Method for determining ultrasonic-acoustic emission detection defect depth of composite material

A composite material and defect depth technology, which is applied in the direction of using sound wave/ultrasonic wave/infrasonic wave to analyze solids, analyze materials, and use sound wave/ultrasonic wave/infrasonic wave to analyze materials, etc. It can solve the requirements and limitations that are difficult to meet the requirements and limitations of accurate depth determination of defects Ultrasonic-acoustic emission method detection application, difficulty in determining the depth of detected defects, etc., to achieve good application applicability of engineering detection, conducive to popularization and application, and easy to operate and master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

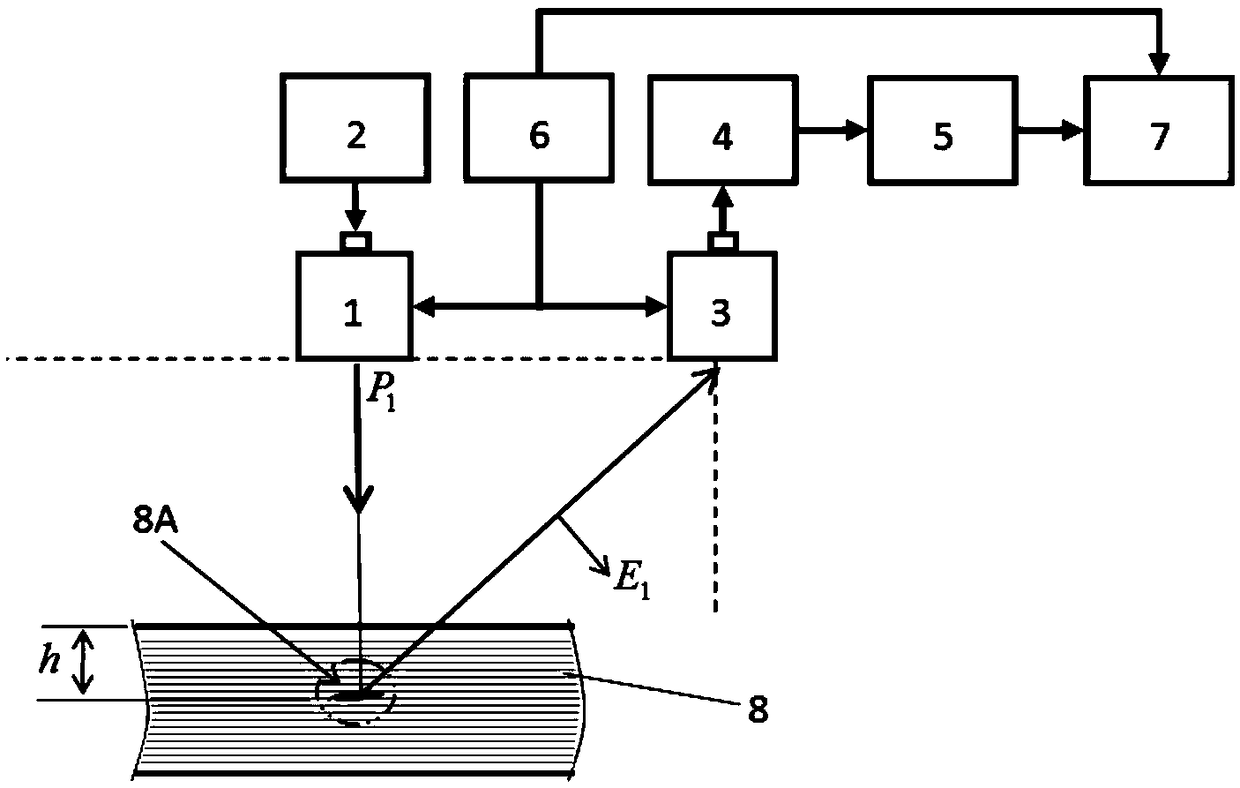

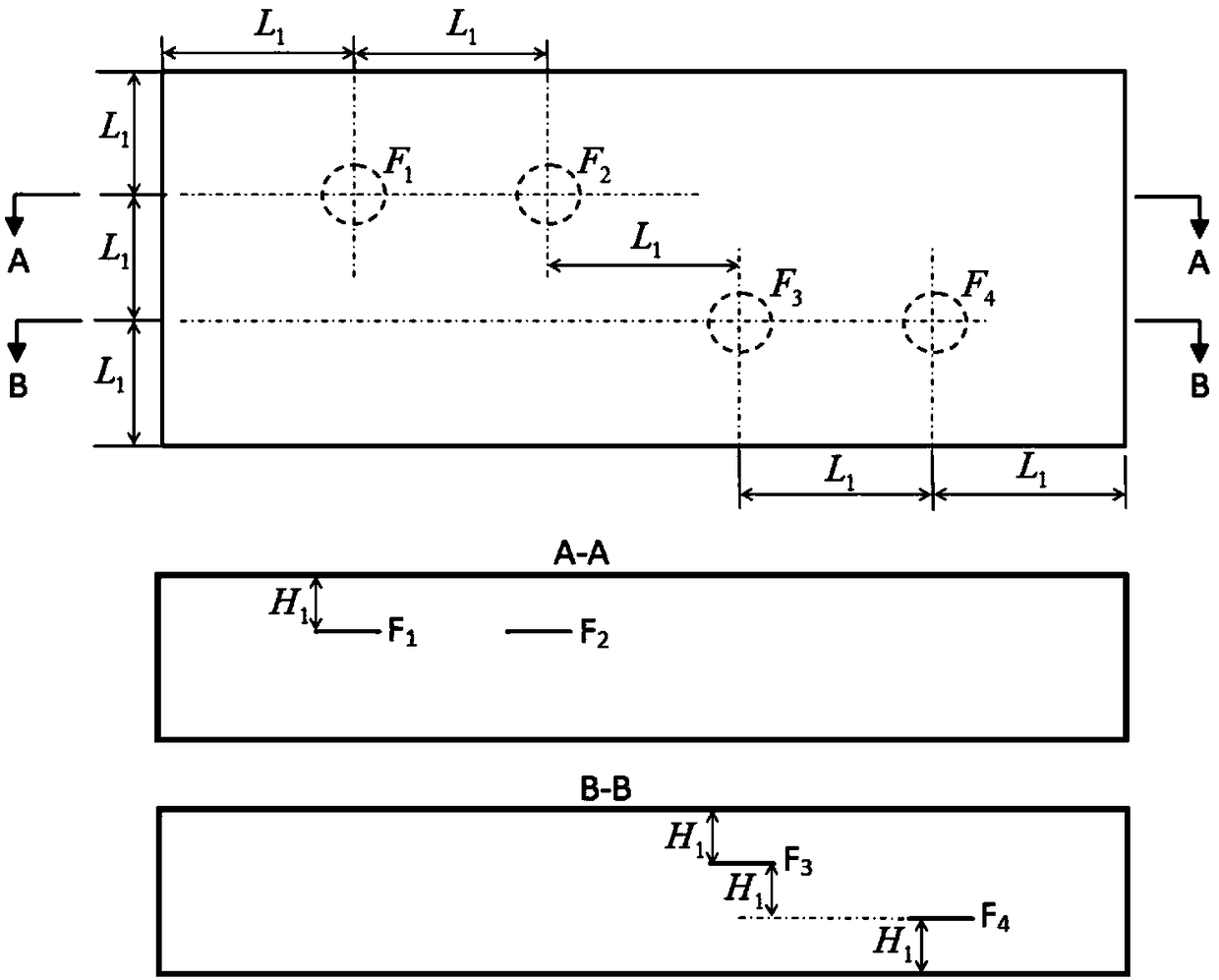

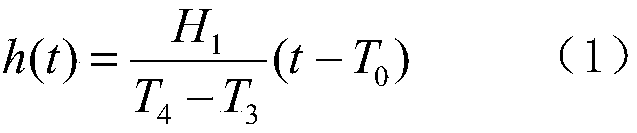

[0050] 1) Preparation of thickness calibration test block

[0051] Using the composite material with the same molding process and material as the composite material to be tested, prepare a thickness calibration test block with a thickness of H. The thickness calibration test block is in the shape of a flat plate with equal thickness. There are 4 prefabricated pieces of the same size at different depths inside the thickness calibration test block. Defect F 1 , F 2 , F 3 , F 4 , its size is selected according to the detection requirements of