Microplastic sampling column, microplastic collection device and in-situ digestion method

A collection device and microplastics technology, applied in the field of microplastics collection device, in-situ digestion, and microplastics sampling column, can solve problems such as fluctuations in the total amount of microplastics, save pre-processing time, reduce errors, ensure reliability and The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The specific parameters for collecting water samples are: seawater in a certain sea area; sampling time: 100min; water collection volume: 1.630m 3 . The sample collected this time is recorded as ES01.

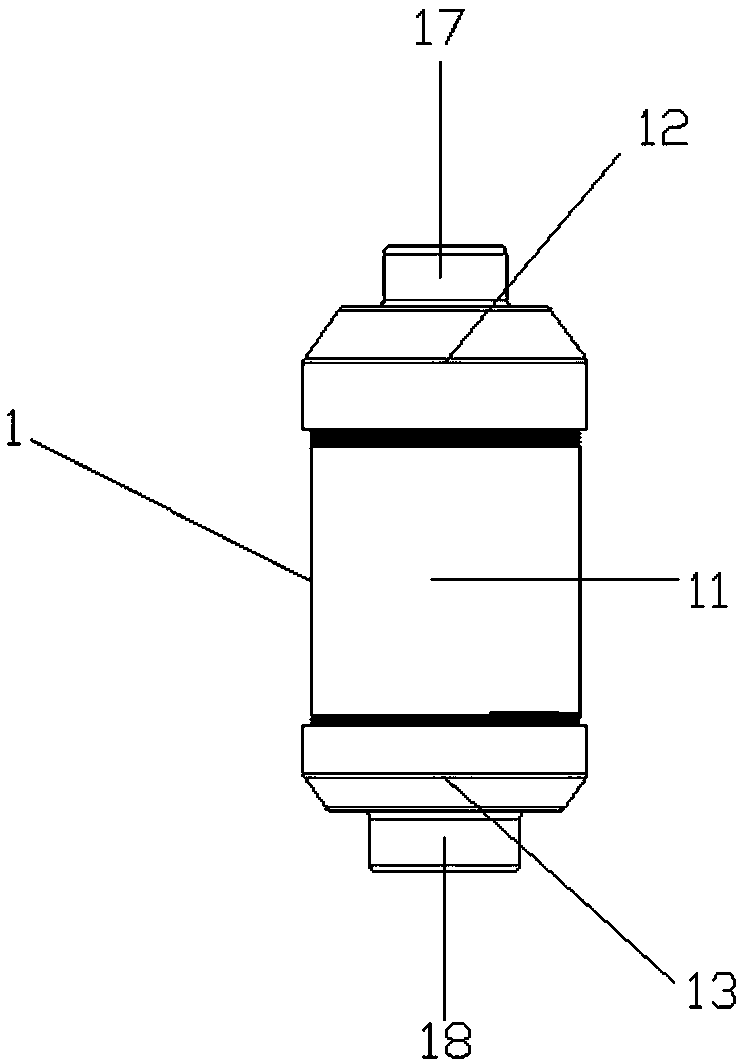

[0042] Separating the microplastics in the collected ES01 samples from other impurities is a crucial step in the analysis and identification of microplastics. Therefore, it is necessary to perform in-situ digestion treatment on the microplastic sampling column 1 enriched with seawater microplastic samples. Seawater contains organic matter such as algae, which need to be removed before identification of microplastics. In the in-situ digestion method based on the microplastic sampling column in the embodiment of the present invention, a stainless steel casing (with a matching stainless steel cover) is used as the digestion device, and the diameter and height of the selected stainless steel casing are slightly larger than the main column 11 in diameter and height.

[00...

