Fruit tree branch automatic trimming system and trimming method for agricultural greenhouse

A technology for automatic pruning and fruit trees, which is applied in agriculture, transmission systems, pruning and shearing equipment, etc. It can solve the problems of increasing the risk of rheumatism, reducing the efficiency of pruning, and damaging the health of the body, so as to improve the efficiency of branch pruning, Effect of improving working environment and reducing labor cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] An automatic pruning system for fruit tree branches for agricultural greenhouses, including a transmission module, an image acquisition module, a control module, a pruning module, a rotation module, a controller and a server;

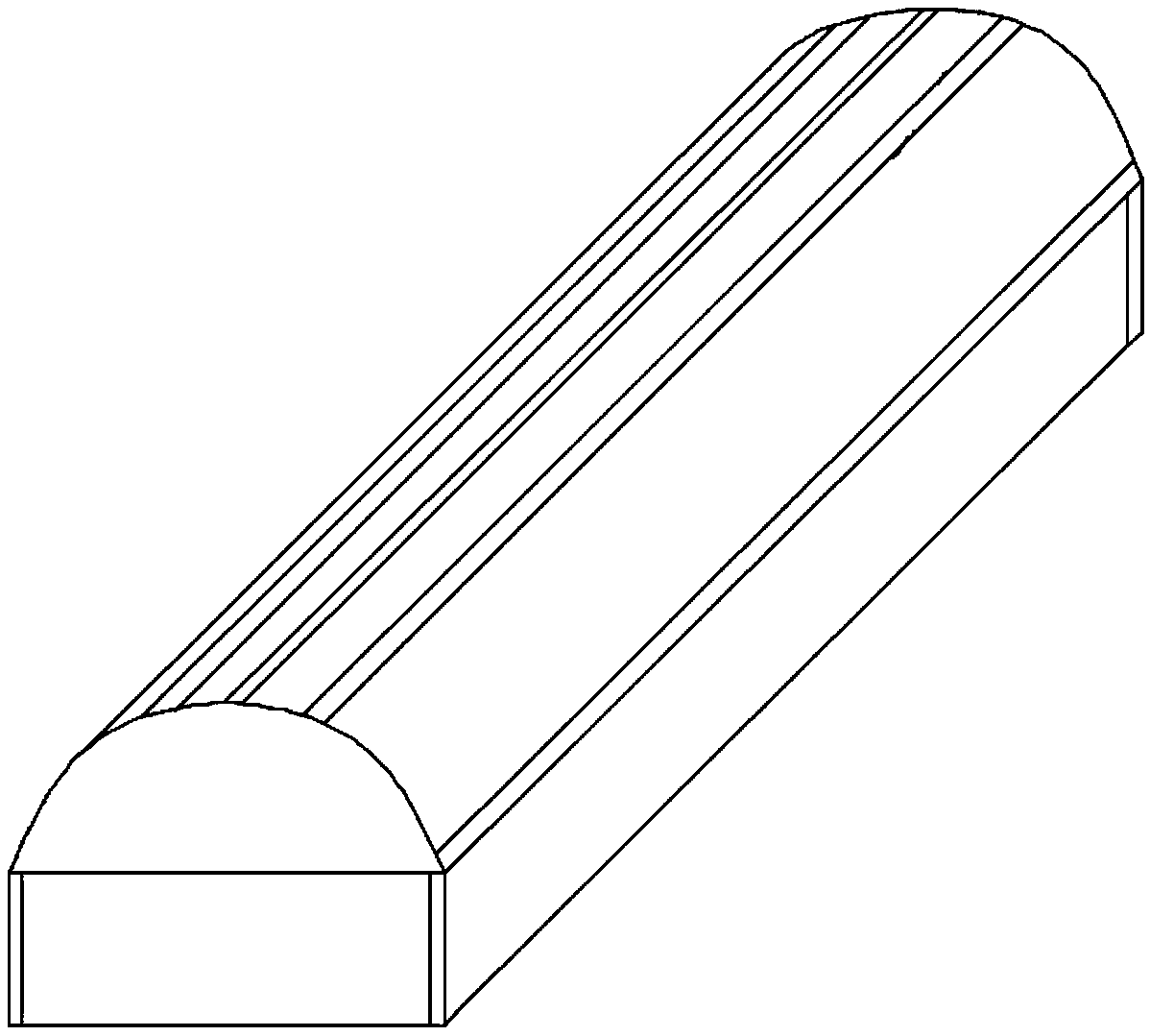

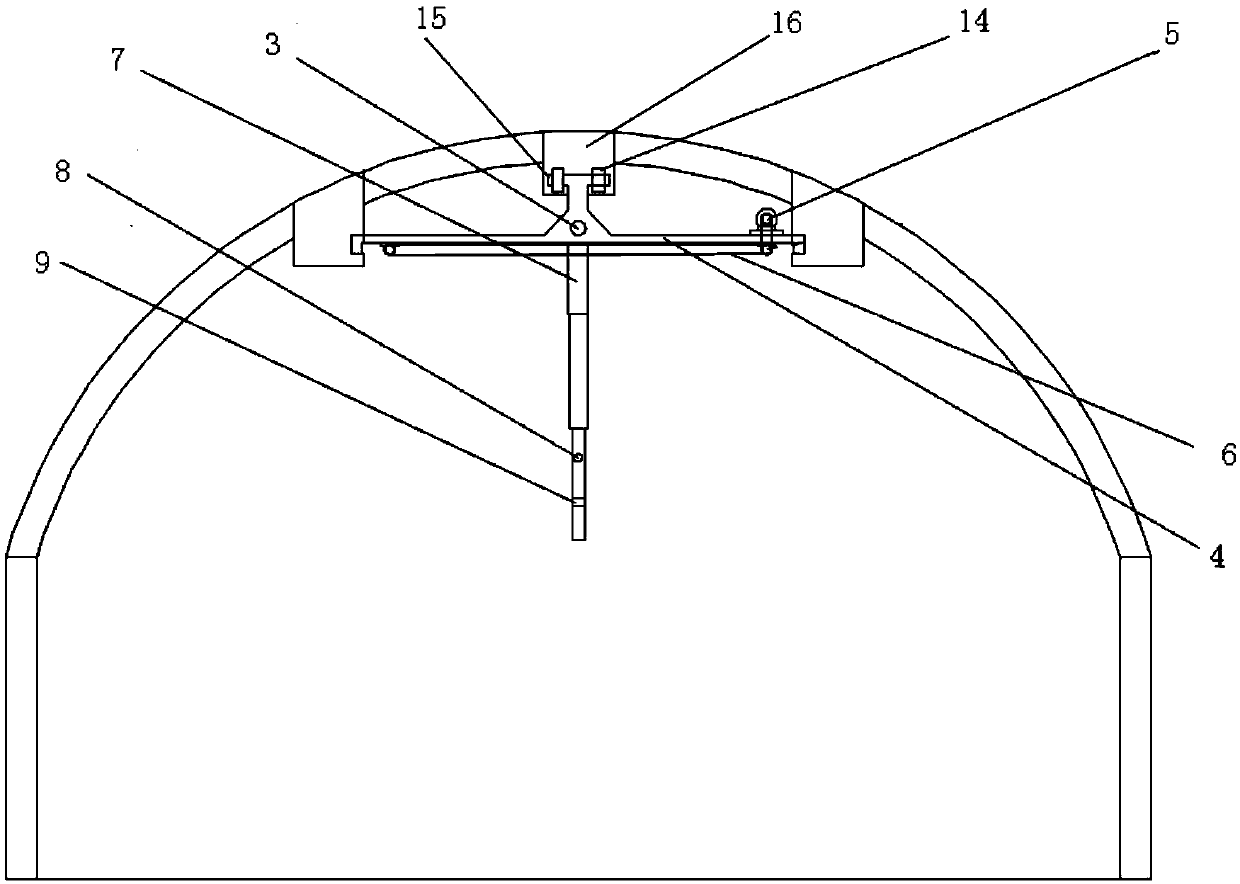

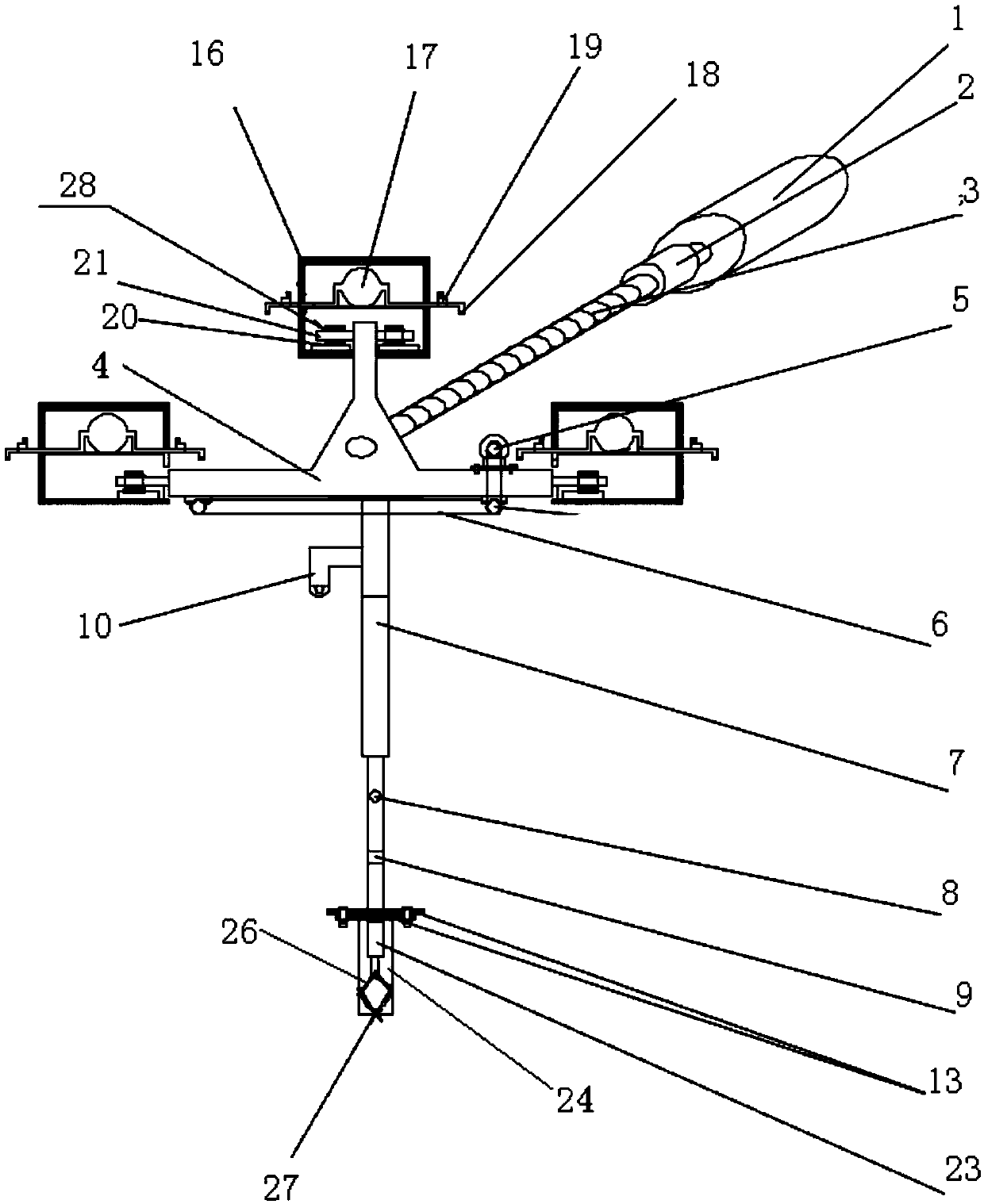

[0041] The transmission module includes an X-direction transmission module, a Y-direction transmission module and a Z-direction transmission module; wherein, the Y-direction transmission module is fixed on the longitudinal beam of the greenhouse, and the longitudinal beam is a hollow groove with an open slideway formed on the lower surface; as figure 