Crystal growth furnace of fiber polarizer

A crystal growth furnace and crystal growth technology, applied in the direction of crystal growth, single crystal growth, single crystal growth, etc., can solve the problems of affecting product quality, many crystal growth defects, and difficulty in controlling the temperature field distribution of the furnace cavity, etc., and achieve reduction Effect of growth defect rate and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described below in conjunction with the drawings and embodiments:

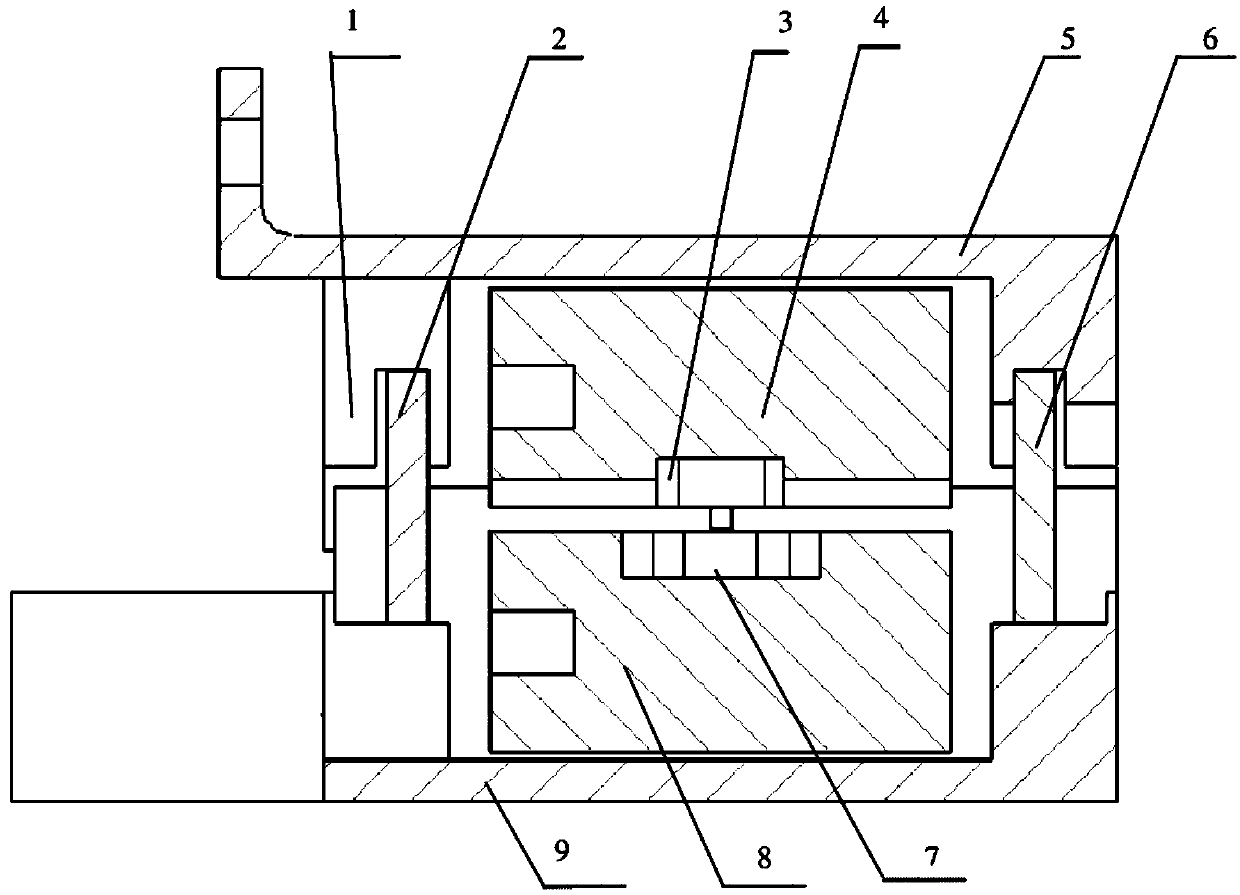

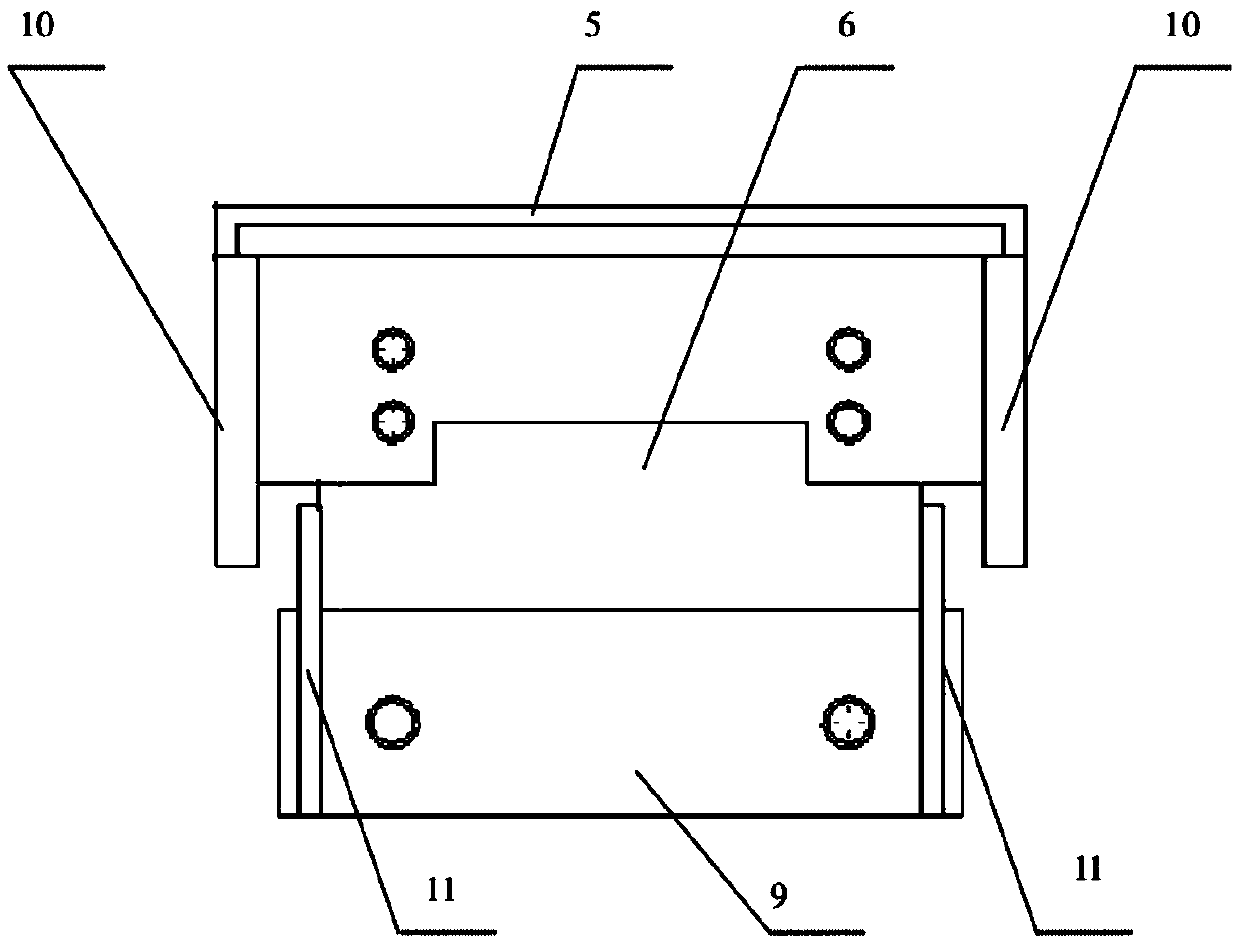

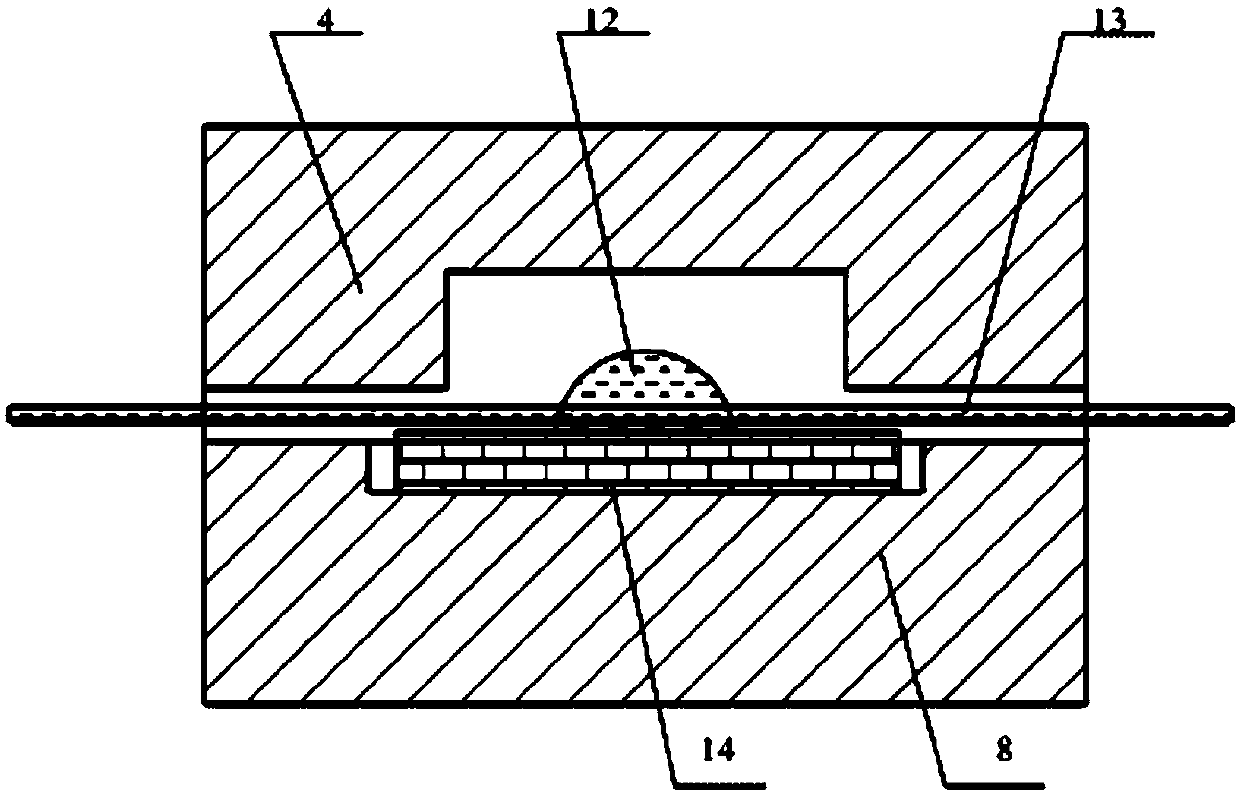

[0019] See also figure 1 with figure 2 , The fiber polarizer crystal growth furnace of the present invention is composed of an upper heating furnace 4 and a lower heating furnace 8 arranged in correspondence with each other up and down, wherein the upper heating furnace 4 is provided with a crystal growth cavity 3, and the lower heating furnace 8 corresponds to the crystal growth cavity A substrate slot 7 is provided at the 3 position. The cross section of the crystal growth cavity 3 is basically the same as the shape of the crystal 12, but the cross section area of the crystal growth cavity 3 is much larger than the cross section size of the crystal 12, and the two maintain a symmetrical distance. In addition, the upper heating furnace 4 and the lower heating furnace 8 select suitable materials as the furnace body material to ensure the minimum thickness in the proc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com