Ultraviolet radiation cured pearl gold ink for cigarette brand, and preparation method thereof

A radiation curing, ultraviolet technology, applied in the field of printing ink, can solve the problems of becoming waste, easy oxidation, short product shelf life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

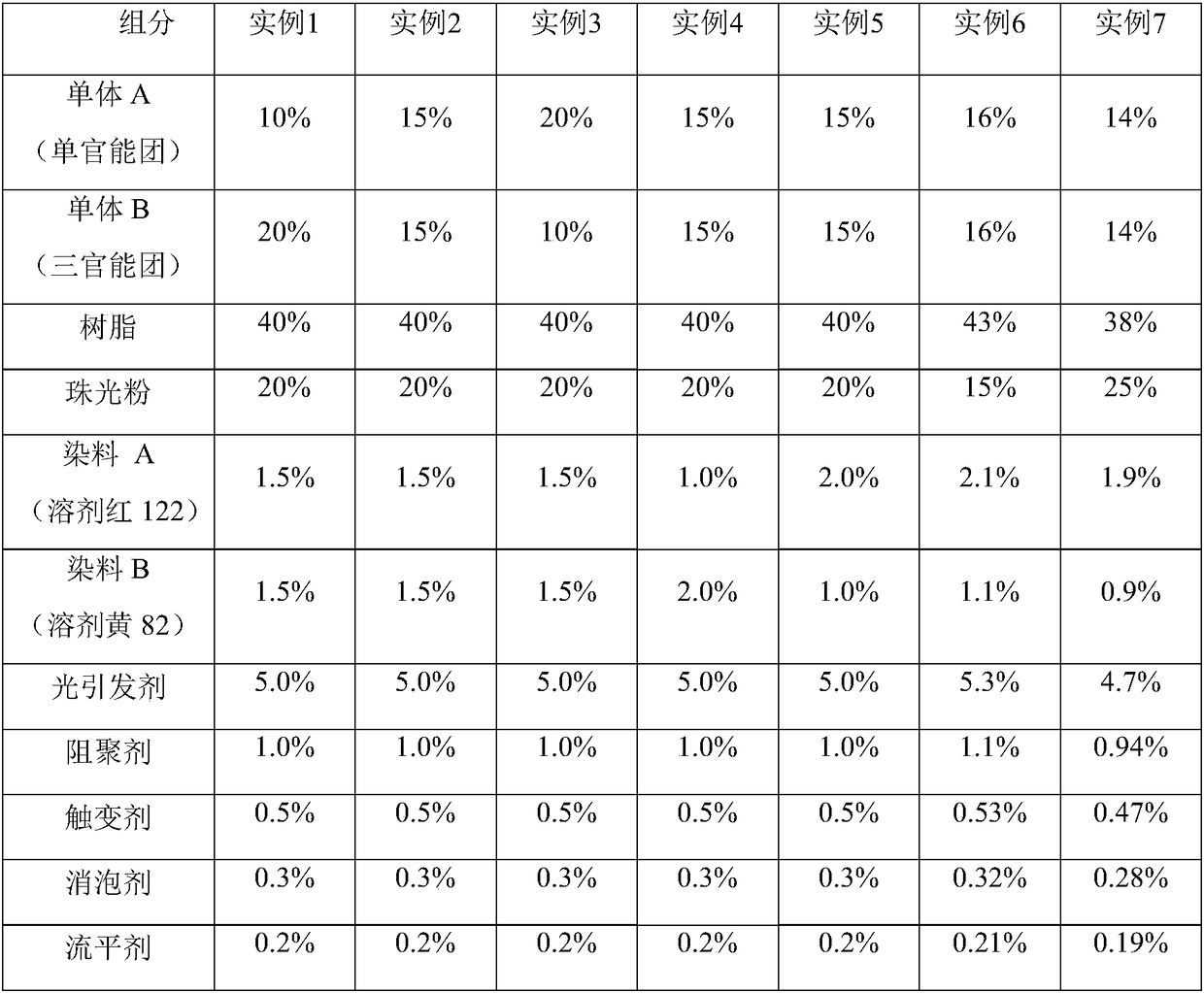

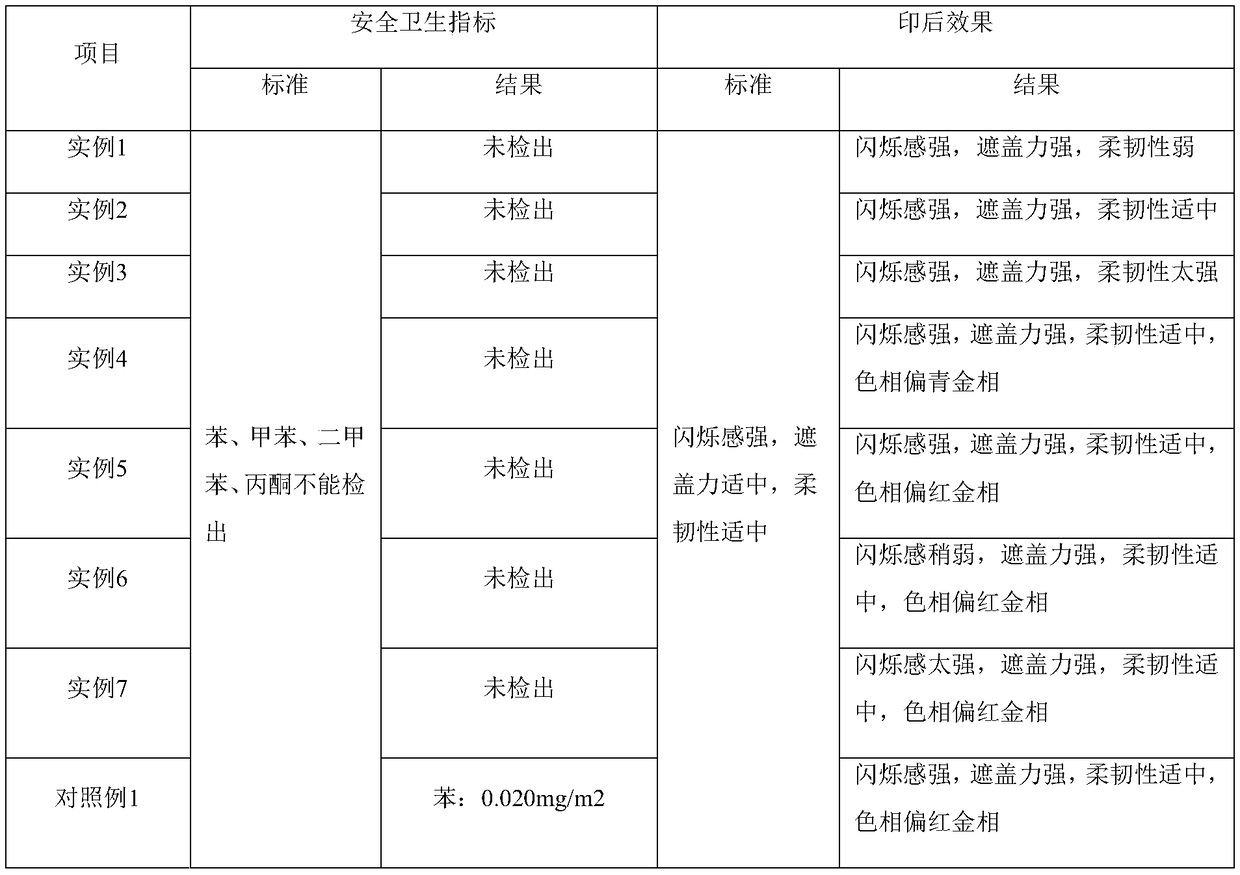

Embodiment 1

[0050] The embodiment of the present invention provides an ultraviolet radiation curable pearlescent gold ink for cigarette labels, which includes the following raw materials in parts by weight: 10% monomer A, 20% monomer B, 40% resin, 20% pearlescent powder, 1.5% dye A , 1.5% dye B, 5% photoinitiator, 1% polymerization inhibitor, 0.5% thixotropic agent, 0.3% defoamer, 0.2% leveling agent.

[0051] Wherein, monomer A is tetrahydrofurfuryl acrylate, monomer B is 3 (ethoxy) trimethylolpropane triacrylate; resin is polyurethane resin; pearl powder is a mixture of mica and titanium dioxide; dye A is C.I. Solvent red 122, dye B is C.I. solvent yellow 82, photoinitiator is biphenyl-m-ethylbenzophenone; polymerization inhibitor is nitroxide free radical piperidinol; thixotropic agent is fumed silica; defoaming The agent is modified polysiloxane; the leveling agent is polysiloxane-polyether copolymer.

[0052] The preparation method of the ultraviolet radiation curing pearlescent gol...

Embodiment 2

[0062] The embodiment of the present invention provides an ultraviolet radiation curable pearlescent gold ink for cigarette labels, comprising the following raw materials in parts by weight: 15% monomer A, 15% monomer B, 40% resin, 20% pearlescent powder, 1.5% dye A , 1.5% dye B, 5% photoinitiator, 1% inhibitor, 0.51% thixotropic agent, 0.3% defoamer, 0.2% leveling agent.

