High-performance heat conduction material for induction heating equipment

A technology of induction heating equipment and heat-conducting materials, applied in the field of heat-conducting materials, can solve the problems of poor thermal conductivity, poor plasticity, corrosion, etc., and achieve the effects of high plasticity, low vapor pressure, and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

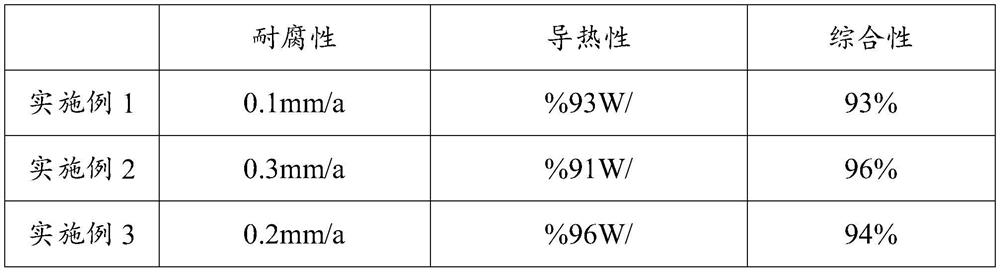

Embodiment 1

[0022] The invention provides a high-performance thermal conductive material for induction heating equipment, which includes the following components: aluminum powder, silicone grease, graphene, polytetrafluoroethylene, niobium powder, tantalum powder, bismuth, sodium alginate, and silicon dioxide;

[0023] Specifically in this embodiment, it is specifically: 30 parts of aluminum powder, 15 parts of silicone grease, 14 parts of graphene, 30 parts of polytetrafluoroethylene, 30 parts of niobium powder, 15 parts of tantalum powder, 15 parts of sodium alginate, two parts 20 parts of silicon oxide;

[0024] Further, in the above-mentioned components, silica is in powder form, and the fineness of the powder particles is specifically 1000 mesh. The aluminum powder, tantalum powder, and niobium powder are all put into a mill and stirred, and the milling time is In 40 minutes, the finally obtained aluminum powder, tantalum powder, and niobium powder are all one-hundredth micron powder part...

Embodiment 2

[0033] The invention provides a high-performance thermal conductive material for induction heating equipment, which includes the following components: aluminum powder, silicone grease, graphene, polytetrafluoroethylene, niobium powder, tantalum powder, bismuth, sodium alginate, and silicon dioxide;

[0034] Specifically in this embodiment, it is specifically: 25 parts of aluminum powder, 13 parts of silicone grease, 15 parts of graphene, 32 parts of polytetrafluoroethylene, 31 parts of niobium powder, 16 parts of tantalum powder, 16 parts of sodium alginate, two parts 22 parts of silicon oxide;

[0035] Further, in the above-mentioned components, silica is in powder form, and the fineness of the powder particles is specifically 1500 mesh. The aluminum powder, tantalum powder, and niobium powder are all put into a mill and stirred, and the milling time is After 50 minutes, the final aluminum powder, tantalum powder, and niobium powder are all one-hundredths of a micron in the form o...

Embodiment 3

[0044] The invention provides a high-performance thermal conductive material for induction heating equipment, which includes the following components: aluminum powder, silicone grease, graphene, polytetrafluoroethylene, niobium powder, tantalum powder, bismuth, sodium alginate, and silicon dioxide;

[0045] In this embodiment, it is specifically: 27 parts of aluminum powder, 16 parts of silicone grease, 16 parts of graphene, 33 parts of polytetrafluoroethylene, 33 parts of niobium powder, 18 parts of tantalum powder, 18 parts of sodium alginate, two parts 24 parts of silicon oxide;

[0046] Further, in the above-mentioned components, silica is in powder form, and the fineness of the powder particles is specifically 1800 mesh. The aluminum powder, tantalum powder, and niobium powder are all put into a mill and stirred, and the milling time is In 60 minutes, the final aluminum powder, tantalum powder, and niobium powder are all one-hundredth micron powder particles, and the powder pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com