Embodiment 2

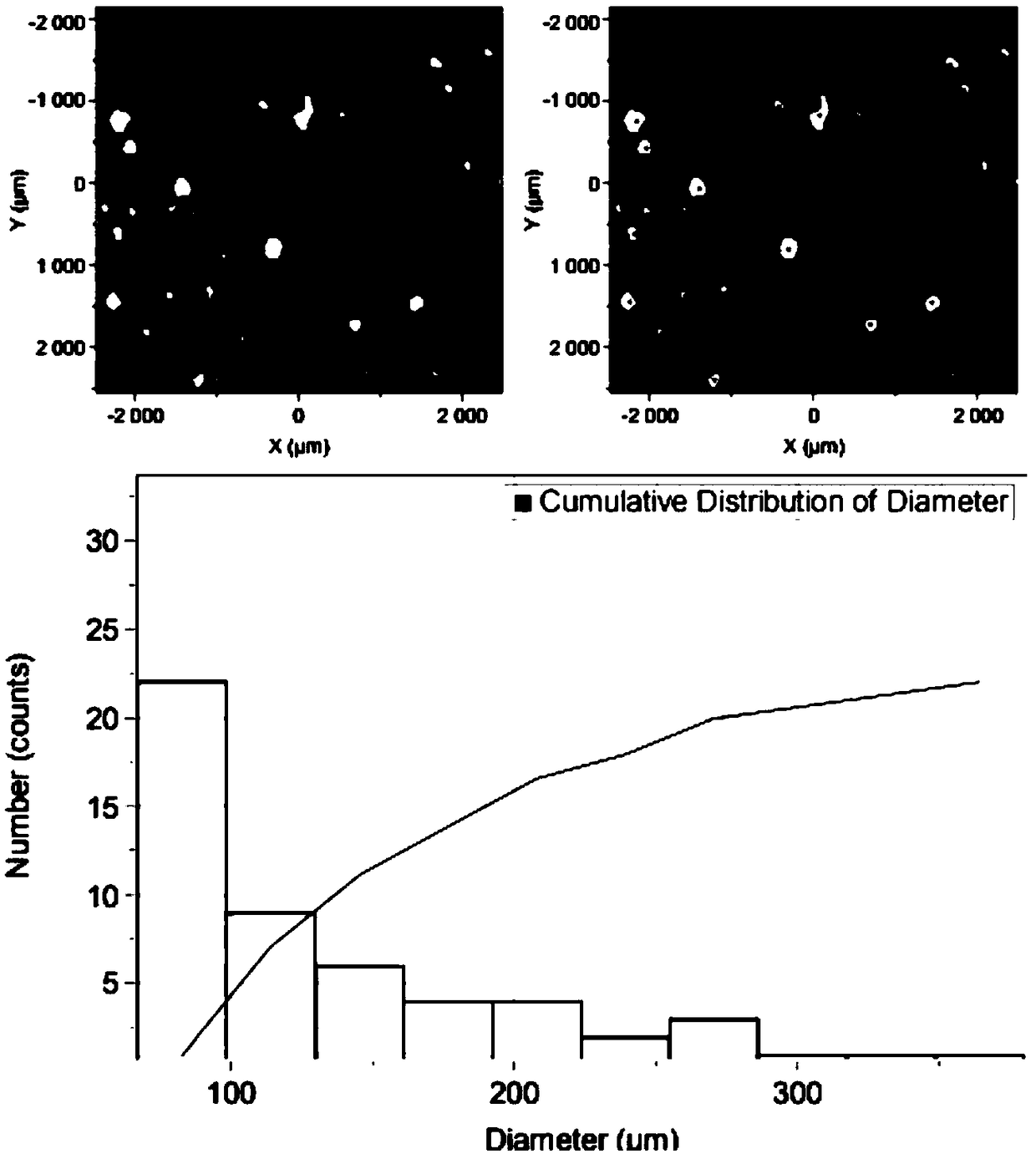

[0056] The specific parameters for collecting water samples are: tap water in a laboratory, the volume of collected water is 50L, and the sample collected this time is recorded as ES02.

[0057] Inject tap water into the experimental pool, add a little polypropylene (PP) particles with a diameter of about 100 μm, use the microplastic collection device to collect the microplastic particles in the experimental pool, and select the aperture of the filter sheet 15 to be 20 μm. Because tap water basically does not contain organic matters such as algae, it does not need digestion treatment, and in this embodiment, the digestion step can be omitted.

[0058] After sampling, the filter sheet 15 in the main column 11 was removed, placed in an oven at 45° C. for drying, and then analyzed and identified directly.

