A kind of water-based coil coating and preparation method thereof

A coiled steel, water-based technology, applied in polyester coatings, anti-corrosion coatings, epoxy resin coatings, etc., can solve the problems affecting the post-processing performance of coiled materials, and the T-bending performance of water-based coatings is not up to standard.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0048] The preparation method of the coating of embodiment 1-6, comprises the following steps:

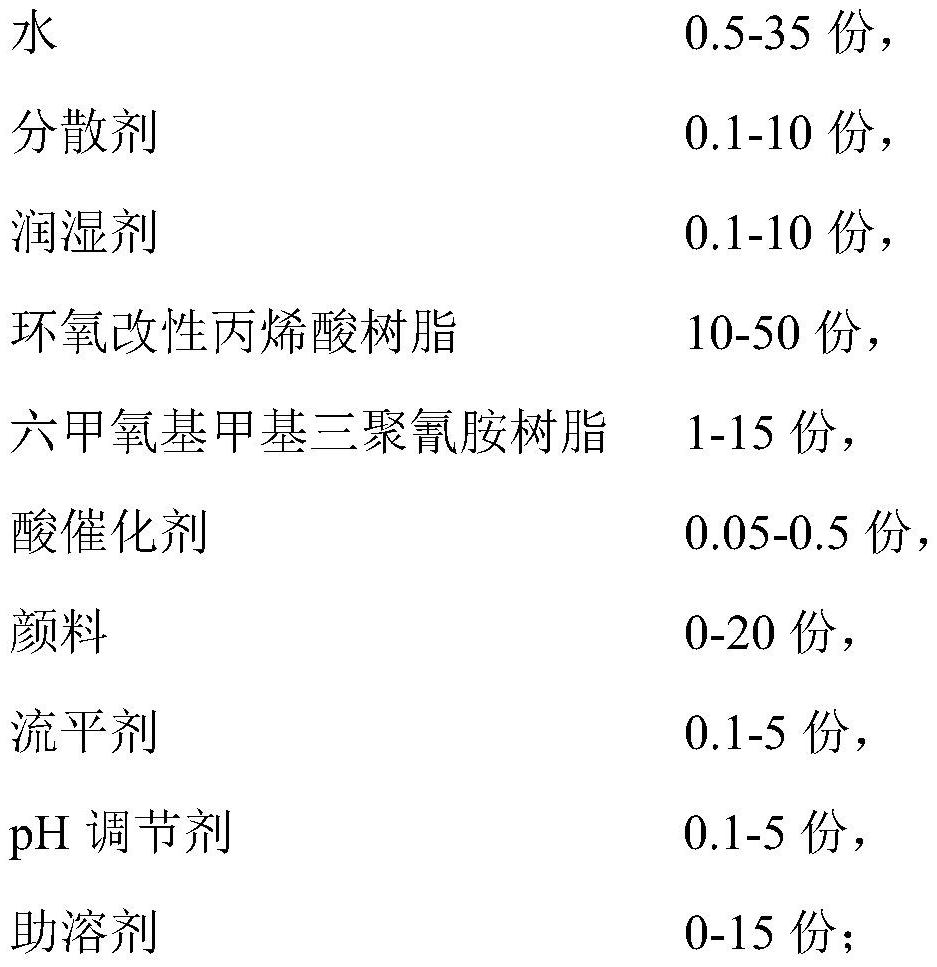

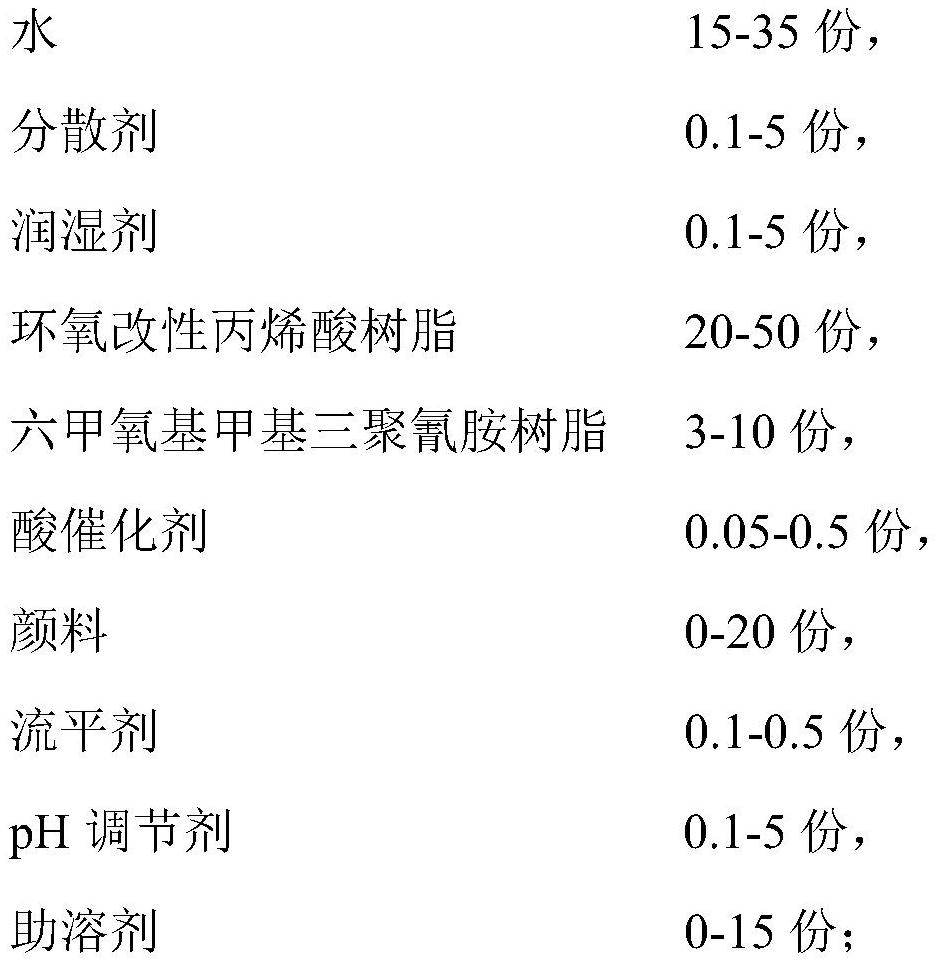

[0049] (1) Prepare the primer: mix the water, dispersant, and wetting agent in the primer components according