Packaging method and device for manufacturing heat homogenizing plate of vacuum chamber

A packaging method and a technology of packaging devices, which are applied in the direction of indirect heat exchangers, lighting and heating equipment, etc., can solve the problems of unfavorable application and promotion, insufficient internal vacuum degree, low production efficiency, etc., and are conducive to large-scale promotion and reduction Evaporation loss and product cost reduction effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0070] The ultra-thin vapor chamber and its manufacturing method according to the present invention will be further described below in conjunction with specific embodiments.

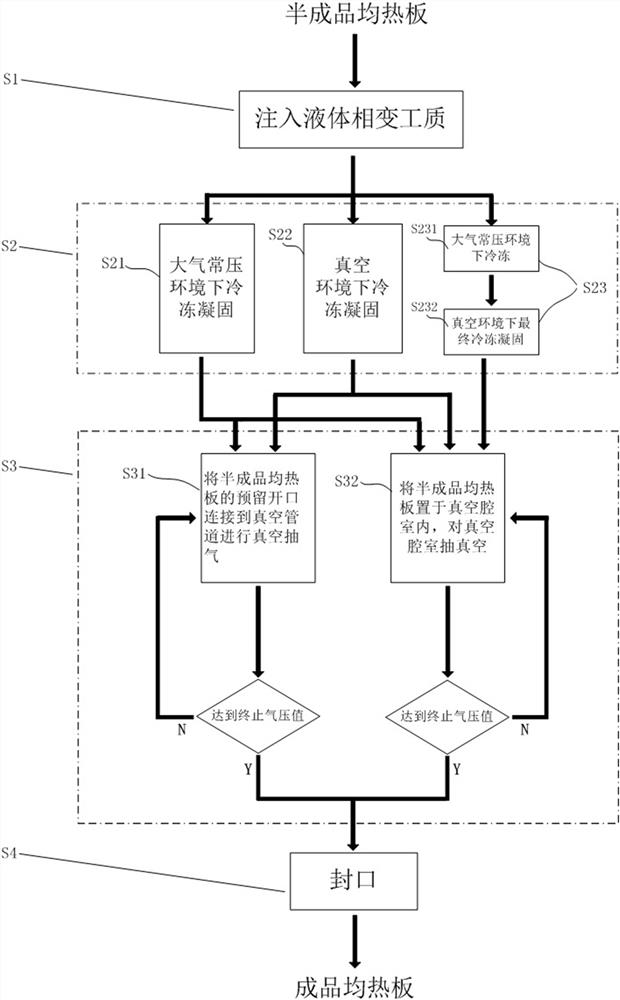

[0071] Such as figure 1 A flow chart of a packaging method for manufacturing a vacuum chamber vapor chamber is shown. The packaged object is a semi-finished vapor chamber with an outer shell, a capillary liquid-absorbing core structure, and a supporting structure. The semi-finished product has an opening reserved before packaging for Injecting working fluid and vacuum pumping; the packaging manufacturing process includes the steps of injecting liquid phase change working fluid (S1), freezing and solidifying (S2), vacuum pumping (S3) and sealing (S4) into the vapor chamber of the semi-finished product.

[0072] First, prepare a semi-finished vapor chamber, on which an opening is reserved for injection of working fluid and vacuum pumping. The methods of reserving the opening can be the following: welding c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com