Automatic mounting device

A kind of equipment and automatic technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of inaccurate placement, huge demand for FPC placement, and low efficiency of manual placement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

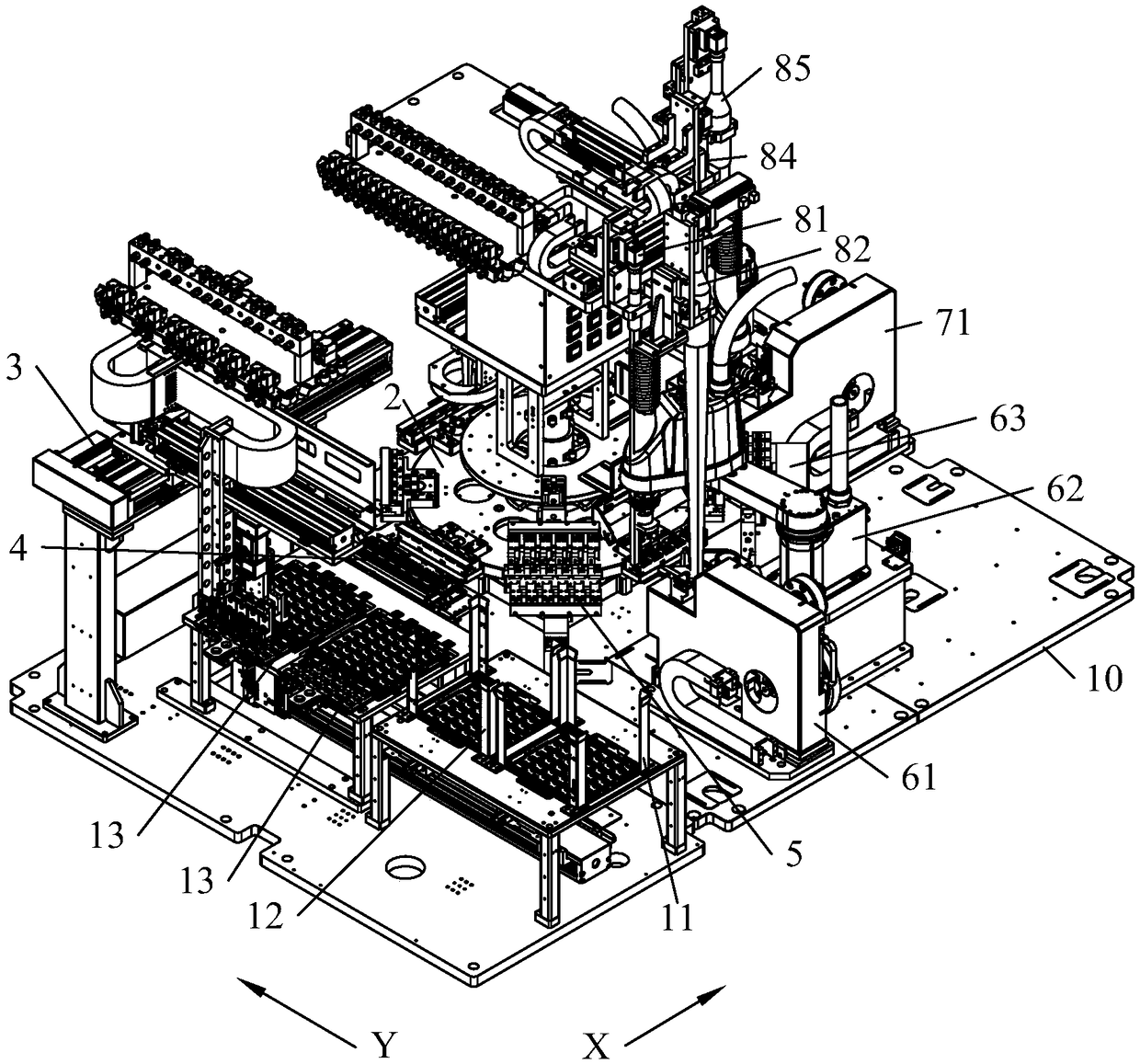

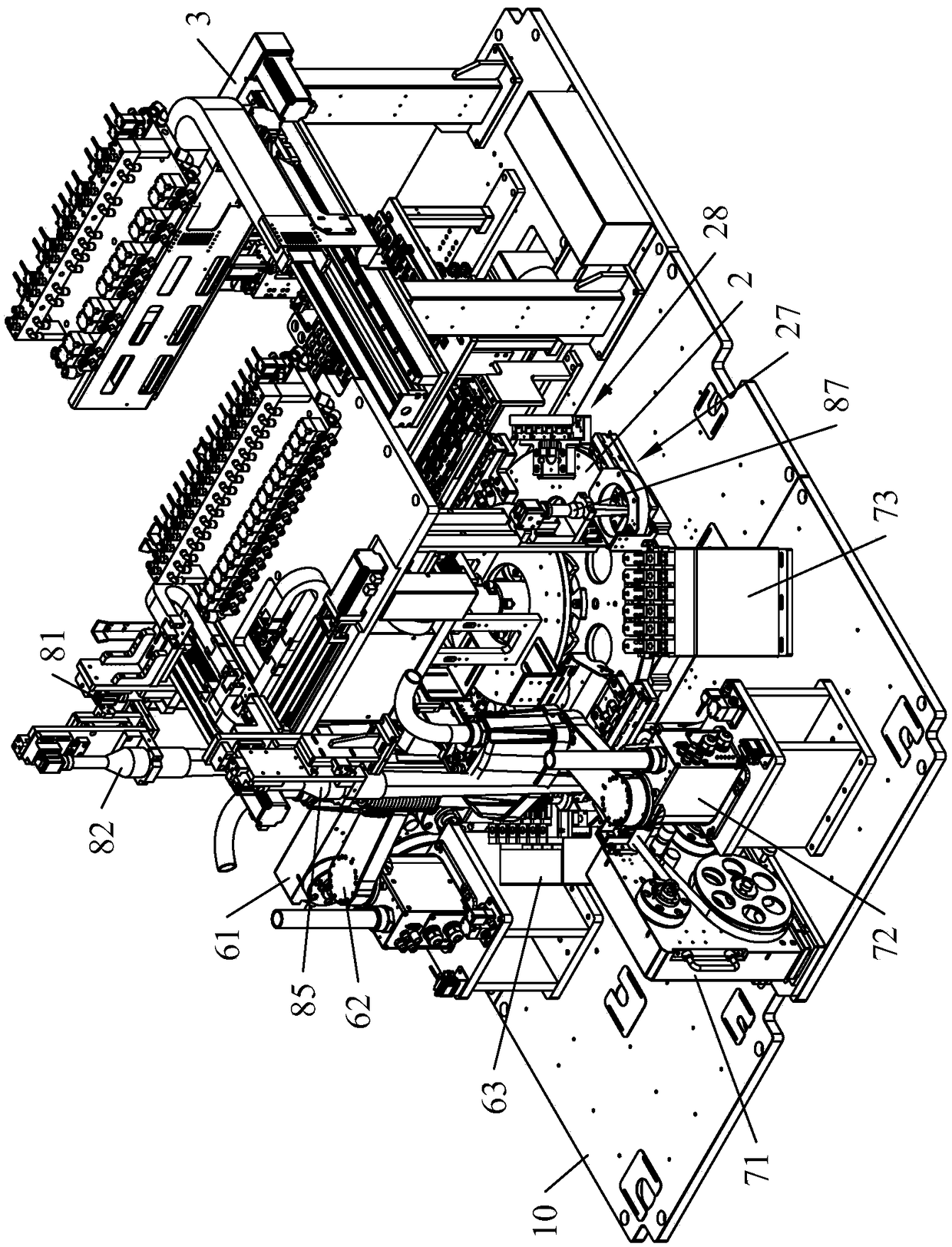

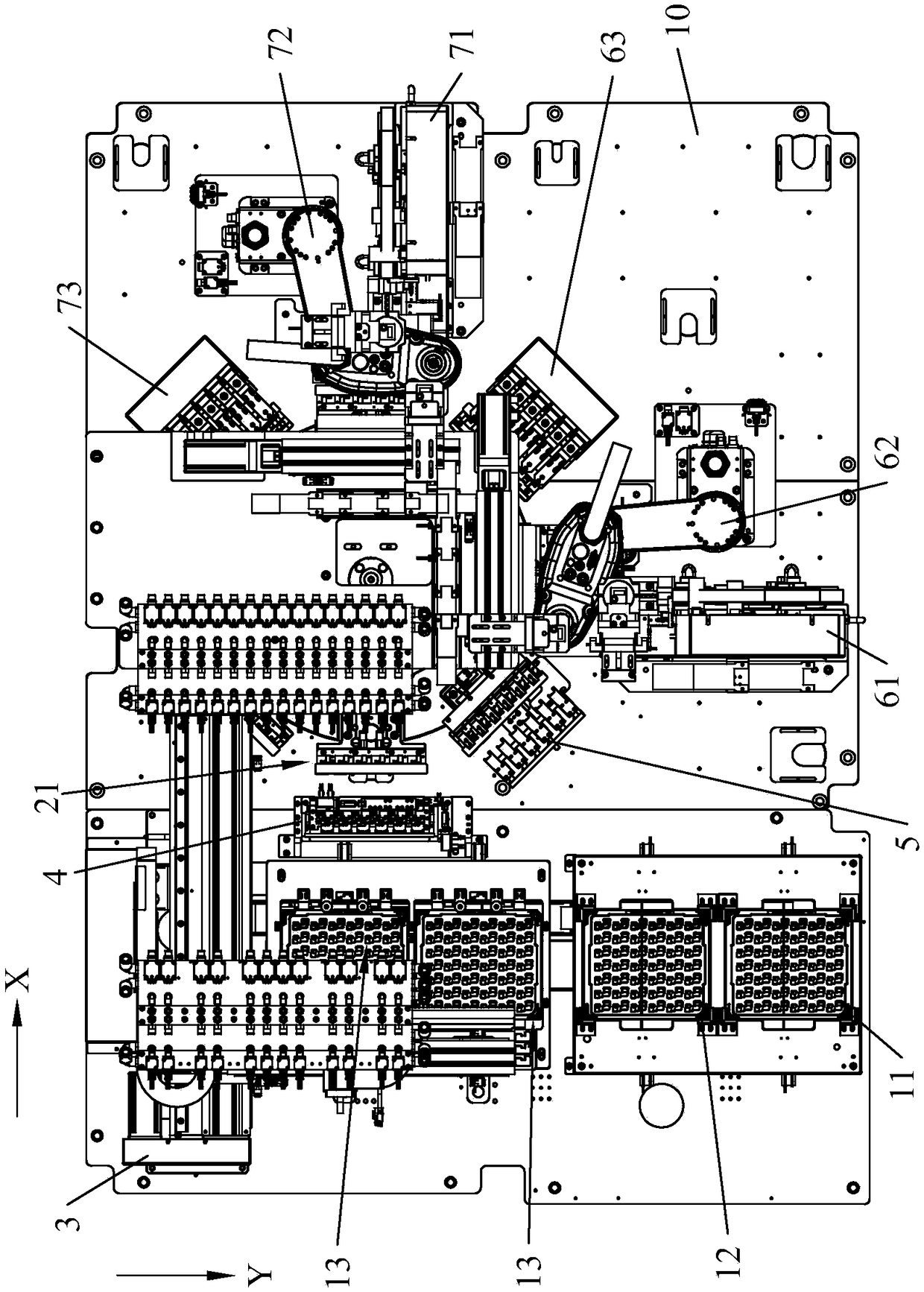

[0034] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0035] combine Figure 1 to Figure 3 As shown, the present invention discloses an automatic placement device for mounting components on FPC. The automatic placement device includes a frame and an upper material bin 11 and a lower material bin 12 arranged on a bottom plate 10 of the frame. , two material stations 13, a turntable 2, a loading and unloading manipulator 3, a pre-positioning device 4, a shaping device 5, a first feeder 61, a first reclaiming manipulator 62 with a first reclaiming suction nozzle, a first holding pressure device 63 , a second feeder 71 , a second reclaiming manipulator 72 with a second reclaiming suction nozzle, and a second pressure maintaining device 73 . In this specification, all other structures of the rack are hidden so that the illustrations can be seen clearly. It can be understood that, in addition to the bottom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com