Auxiliary heating furnace door system for heat treatment equipment

A heat treatment equipment and auxiliary heating technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as difficulty in meeting high-quality product process requirements, uncontrollable temperature in the furnace mouth area, and poor temperature field stability. The furnace door moves smoothly and reliably, avoiding the lengthening of the heat treatment equipment and reducing the effect of disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

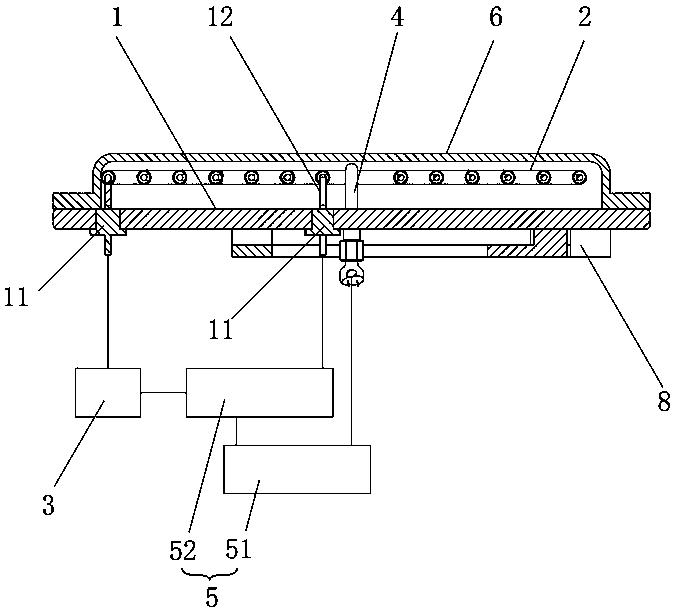

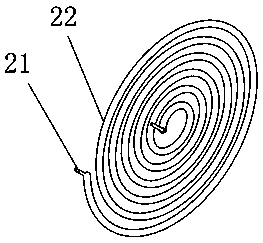

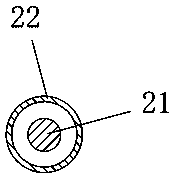

[0025] Figure 1 to Figure 3 An embodiment of the present invention is shown. The heat treatment equipment auxiliary heating furnace door system of this embodiment includes a furnace door 1, and the furnace door 1 is driven by a furnace door driving mechanism 8 to realize stable and reliable opening and closing actions; the furnace door 1 is equipped with an electric heater 2 inside, and the electric heater 2 is equipped with a power module 3, a temperature sensor 4 for detecting the temperature of the furnace mouth area of the heat treatment equipment, and an adjustment component 5 for adjusting the heating power of the electric heater 2, and the power module 3 is connected to the electric heater 2 through the adjustment assembly 5, and the temperature sensor 4 is connected to the adjustment assembly 5.

[0026] The auxiliary heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com