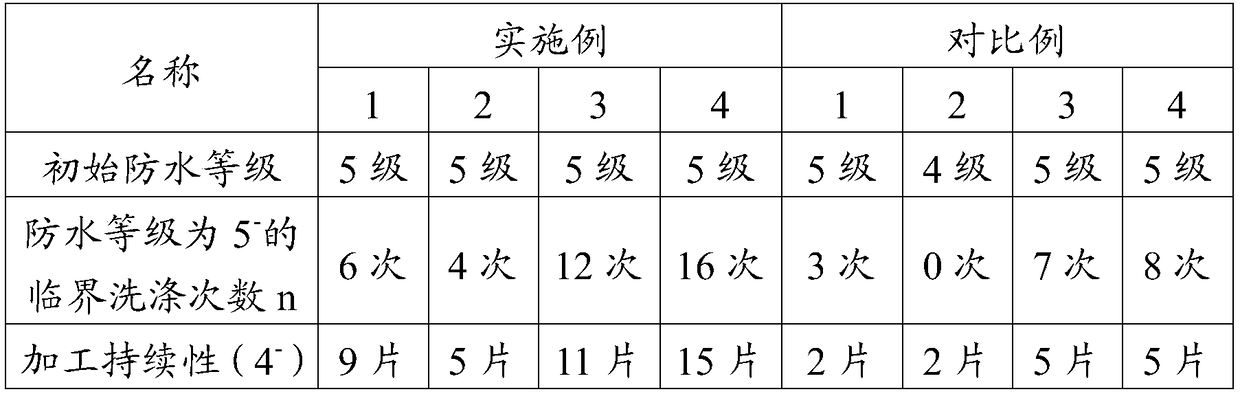

[0067] Add 100 parts by mass of C6, 50 parts by mass of silica sol B, 2 parts by mass of S-60, 3 parts by mass of AEO-9, 2 parts by mass of AC-1810, 3 parts by mass of 1831 and 253 parts by mass of water into the reactor, and heat up to Pre-emulsification is carried out at 40-45°C. Then homogenize under high pressure for 30 minutes, transfer the homogenized solution to the reaction kettle, and start stirring. Dissolve 0.5 parts by mass of initiator azobisisobutylamidine hydrochloride (AIBA) into 5 parts by mass of water to form a uniform solution, and add it into the reaction kettle. Then the temperature was raised to 70-75° C. for 5 hours to obtain the hydrophobic silica sol-modified polyacrylate dispersion of the present invention.

[0068] Examples 2-3 and Comparative Examples 1-3 all adopt the same process as Example 1, and the specific formulations are shown in Table 2. That is to say, add the ingredients other than the initiator into the reactor, and raise the temperat...

Embodiment 4

[0070] 80 parts by mass of C6, 40 parts by mass of silica sol B, 15 parts by mass of SA, 3 parts by mass of GA, 15 parts by mass of tripropylene glycol, 2 parts by mass of S-60, 3 parts by mass of AEO-9, 2 parts by mass of AC-1810 , 3 parts by mass of 1831 and 238 parts by mass of water were added to the reactor, and the temperature was raised to 40-45°C for pre-emulsification. Then homogenize under high pressure for 30 minutes, transfer the homogenized solution to the reaction kettle, and start stirring. Dissolve 0.5 parts by mass of initiator AIBA into 5 parts by mass of water to form a uniform solution, and add it to the reaction kettle. Then the temperature was raised to 65° C. to start the timing reaction, and 2 parts by mass of vinyl chloride were introduced within 1 hour after the reaction started. The temperature was raised to 70-75° C. to continue the polymerization reaction for 5 hours to obtain the hydrophobic silica sol-modified polyacrylate dispersion of the pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com