the composite material structure 8 to be detected, and the defect F 1 , F 2 , F 3 , F 4 The center points of the thickness calibration test block are far away from each other in the plane direction L 1 , defect F 1 , F 2 , F 3 , F 4 The minimum distance between the center point of the thickness calibration test block and the edge near the edge of the thickness calibration test block is not less than L 1 , see figure 2 As shown,...

Embodiment

[0075]Using the method for determining the defect depth of ultrasonic-acoustic emission detection of composite materials in the present invention, select the high-resolution A-U ultrasonic-acoustic emission transducer produced by AVIC Composite Materials Co., Ltd., and use the MUT produced by AVIC Composite Materials Co., Ltd. -1. CUS-21J is used as an ultrasonic-acoustic emission detection instrument unit, and two kinds of thickness reference test blocks are prepared respectively with a carbon fiber composite material laminated structure, and the defect F 1 , F 2 , F 3 , F 4 Choose two different specifications of 3mm and 9mm in diameter respectively,

[0076] H=3mm, corresponding to 24 plies, the nominal thickness of a single ply is about 0.125mm, H 1 = 6 ply thicknesses,

[0077] H=20mm, the corresponding number of layers is 160, the nominal thickness of a single layer is about 0.125mm, H 1 = 40 ply thicknesses,

[0078] According to the defect detection method and ste...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com