Preparation method of fresh pseudo-ginseng freeze-dried wall-breaking submicron powder

A technology of superfine powder and notoginseng, which is applied in the field of preparation of fresh notoginseng freeze-dried and broken wall superfine powder, which can solve the problems of unstable fineness, easy agglomeration, high loss, etc., reduce grinding energy consumption, reduce grinding requirements, and improve release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

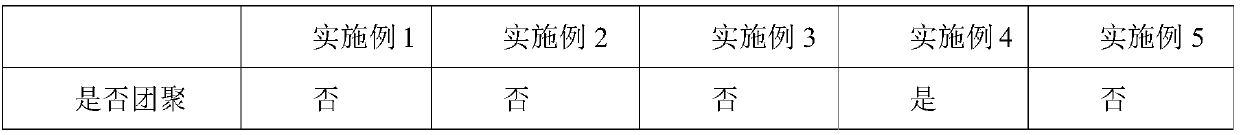

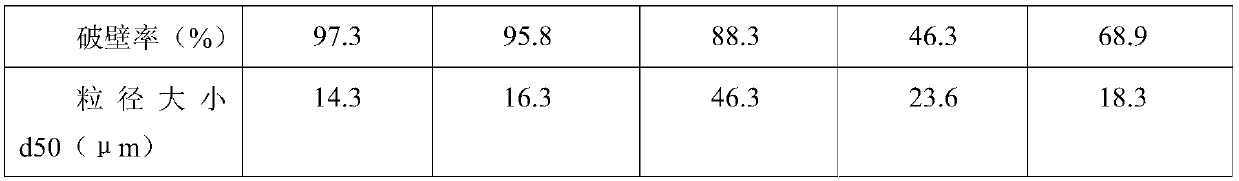

Embodiment 1

[0023] A preparation method of fresh notoginseng freeze-dried broken wall superfine powder,

[0024] (1) Soak fresh Panax notoginseng in water, and perform wet crushing after soaking;

[0025] (2) vacuum freeze-drying the notoginseng wet powder after wet crushing;

[0026] (3) The notoginseng powder after vacuum freeze-drying is subjected to wall-breaking treatment.

[0027] The crushing speed is 900r / min, and the crushing time is 20min; in the vacuum freeze-drying step, the thickness of the material is 0.5mm, the freeze-drying temperature is -10°C, and the freeze-drying vacuum is 5Pa; after freeze-drying, the temperature is raised rapidly; In the treatment step, the wall-breaking temperature is 15°C, and the wall-breaking time is 20 minutes; an ultrasonic treatment step is also included before the wall-breaking treatment step; the ultrasonic treatment time is 40 minutes;

Embodiment 2

[0029] A preparation method of fresh notoginseng freeze-dried broken wall superfine powder,

[0030] (1) Soak fresh Panax notoginseng in water, and perform wet crushing after soaking;

[0031] (2) vacuum freeze-drying the notoginseng wet powder after wet crushing;

[0032] (3) The notoginseng powder after vacuum freeze-drying is subjected to wall-breaking treatment.

[0033] The crushing speed is 700r / min, and the crushing time is 15min; in the vacuum freeze-drying step, the material thickness is 0.8mm, the freeze-drying temperature is -15°C, and the freeze-drying vacuum degree is 10Pa; in the wall-breaking treatment step, the wall-breaking temperature is 10°C, the wall-breaking time is 40 minutes; before the wall-breaking treatment step, an ultrasonic treatment step is also included; the ultrasonic treatment time is 70 minutes;

Embodiment 3

[0035] The process steps and parameters of the preparation method of Example 1 are basically the same, the difference is that the fresh Panax notoginseng is not soaked in water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com