Methods for applying polyurethane coatings to golf balls having a thermoplastic polyurethane cover

A thermoplastic polyurethane, polyurethane coating technology, applied in polyurea/polyurethane coatings, coatings, chemical instruments and methods, etc., can solve problems such as reducing processing efficiency and time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

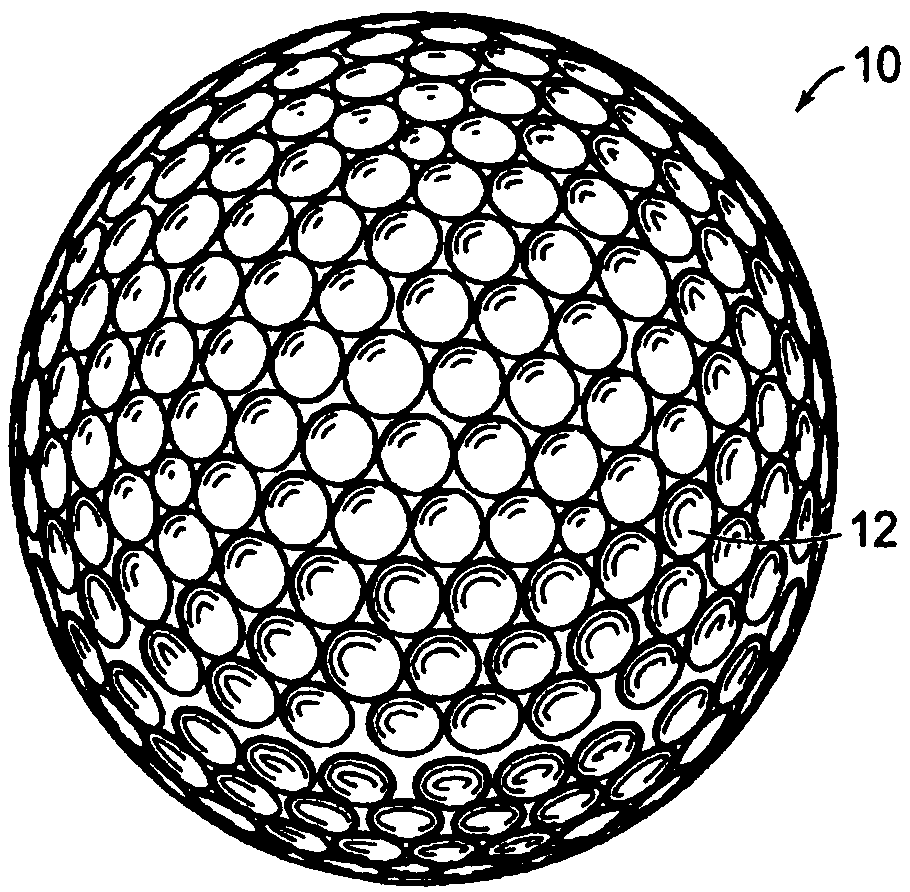

[0024] This invention generally relates to golf balls having covers made from thermoplastic polyurethane (TPU) compositions. Various polyurethane primers and topcoats were applied to the polyurethane outer coating according to the invention. The invention also includes the final golf balls produced from the application of these coatings.

