Preparation method of fiber pervious recycled aggregate concrete

A technology of permeable concrete and recycled aggregates, applied in the field of construction engineering, can solve the problems of incomplete research and other problems, achieve the effects of improving weak joint surfaces, alleviating urban waterlogging problems, and improving overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-3

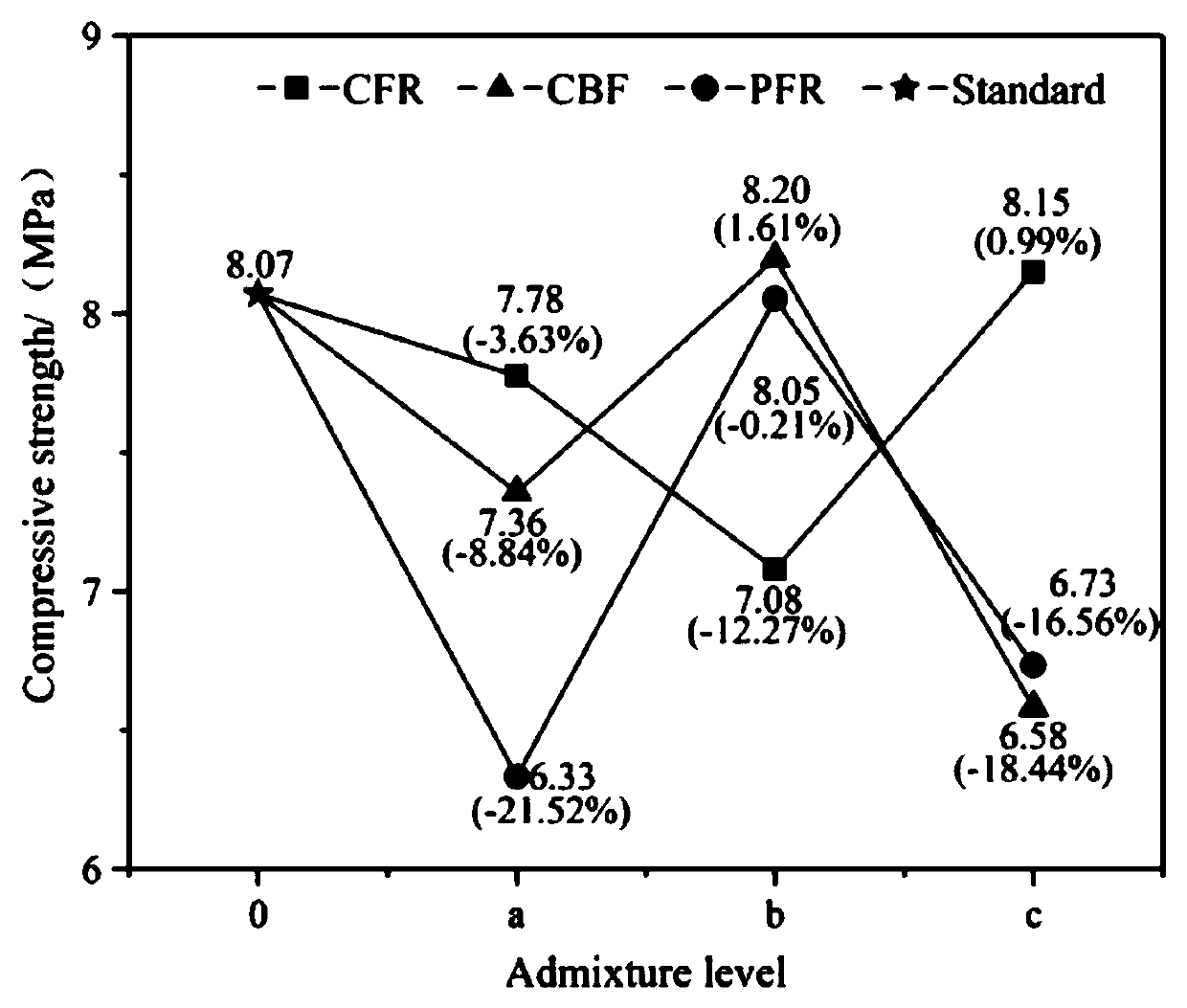

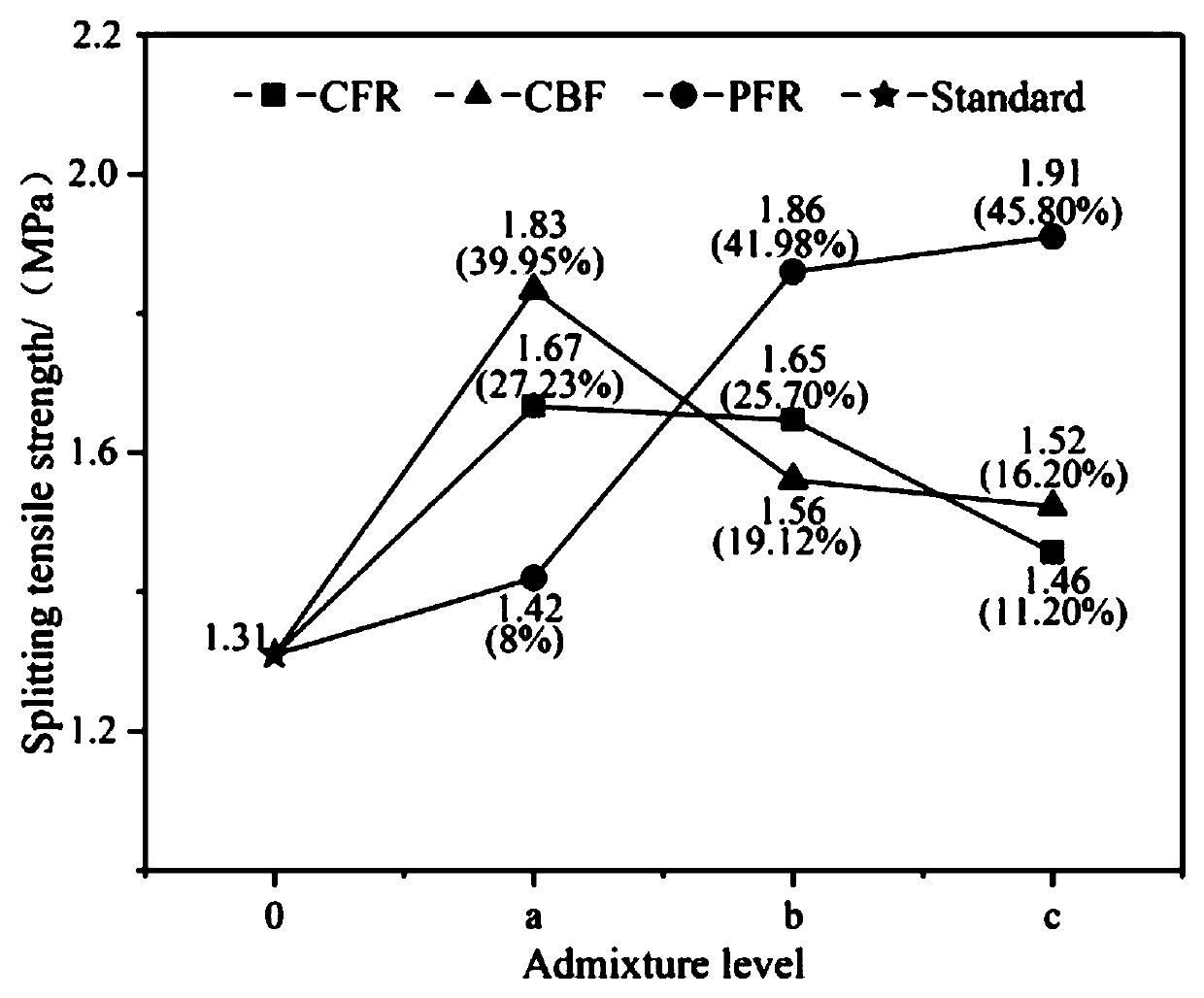

[0036] Embodiment 1-3: Comparative analysis of the composition of three different fibers through experiments, and the comparative analysis of compressive strength, compressive splitting tensile strength and compressive splitting tensile strength are as follows.

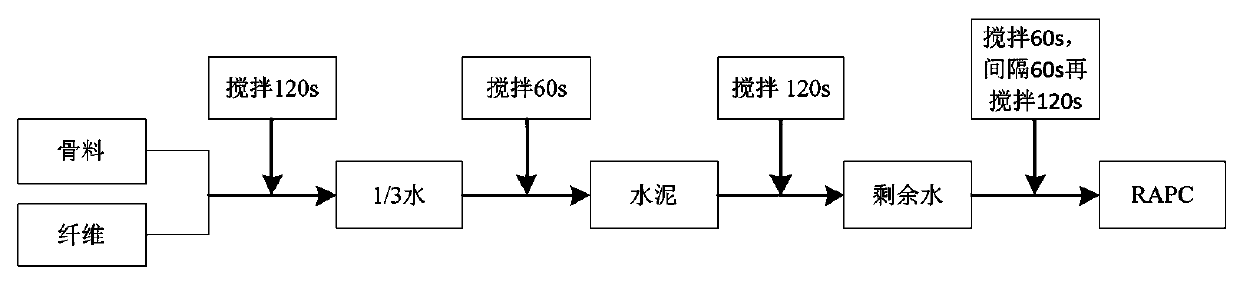

[0037] 1 test procedure

[0038] 1.1 Test materials and mix ratio

[0039] The raw materials required for this test include mixing water (tap water), recycled aggregates are crushed from the C20 waste concrete pavement by a jaw crusher, and the aggregates with a particle size of 9.5-19.5 mm are screened to select chopped basalt fibers. (CBF), chopped carbon fiber (CFR) and polypropylene fiber (PFR), the water-binder ratio of recycled aggregate permeable concrete is set to 0.3, and the bone-binder ratio is 4.5. The detailed mix ratio and number are shown in Table 1. For the convenience of analysis, the three kinds of fibers mixed with recycled aggregate permeable concrete are uniformly coded according to the dosage le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com