to the number of parts, then add epoxy modified acrylic resin, hexamethoxymethylmelamine resin and mix evenly, then add Acid catalysts, pigments, leveling agents, pH regulators, and cosolvents are uniformly mixed to obtain the primer;

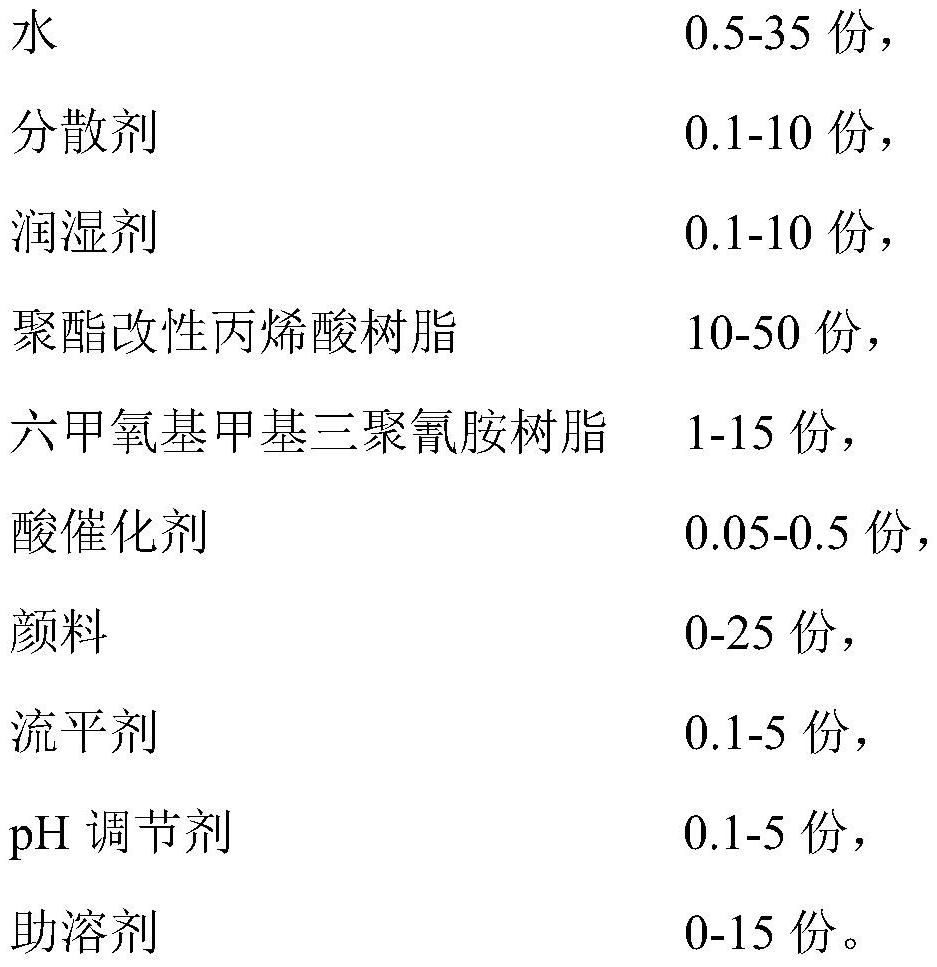

[0050] (2) Preparation of topcoat: Mix the water, dispersant, and wetting agent in the topcoat components according to the number of parts, then add polyester modified acrylic resin, hexamethoxymethylmelamine resin and mix evenly, then add Acid catalysts, pigments, leveling agents, pH regulators, and co-solvents are uniformly mixed to prepare the top coat.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com