High efficient and anti-coking cyclone separator

A technology of cyclone separator and air inlet, which is applied in the direction of cyclone device and the device whose axial direction of the cyclone can be reversed, etc. It can solve the problem of destroying the centrifugal flow field of the separator, unable to completely solve the coking of the separator, and reduce the separation efficiency, etc. problems, to achieve the effect of ensuring long-term safe operation, simple structure, and improving separation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

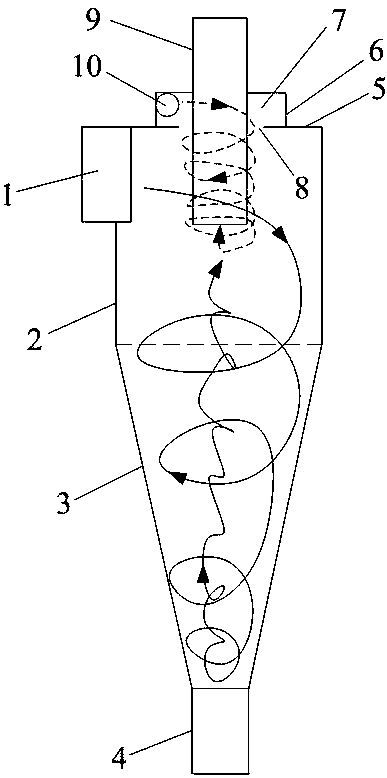

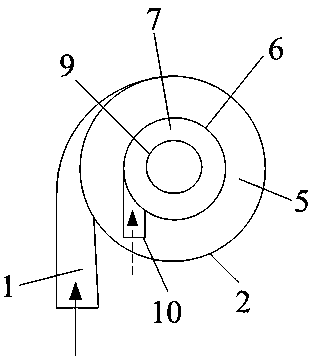

[0022] Embodiment 1: see figure 1 and 2 , the cyclone separator of the present invention consists of a tangential feed port 1, a cylinder body 2, a cone body 3, a material leg 4, a cylinder body top plate 5, a cylinder cavity 6 above the cylinder body, an exhaust pipe 9, and a cylinder cavity The tangential air inlet 10 of the body is formed. The gas carries particles into the separator from the tangential inlet 1, and the clean gas enters the air chamber 7 through the tangential inlet 10 and forms a swirling airflow, enters the separator through the annular gap 8, and rotates downward around the outer wall of the exhaust pipe 9. A rotating air cushion layer is formed on the outer wall of the exhaust pipe, and finally enters the inside of the exhaust pipe through the inlet at the bottom of the exhaust pipe 9 .

Embodiment 2

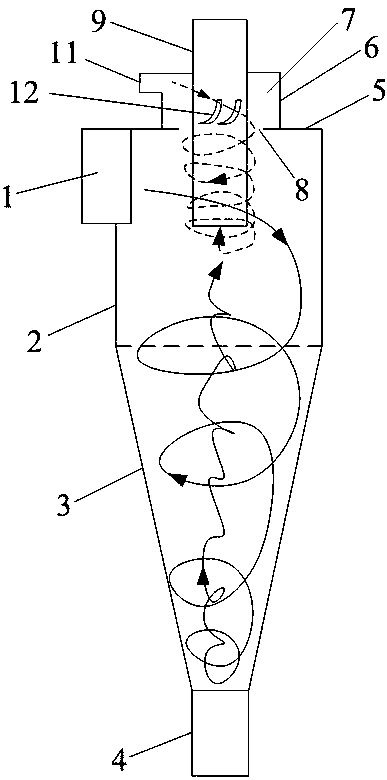

[0023] Example 2: see image 3 and 4 , the cyclone separator of the present invention consists of a tangential feed port 1, a cylinder body 2, a cone body 3, a material leg 4, a cylinder body top plate 5, a cylinder cavity 6 above the cylinder body, an exhaust pipe 9, and a cylinder cavity Body radial air inlet 11, guide vanes 12 constitute. The gas carries particles into the separator from the tangential feed port 1, and the clean gas enters the air chamber 7 through the radial air inlet 11, forms a rotating air flow under the action of the guide vane 12, enters through the annular gap 8 and goes around the exhaust pipe 9 The outer wall rotates downward to form a rotating air cushion layer on the outer wall of the exhaust pipe, and finally enters the inside of the exhaust pipe through the inlet at the bottom of the exhaust pipe 9 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com