Method for preparing 2,2,3,3,3-pentafluoro-1-propanol

A technology of pentafluoropropanol and pentafluoropropionate, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of complex operation, difficult industrialization, and many synthesis steps, and meet the reaction conditions Mild, less synthetic steps, easy to obtain raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The catalyst in the present invention is M-KF / Al 2 O 3 The preparation methods include:

[0016] (1) Transfer 20g pseudo-boehmite into 200Ml EG to form a suspension;

[0017] (2) Under the water bath temperature of 60℃ and magnetic stirring, quickly add 20g potassium fluoride solution and 2g active metal M precursor solution to the suspension described in step (1), and continue stirring for 2h after the addition is complete Then it turns into a semi-solid wet gel;

[0018] (3) The wet gel described in step (2) is aged overnight in an air atmosphere and then transferred to an oven to dry at 110°C for 24 hours to obtain a white dry gel powder that is the M-KF / Al 2 O 3 catalyst.

Embodiment 1

[0020] Into the reactor containing 100g ethyl pentafluoropropionate, slowly add 5g 1% Pt-KF / Al 2 O 3 The catalyst, stirred vigorously, and heated to 50°C, reacted for 4 hours, and the result of gas chromatography analysis showed that the conversion rate was 99.3%, and the selectivity of 2,2,3,3,3-pentafluoropropanol was 90.5%

Embodiment 2~5

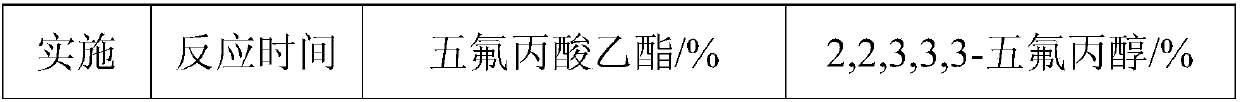

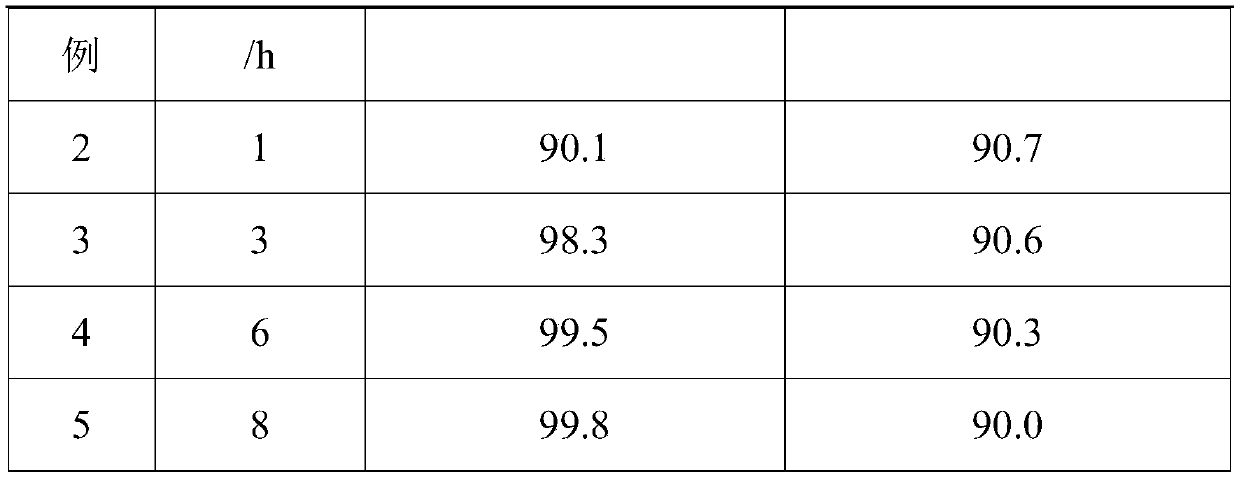

[0022] The method for preparing 2,2,3,3,3-pentafluoropropanol in Examples 2 to 5 is the same as in Example 1, except that the reaction time is changed. The reaction results are shown in Table 1.

[0023] Table 1

[0024]

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com