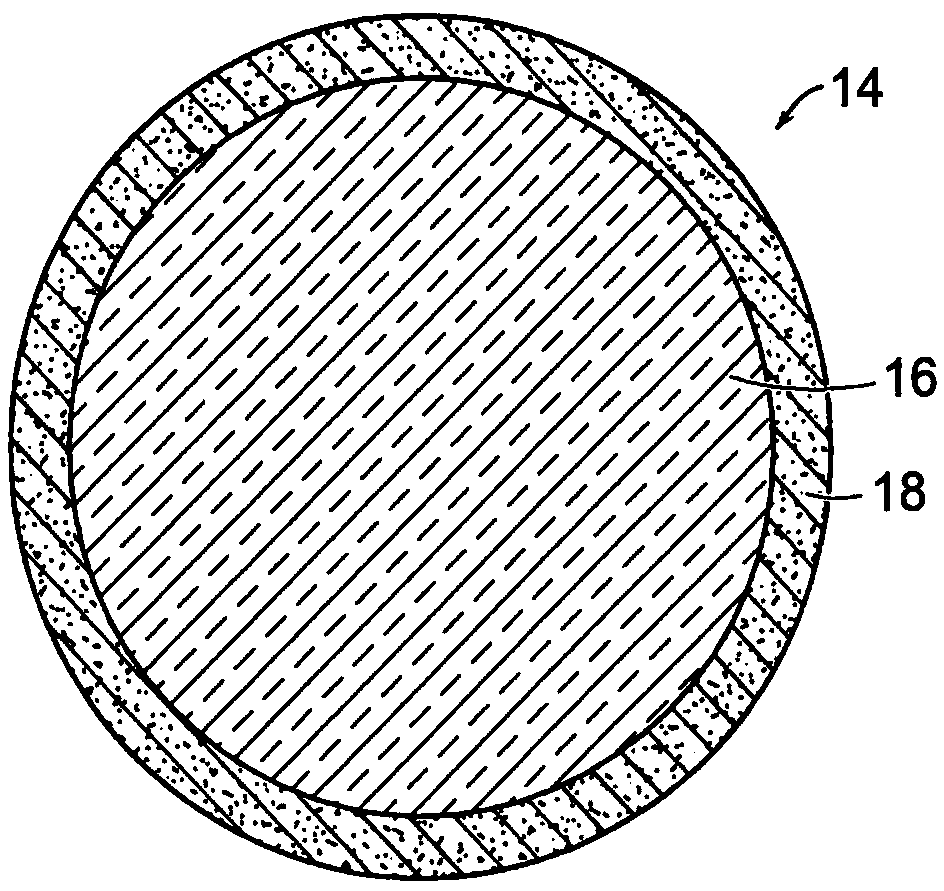

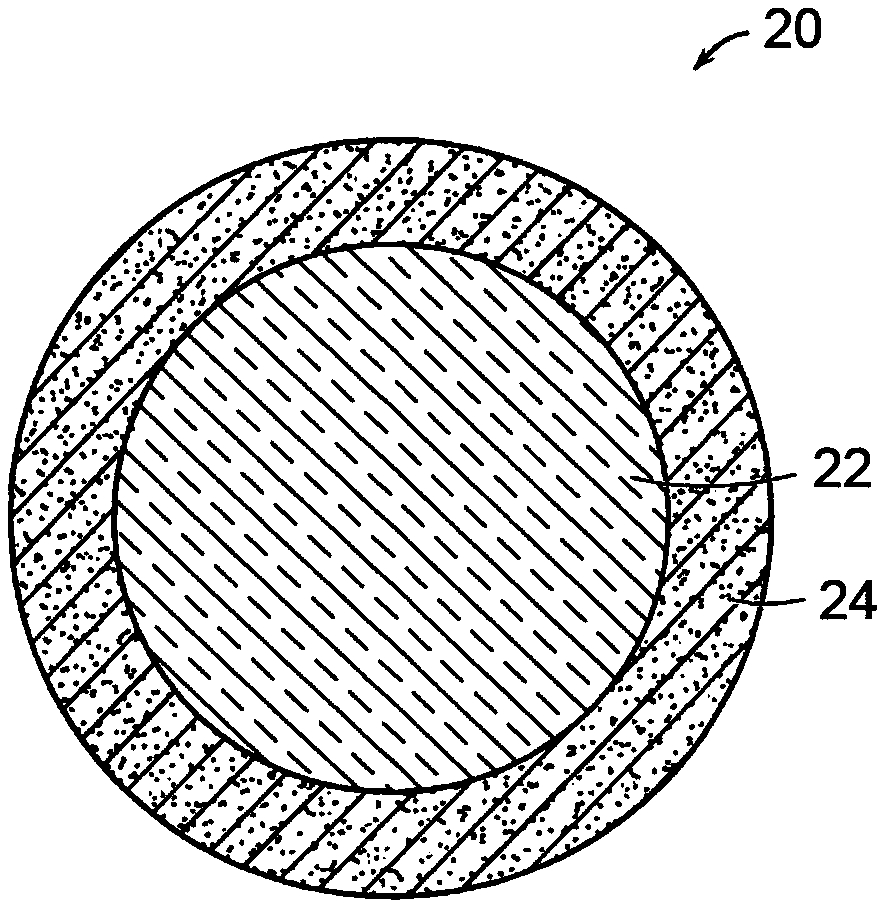

[0025]Golf balls having different configurations can be made in accordance with this invention. For example, golf balls can be manufactured in three-piece, four-piece and five-piece constructions with single or multiple layers of cover material. Representative examples of such golf ball configurations are provided and discussed further below. As used herein, the term "layer" generally refers to any spherical portion of a golf ball. More specifically, in one form, a two-piece golf ball is manufactured that includes a core and a surrounding cover. It is also possible to manufacture three-piece golf balls with a double core and a single cov...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com