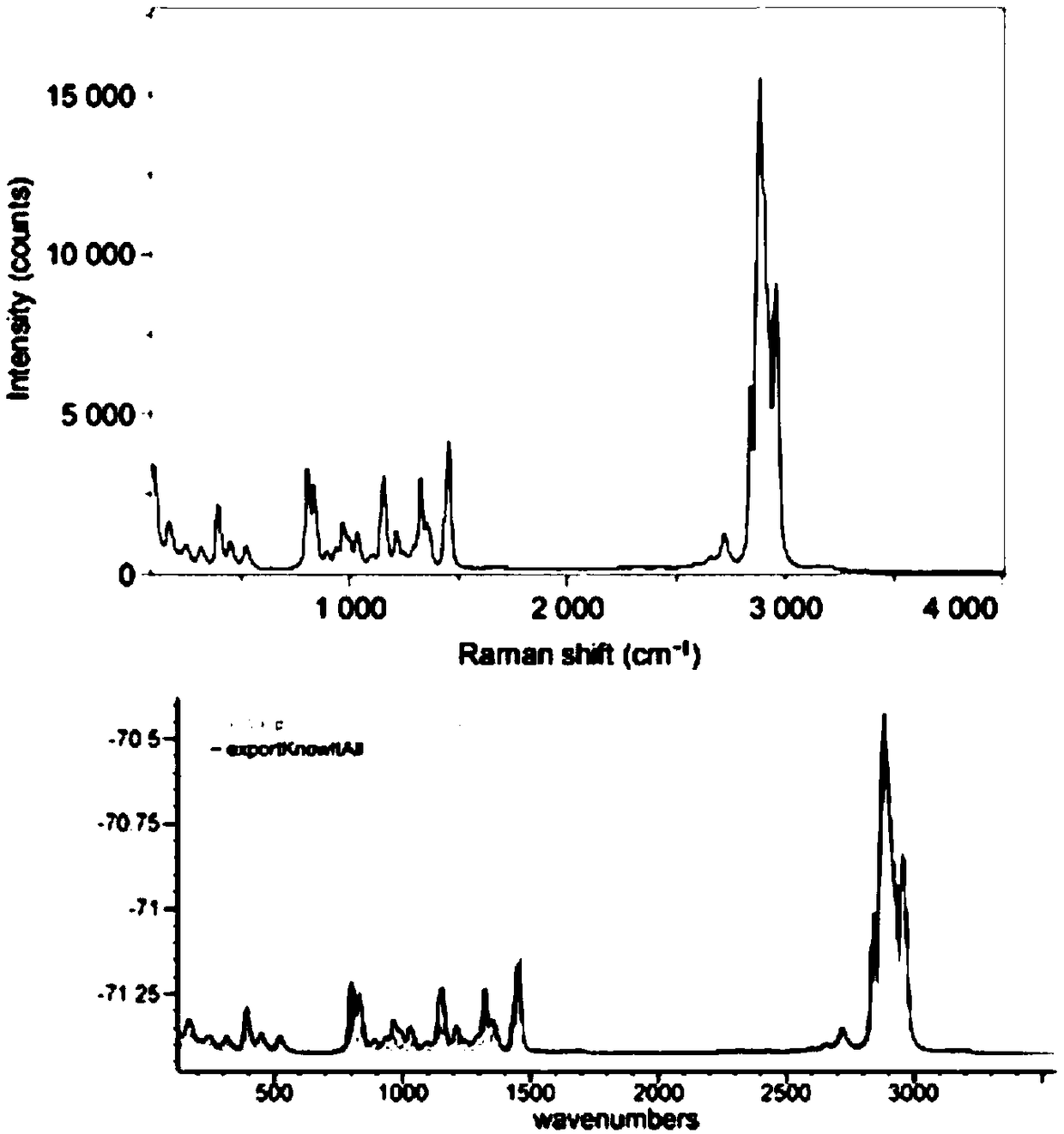

[0059] Raman spectrometer (LabRAM XploRA PLUS) was used for instrument identification, the excitation wavelengths were 532nm and 785nm, and the objective lens: 50×LWD. As a f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com