Trephine having limiting sleeve

A technology of limit sleeve and ring saw, which is applied in the field of medical experiment research, to achieve the effects of easy mastering, saving time and money, and low power consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

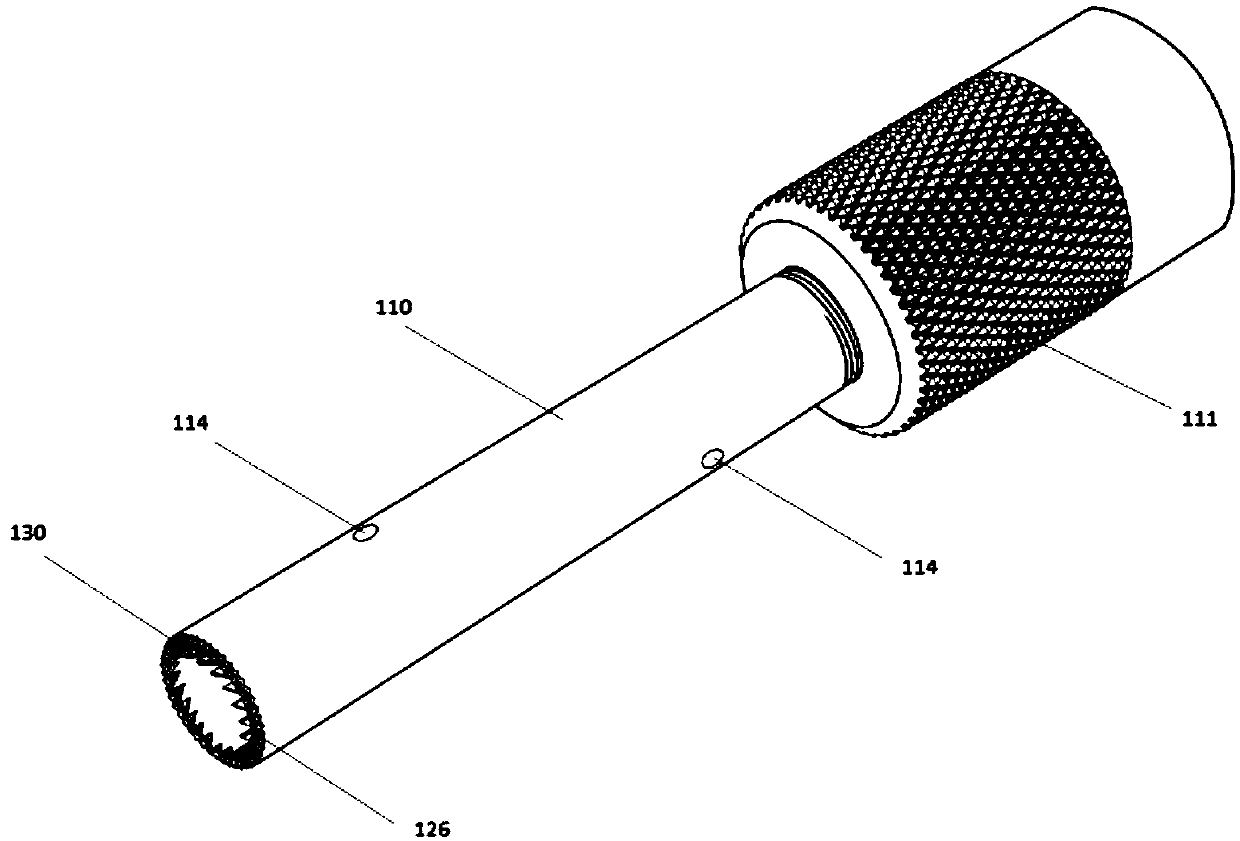

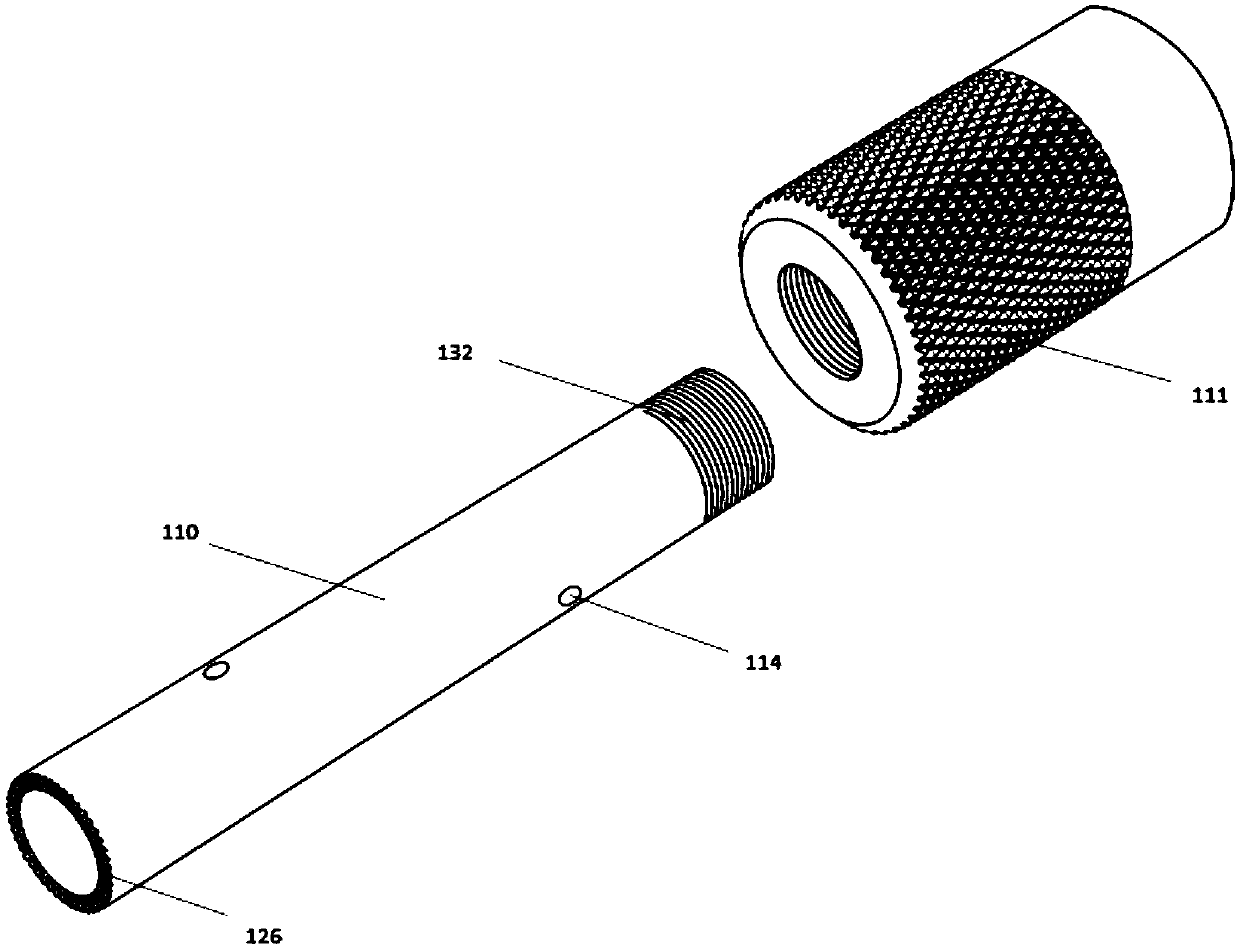

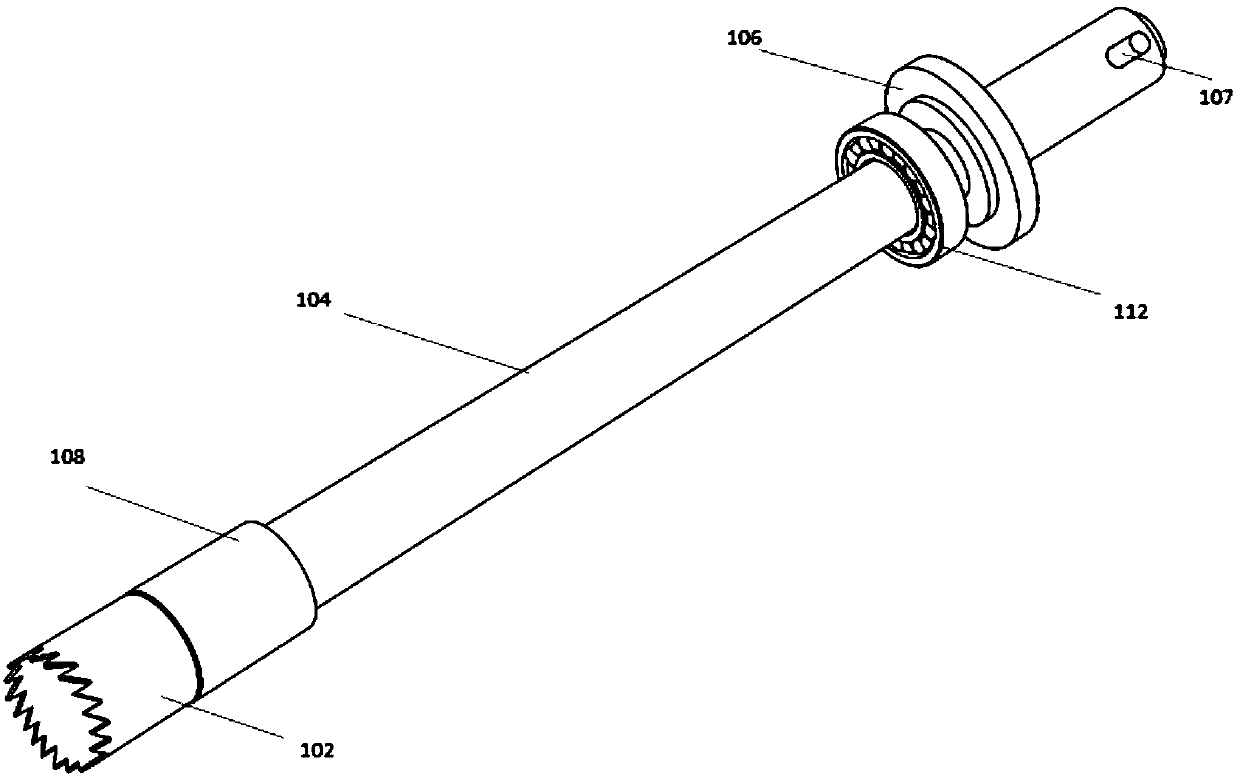

[0065] Such as Figure 1-15 The limit sleeve ring saw shown includes an inner ring saw and a ring saw sleeve 110; the inner ring saw is sleeved in the ring saw sleeve 110 and driven to rotate by a motor; the inner ring saw includes a ring saw drill bit 102, The connecting rod shaft 104, the coupling A106 and the coupling fork pin 107; the ring saw drill bit 102 is arranged on one end of the connecting rod shaft 104, and the front end of the ring saw drill bit 102 is provided with a trephine saw tooth 130, and the trephine saw tooth 130 can extend out of the ring saw The front end of the sleeve 110 is at a certain distance, and the other end of the connecting rod