[0063] Wherein, monomer A is tetrahydrofurfuryl acrylate, monomer B is 3 (ethoxy) trimethylolpropane triacrylate; resin is polyurethane resin; pearl powder is a mixture of mica and titanium dioxide; dye A is C.I. Solvent red 122, dye B is C.I. solvent yellow 82, photoinitiator is biphenyl-m-ethylbenzophenone; polymerization inhibitor is nitroxide free radical piperidinol; thixotropic agent is fumed silica; defoaming The agent is modified polysiloxane; the leveling agent is polysiloxane-polyether copolymer.

[0064] The preparation method of the ultraviolet radiation curing pearlescent gold ink described in...

Embodiment 3

[0074] The embodiment of the present invention provides an ultraviolet radiation curable pearlescent gold ink for cigarette labels, which includes the following raw materials in parts by weight: 20% monomer A, 10% monomer B, 40% resin, 20% pearlescent powder, and 1.5% dye A , 1.5% dye B, 5% photoinitiator, 1% inhibitor, 0.51% thixotropic agent, 0.3% defoamer, 0.2% leveling agent.

[0075] Wherein, monomer A is tetrahydrofurfuryl acrylate, monomer B is 3 (ethoxy) trimethylolpropane triacrylate; resin is polyurethane resin; pearl powder is a mixture of mica and titanium dioxide; dye A is C.I. Solvent red 122, dye B is C.I. solvent yellow 82, photoinitiator is biphenyl-m-ethylbenzophenone; polymerization inhibitor is nitroxide free radical piperidinol; thixotropic agent is fumed silica; defoaming The agent is modified polysiloxane; the leveling agent is polysiloxane-polyether copolymer.

[0076] The preparation method of the ultraviolet radiation curing pearlescent gold ink desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com