Laser engraving and printing process as well as equipment for implementing laser engraving and printing process

A technology of laser engraving and printing technology, applied in laser welding equipment, metal processing equipment, welding equipment, etc., can solve the problems of lack of individuality, pattern wear, monotonous color and pattern, etc., and achieve non-fading, continuous production, color pattern Variety of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention is further described in conjunction with the following examples.

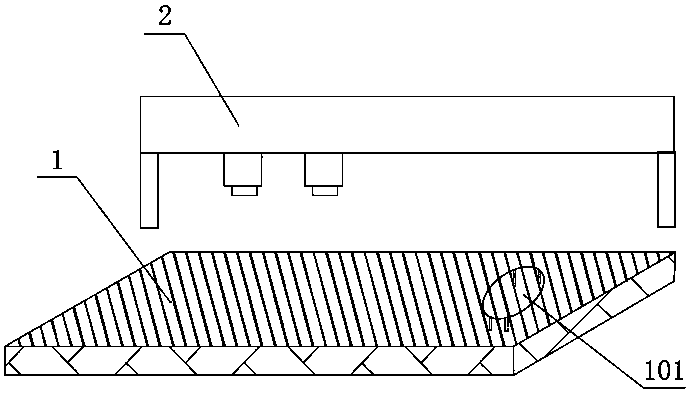

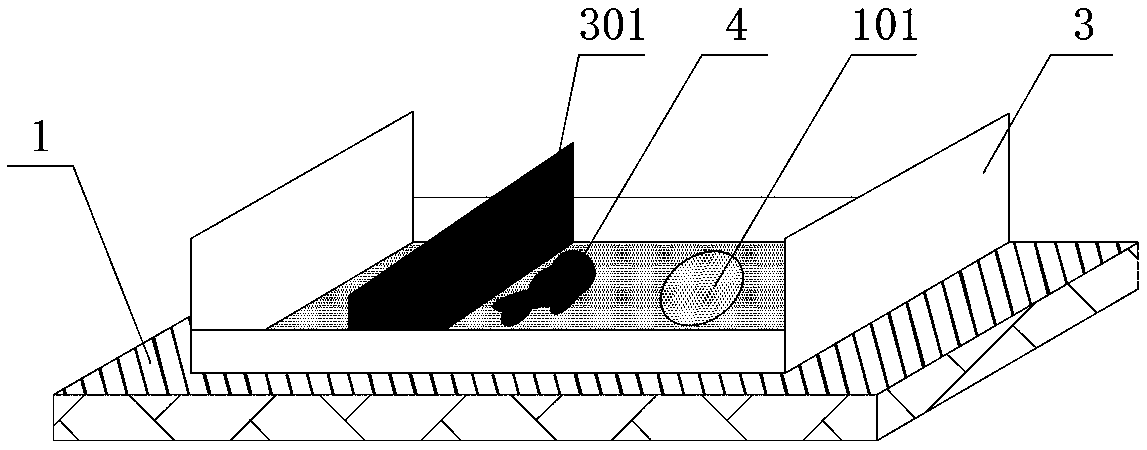

[0056] A kind of laser engraving printing process of the present embodiment, refer to Figure 1 to Figure 3 , including the following steps:

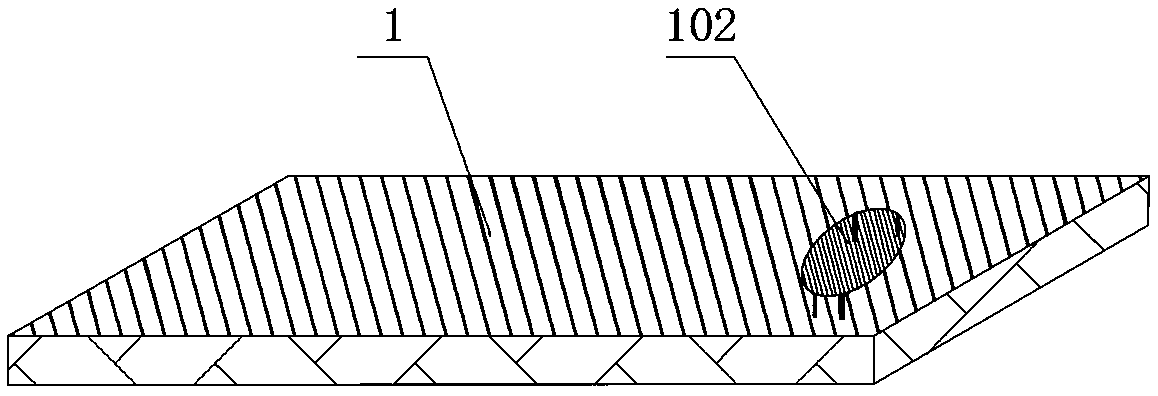

[0057] S1. Select base material 1: The base material is one of felt, veneer products and PU products. The width of the base material is less than 80cm. Among them, the felt is a product formed by chemical bonding or hot-melt method, which can be made according to customer needs. Base color dyeing processing;

[0058]S2. Analyzing the pore structure of the base material with a microscope or an electron microscope and designing a printing sample;

[0059] S3. Color-separated printing screens. Make an independent printing screen for each color, the pattern precision is ≤3000dpi, the mesh of the flower screen is ≤300 mesh, and the number of flower screens is not more than 8. When printing, the colors are printed one by one from light to dark, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com