1 As shown, the Y-direction transmission module includes a longitudinal servo motor 1, a coupling 2, a trapezoidal screw 3 and an inverted T-shaped bracket 4, and the center of the inverted T-shaped bracket 4 is provided with a threaded hole matching the trapezoidal screw 3; The lead screw 3 has higher transmission efficiency than the ordinary lead screw, has a high tooth shape strength, can withstand...

Embodiment 2

[0047] The difference with Embodiment 1 is that the automatic pruning system for fruit tree branches in this agricultural greenhouse also includes several spraying modules arranged on the longitudinal beams of the greenhouse, such as Figure 4 As shown, the sprinkler module includes a number of water supply 17 arranged inside the longitudinal beam of the greenhouse; several spray pipes are arranged at equal intervals on both sides of the water supply pipeline 17, and one end of the spray pipe is connected to the water supply pipeline 17, the other end is connected with a nozzle 18, and a solenoid valve 19 is arranged inside each nozzle, and the solenoid valve 19 is connected to the controller;

[0048] The spraying module can be used to spray pesticides for fruit trees, and can also be used to add water to the surface of leaves or spray foliage fertilizer. The controller controls the opening and closing of the solenoid valve 19 to control the conduction and shutdown of the spra...

Embodiment 3

[0050] The difference from Example 1 is that the automatic pruning system for fruit tree branches in this agricultural greenhouse also includes a pollination module, such as Figure 7 As shown, the pollination module includes a fixed plate 29, an electric push rod 30, an air storage tank 31, a pollen tank 32, and a pollination rod 33; the electric push rod 30 and the pollen tank 32 are all fixed on the fixed plate 29, and the electric push rod 30 The air outlet of the air storage tank 31 is connected to the air inlet of the air storage tank 31, and the air outlet of the air storage tank 31 is connected to the pollination bar 33 through a pipeline. The material of the pollination bar 33 is a breathable macroporous sponge, which can effectively Prevent pollen waste and improve the utilization rate of pollen; the pollen tank 32 and the air storage tank 31 are set at the same height, which is conducive to the pollen in the pollen tank 32 sliding into the air outlet of the air stora...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com