shaft 104 is connected to the motor shaft 206 through a coupling A106 and a coupling fork pin 107 . The external trephine sleeve 110 protects the built-in internal trephine from injuring the operator and the surrounding tissues of the surgical site; it is possible to hold the front end of the trephine sleeve tightly wi...

Embodiment 2

[0072] Such as Figures 16-21 As shown, the motor 200 includes a motor housing 208, a motor shaft 206, and a coupling B202; the coupling B202 is provided with a coupling B groove 204 with a fan-shaped opening, and the coupling A106 is connected to the coupling B202. The coupling fork pin 107 is stuck in the groove 204 of the coupling B. The limit sleeve ring saw is embedded and connected with the coupling A106 and the coupling B groove 204 of the shaft coupling B, so that the sleeve ring saw is easy to load and unload. During the actual loading and unloading operation, the coupling A106 can easily slide into the coupling B202 on the motor shaft 206, and the coupling fork shaft 107 on the coupling A can slide freely into the fan-shaped opening coupling B of the coupling B202 Groove 204, this kind of fan-shaped modular embedded coupling connection is very easy for users to install and disassemble, and their embedded coupling does not need to pay attention to alignment adjustmen...

Embodiment 3

[0074] Such as Figure 22-24 In the limiting sleeve ring saw shown, the ring saw sleeve includes a front end sleeve 302 and a main section ring saw sleeve 306 ; The detachable front sleeve 302 part and the built-in trephine drill bit 102, as the effective working part of performing the operation, can be conveniently taken off together for high-temperature sterilization. In addition, for the convenience of clinical operations and the requirement of different drilling depths of the skull plate, the front sleeve 302 can be made of plastic material to make a complete set of spare parts with different sequence lengths for one-time use during clinical operations.

[0075] Please refer to the description of Example 1 for other contents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com